Flushing liquid for oil-based drilling fluid well cementation and preparation method thereof

An oil-based drilling fluid and flushing fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems affecting cementing quality and oilfield exploration and development, cement sheath incompatibility, poor interface cementation performance, etc. problems, to achieve the effect of preventing mixing, system stability and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Prepare by 100 parts by weight of fresh water, 5 parts by weight of cleaning agent, 3 parts by weight of cleaning aid, 1 part by weight of chelating agent, 1 part by weight of suspending agent and 20 parts by weight of weighting agent.

[0021] Weigh 70 parts by weight of fresh water, add 1 part by weight of suspending agent at 4000rpm and stir for 3 minutes, dissolve for 30 minutes; add 1 part by weight of chelating agent and 3 parts by weight of cleaning aid at 4000rpm and stir for 10 minutes; Add 20 parts by weight of solid phase particles within 20 seconds and stir for 1 minute; weigh 30 parts by weight of 40°C fresh water and dissolve 5 parts by weight of cleaning agent in the water, and finally mix the cleaning agent solution with the above formulation to prepare a rinse solution.

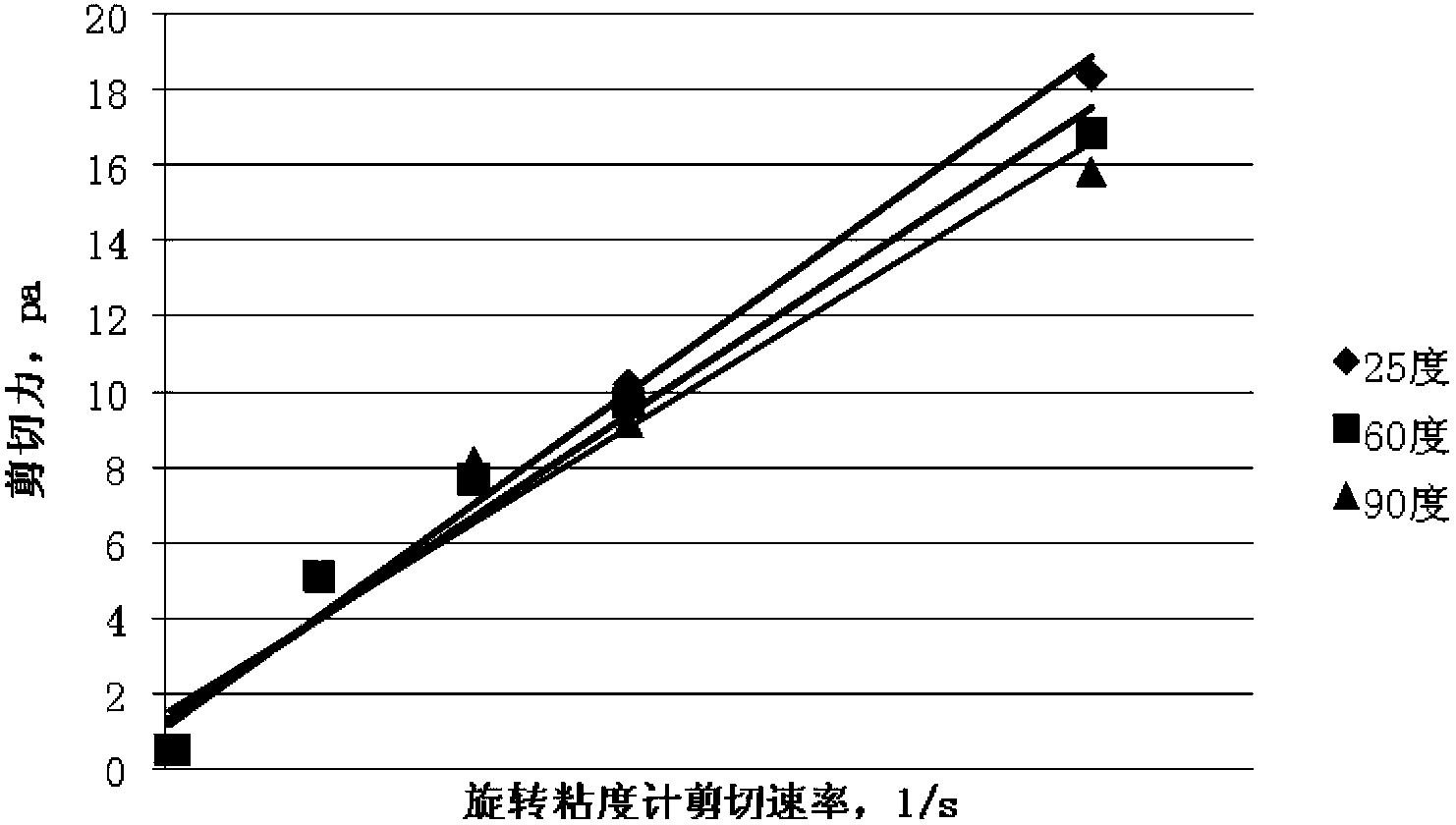

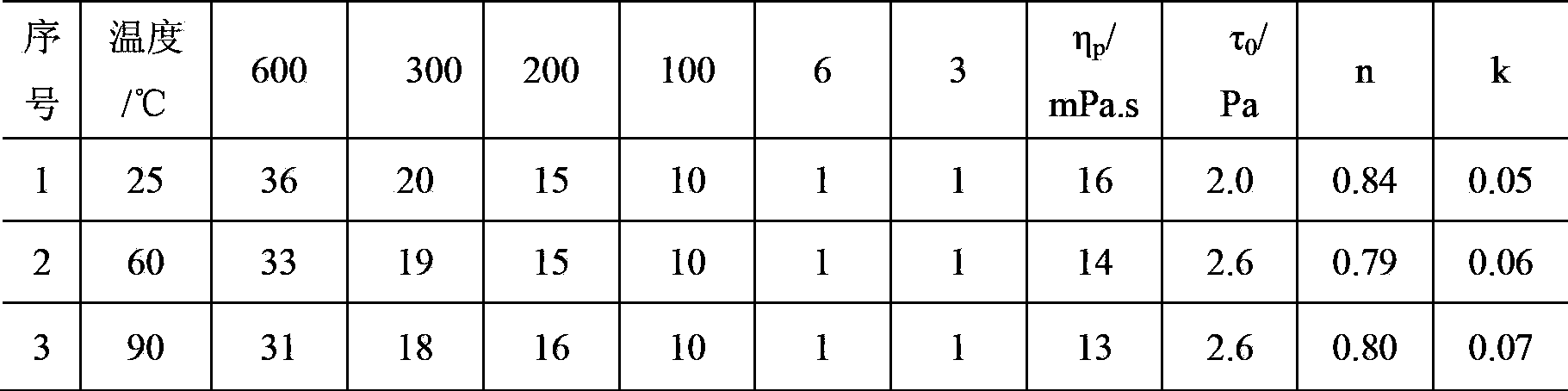

[0022] The measured flushing fluid density is 1.1g / cm 3 , in order to test the rheology and temperature resistance of the flushing agent system, pour the prepared flushing solution int...

Embodiment 2

[0029] Prepare by 100 parts by weight of fresh water, 10 parts by weight of cleaning agent, 6 parts by weight of cleaning aid, 2 parts by weight of chelating agent, 1 part by weight of suspending agent and 20 parts by weight of weighting agent.

[0030] Weigh 70 parts by weight of fresh water, add 1 part by weight of suspending agent at 4000rpm and stir for 3 minutes, dissolve for 30 minutes; add 2 parts by weight of chelating agent and 6 parts by weight of cleaning aid at 4000rpm and stir for 10 minutes; Add 20 parts by weight of solid particles within 20 seconds and stir for 1 minute; weigh 30 parts by weight of fresh water at 40°C and dissolve 5 to 15 parts by weight of cleaning agent in the water, and finally mix the cleaning agent solution with the above formulation evenly to prepare the Flush.

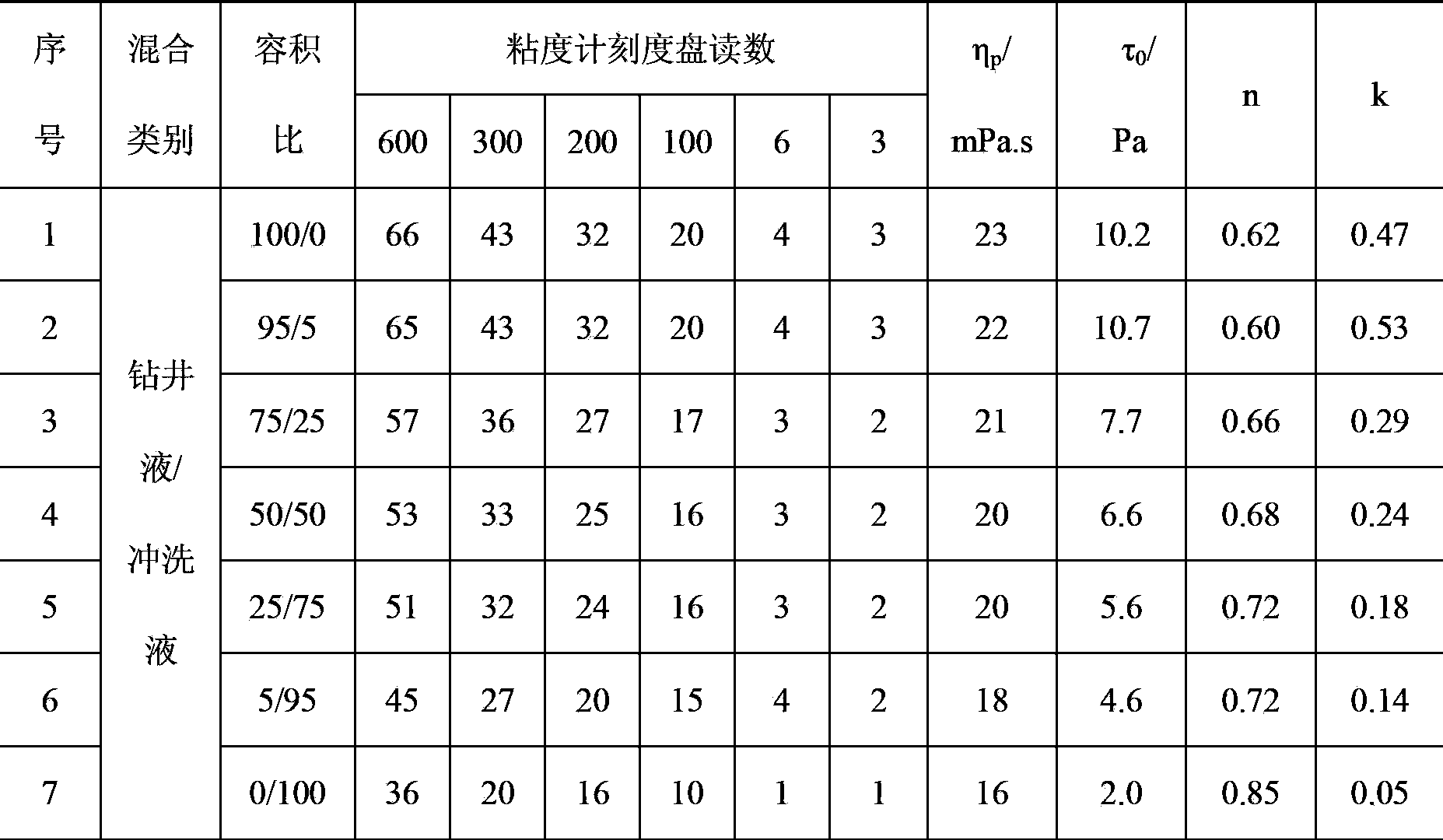

[0031] Pour the prepared oil-based drilling fluid into the slurry cup of the six-speed rotary viscometer, immerse the outer cylinder of the six-speed rotary viscometer in the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com