Bioreactor for inducing three-dimensional directional differentiation in vitro of stem cells by virtue of non-contact coculture

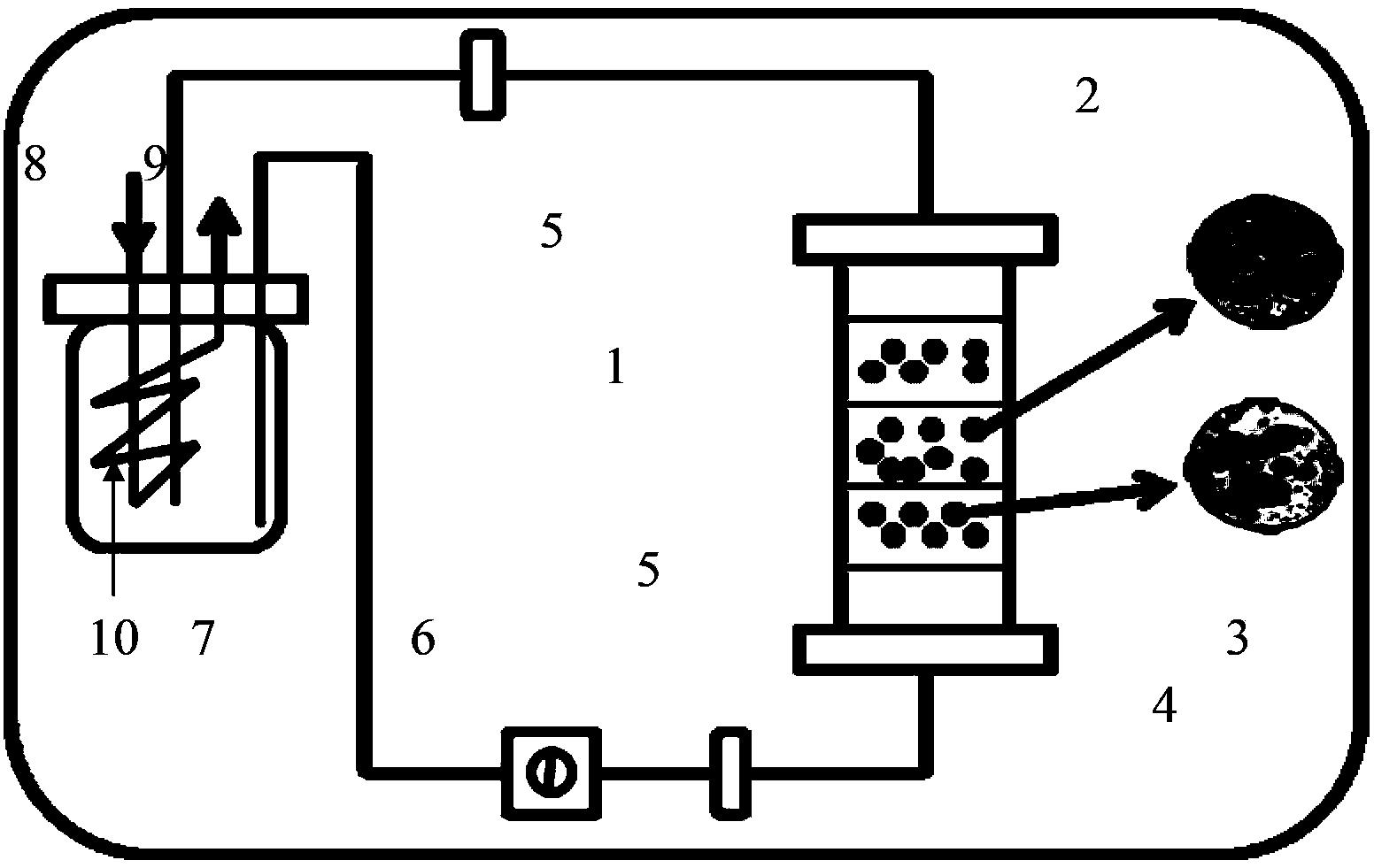

A bioreactor, a technology for inducing cells, applied in specific-purpose bioreactors/fermenters, bioreactor/fermenter combinations, methods of supporting/immobilizing microorganisms, etc., can solve the problems of scale, efficiency and cost. The actual growth conditions of the cells are quite different, and the cells lose their normal biological properties, so as to avoid expensive materials and processes, improve the induction effect, and reduce the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

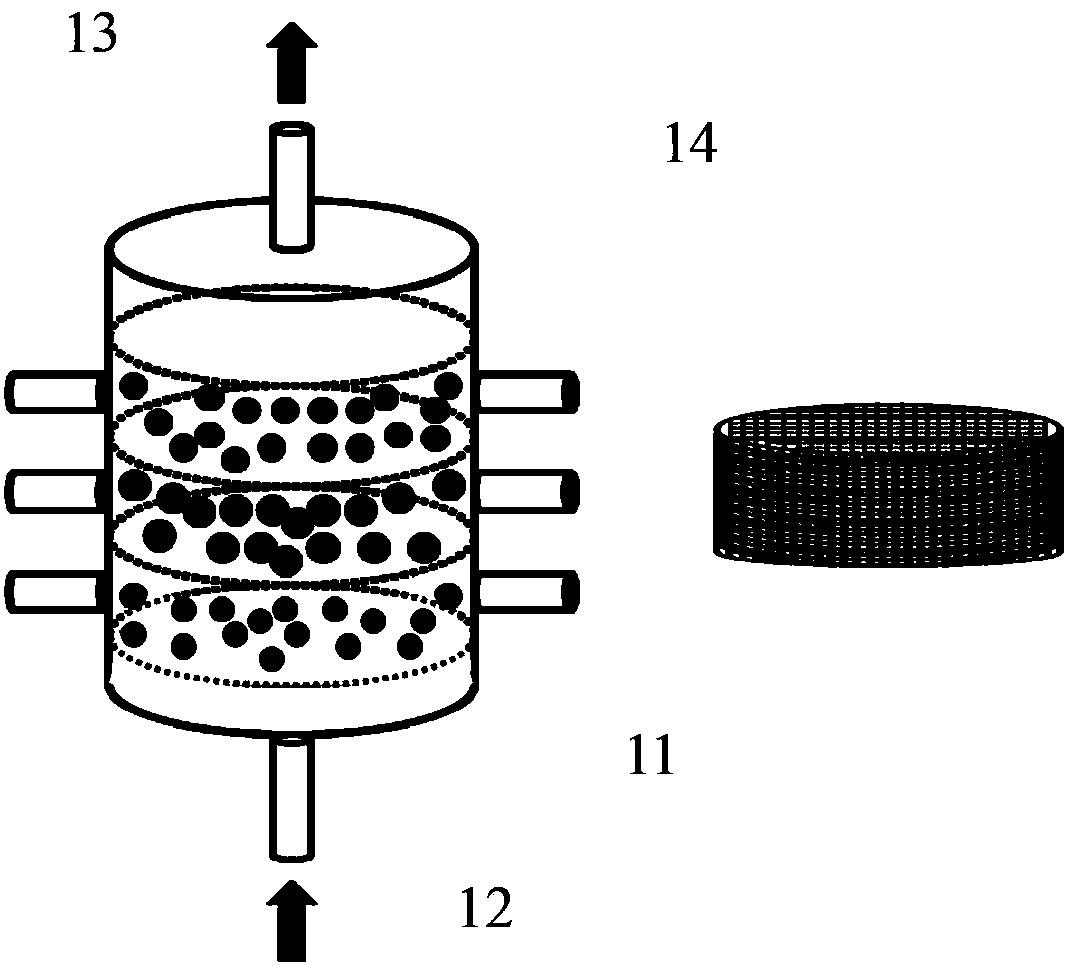

[0052] Example 1: Non-contact dynamic co-culture induces three-dimensional directed differentiation of mesenchymal stem cells into neural precursor cells in vitro

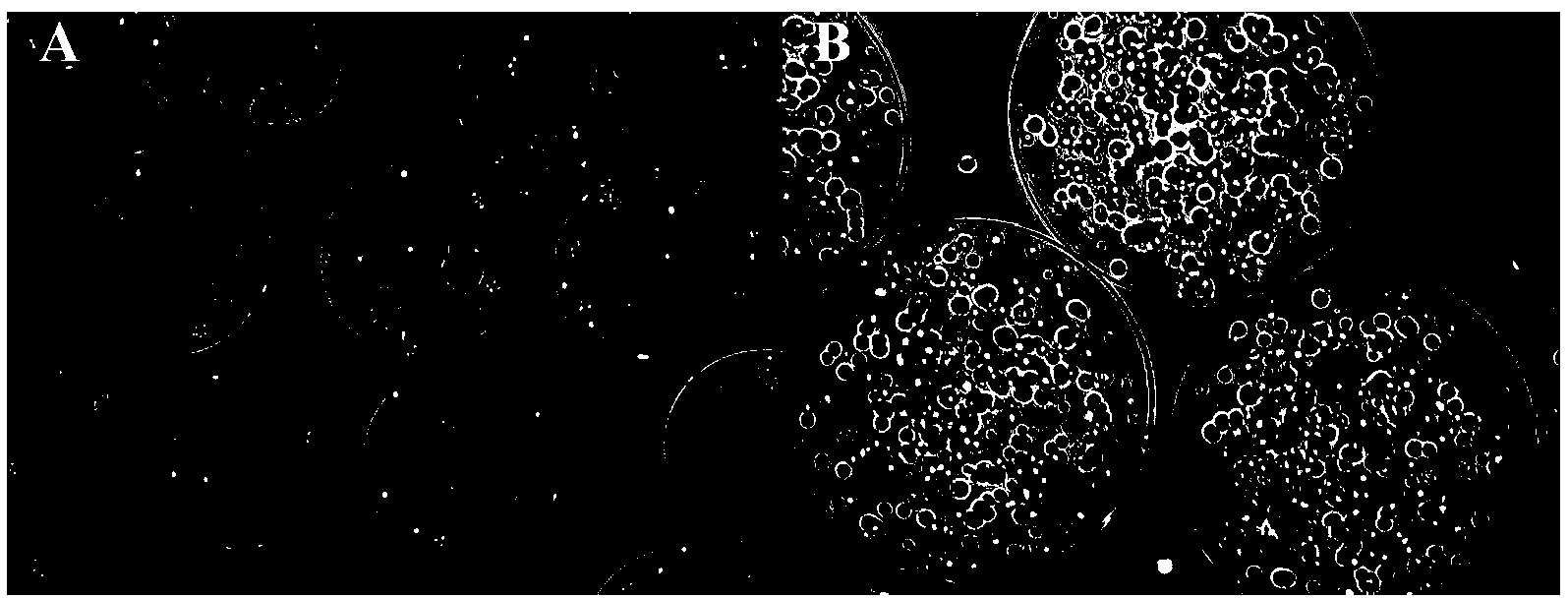

[0053] First, prepare arginyl-glycyl-aspartic acid (RGD), isoleucine-lysine-valine-alanine-valine (IKVAV), tyrosine-isoleucine Sodium alginate modified with acid-glycine-serine-arginine (YIGSR) polypeptide. Sodium alginate (molecular weight 430kDa, ratio of guluronic acid to mannuronic acid 1.5) was dissolved in 0.1M 2-(N-morpholino)ethanesulfonic acid (MES) buffer containing 0.5M NaCl (pH value 6.5), to obtain a 1% (W / V) sodium alginate solution. Then add 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDC), N-hydroxysulfosuccinimide (sulfo-NHS) and a single type of polypeptide, and stir at room temperature for 24 Hour. The molar ratio of EDC to sodium alginate is 1:20, the molar ratio of EDC to sulfo-NHS is 2:1, and the mass ratio of polypeptide to sodium alginate is 1:1000. Then dialyzed and freeze-dried to o...

Embodiment 2

[0059] Example 2: Non-contact dynamic co-culture induces three-dimensional directed differentiation of mesenchymal stem cells into myocardial progenitor cells in vitro

[0060] First, arginyl-glycyl-aspartic acid (RGD) modified sodium alginate powder was prepared according to the method in Example 1. Then the RGD-modified sodium alginate powder was dissolved in normal saline, and the concentration of the solution was 1.5% (W / V).

[0061] Mix C2C12 cells with 1.5% (W / V) RGD-modified sodium alginate solution, and adjust the cell density to 2×10 6 cells mL -1 , the cell suspension was dripped into 100mmol·L via a syringe pump -1 CaCl 2 The solution was calcified for 20 minutes to obtain calcium alginate microgel beads. The calcium alginate microgel beads were reacted with 0.5% (W / V) chitosan with a molecular weight of 60,000 to form a film for 10 minutes to form a non-liquefied sodium alginate / chitosan microcapsule film, and then mixed with 0.15% (W / V ) sodium alginate solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com