Purification method of waste emulsified oil

A technology of emulsified oil and oil layer, applied in the direction of lubricating composition, etc., can solve the problems of waste of resources, environmental pollution, lack of economical and effective means, etc., and achieve the effect of high recycling rate, low one-time investment and stable treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

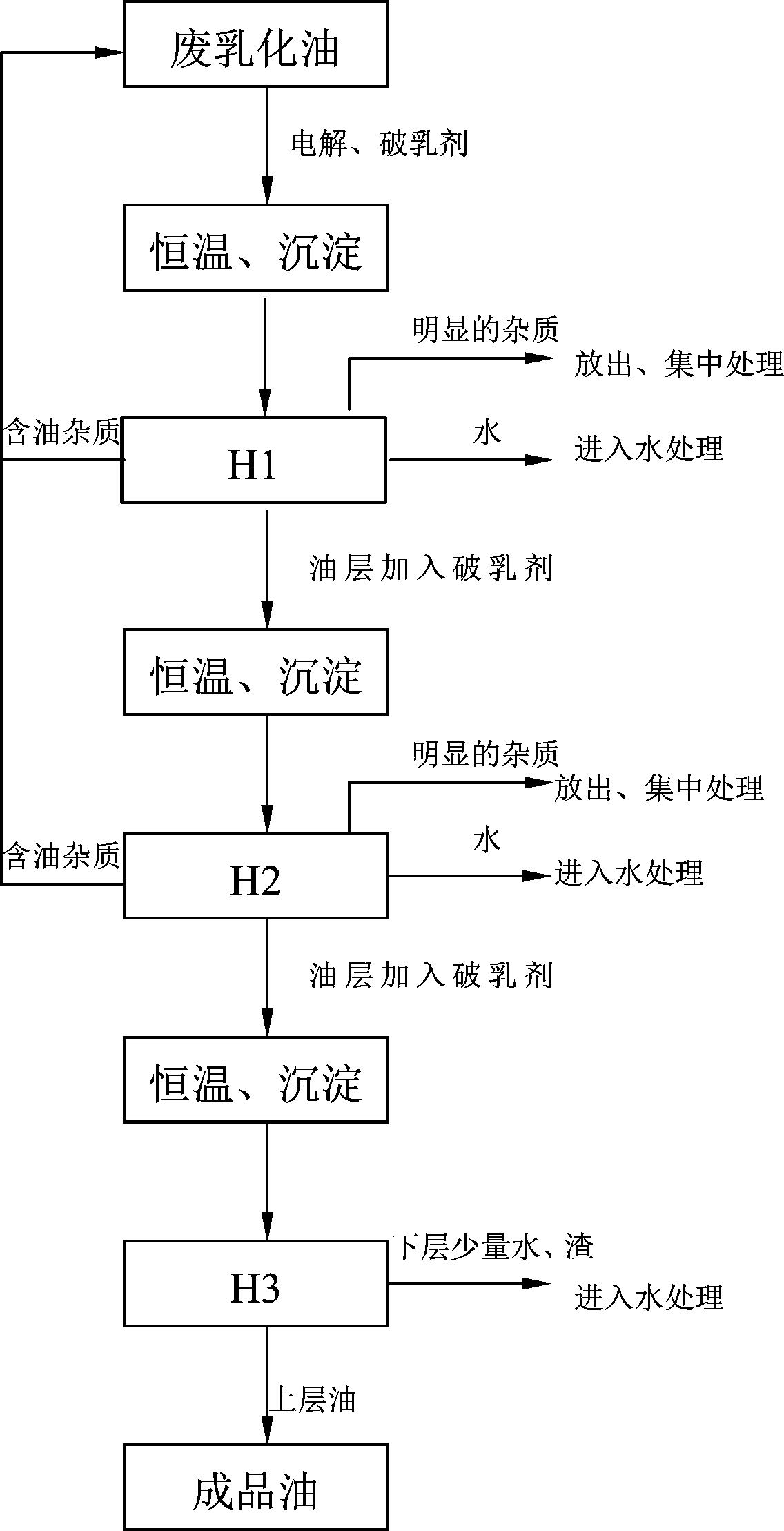

[0019] A method for purifying waste emulsified oil, comprising three steps of pretreatment, comprehensive reaction and deep reaction, such as figure 1 As shown, proceed as follows:

[0020] During pretreatment, first heat the waste emulsified oil to 60°C, and then put the heated waste emulsified oil to settle for no less than 8 hours, so that the internal mixed solid impurities can be precipitated. Filter and remove, inflate and stir the filtered waste emulsified oil under the pressure of at least 0.2MPa, and the inflating and stirring time should not be less than 30min to complete the pretreatment;

[0021] In the comprehensive reaction, high-voltage electrolysis is first performed on the waste emulsified oil that has completed the pretreatment. The voltage during electrolysis is 10kV, the electrolysis time is 100min, and the precipitation is at least 30min after the end. Emulsion, inflated and stirred for 10min to 15min under at least 0.2MPa air pressure, inflated and stirr...

Embodiment 2

[0026] A method for purifying waste emulsified oil, comprising three sequential steps of pretreatment, comprehensive reaction and deep reaction,

[0027] During pretreatment, first heat the waste emulsified oil to 68°C;

[0028] In the comprehensive reaction, the voltage during electrolysis is 18kV, and the electrolysis time is 116min;

[0029] In the comprehensive reaction, catalyst one selects the H that the mass percent concentration is 82%. 3 PO 4 , H 3 PO 4 The quality of the solution is 2.5% of the waste emulsified oil quality; the solute of the demulsifier is a mixture of sodium lauryl sulfate and nonylphenol polyoxyethylene ether, and the quality of sodium lauryl sulfate is nonylphenol polyoxyethylene ether 82% of the mass, the mass percentage concentration of the demulsifier is 8.4%, and the consumption of the demulsifier is 6.4g per L of waste emulsified oil;

[0030] In the deep reaction, the catalyst two selects H2 with a mass percentage concentration of 32%. ...

Embodiment 3

[0033] A method for purifying waste emulsified oil, comprising three sequential steps of pretreatment, comprehensive reaction and deep reaction,

[0034] During pretreatment, first heat the waste emulsified oil to 76°C;

[0035] In the comprehensive reaction, the voltage during electrolysis is 26kV, and the electrolysis time is 132min;

[0036] In the comprehensive reaction, catalyst one selects the H that the mass percent concentration is 84%. 3 PO 4 , H 3 PO 4 The quality of the solution is 3.5% of the waste emulsified oil quality; the solute of the demulsifier is a mixture of sodium lauryl sulfate and nonylphenol polyoxyethylene ether, and the quality of sodium lauryl sulfate is the 99% of the mass, the mass percentage concentration of the demulsifier is 8.8%, and the consumption of the demulsifier is 6.8g per L of waste emulsified oil;

[0037] In the deep reaction, the catalyst two selects H2 with a mass percentage concentration of 34%. 2 o2 , H 2 o 2 The quality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com