Polyphenylene sulfide/nylon alloy material and preparation method thereof

A polyphenylene sulfide and alloy material technology, applied in the field of polymer materials, can solve the problem that nylon does not have flame retardancy, and achieve the effects of expanding the scope of application, good flame retardant performance, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

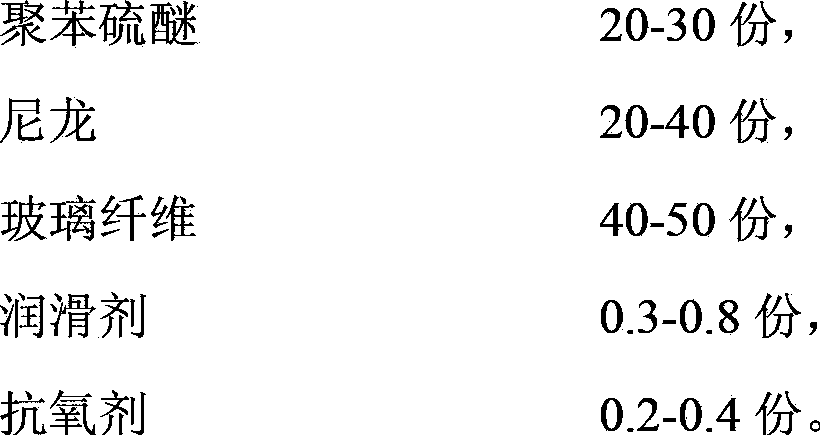

Image

Examples

Embodiment 1

[0024] Mix 20 parts of polyphenylene sulfide, 30 parts of nylon 66, 50 parts of continuous glass fiber (13 μm in diameter), 0.3 parts of silicone, 0.1 part of antioxidant 1010, and 0.1 part of antioxidant 168 through a high-speed mixer, Control the speed of the high-speed mixer to 1000rmp, the temperature to 40°C, and mix for 5 minutes; pour the mixture into the screw extruder, control the temperature of the extruder at 295-310°C, and cut the mixture into strands through the twin-screw extruder pellets to obtain the product.

Embodiment 2

[0026] 30 parts of polyphenylene sulfide, 20 parts of nylon 66, 50 parts of continuous glass fiber (13 μm in diameter), 0.4 parts of ethylene-acrylic acid copolymer wax, 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168, through a high-mixer Mix at high speed, control the speed of the high-speed mixer to 900rmp, and the temperature to 70°C, mix for 10 minutes, pour the mixture into the screw extruder, control the temperature of the extruder at 285-300°C, and pass the mixture through the twin-screw extruder The product can be obtained by cutting the strands into pellets.

Embodiment 3

[0028] 30 parts of polyphenylene sulfide, 40 parts of nylon 66, 45 parts of continuous glass fiber (diameter 13 μm), 0.8 parts of calcium stearate, 0.2 parts of antioxidant 1010, 0.2 parts of antioxidant 168, through a high-speed mixer Mix evenly, control the speed of the high-speed mixer to 950rmp, and the temperature to 40°C, mix for 5 minutes, pour the mixture into the screw extruder, control the temperature of the extruder at 280-310°C, and pull the mixture through the twin-screw extruder The product can be obtained by cutting into pieces.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com