Film thickness monitoring method of optical film and irregular film system optical film thickness instrument

A technology of optical thin film and film thickness, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of high equipment stability, difficulty in obtaining good repeatability, and cumbersome processing operations. Achieve the effects of eliminating light source fluctuations, improving anti-interference ability, and meeting preparation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

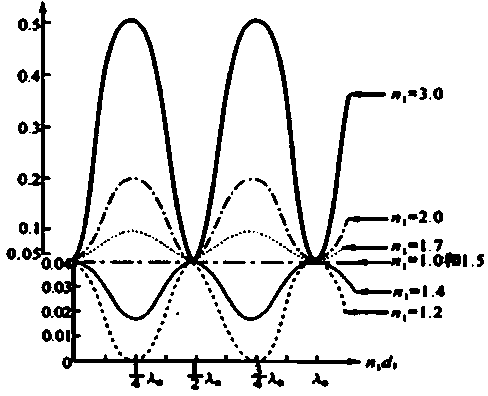

[0042] see figure 1 The optical extremum method is to use the rule that the reflectivity (or transmittance) changes with the film thickness during the deposition process of the film layer, and detect the extreme value of the reflectance (or transmittance) during the deposition process through the photoelectric film thickness monitor Points to monitor films that are integer multiples of a quarter wavelength.

[0043] The traditional optical film thickness meter used: a single optical path is used, and the fluctuation of light source brightness will directly affect the fluctuation of the signal; the film thickness meter selects monochromatic light through a monochromator, and measures the monochromaticity of the optical signal by the monochromator Influenced by itself and the size of the slit, the monochromaticity is worse than that of the laser, the optical signal is weak, and the signal-to-noise ratio is poor; the optical signal is usually received by a photomultiplier tube, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com