A kind of concrete anti-crack curing agent and preparation method thereof

A technology for concrete and curing agent, applied in the field of concrete curing agent, can solve problems such as inability to meet construction requirements, and achieve the problems of water conservation and maintenance, shrinkage and cracking, improvement of interface strength and wear resistance, and prevention of shrinkage and cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

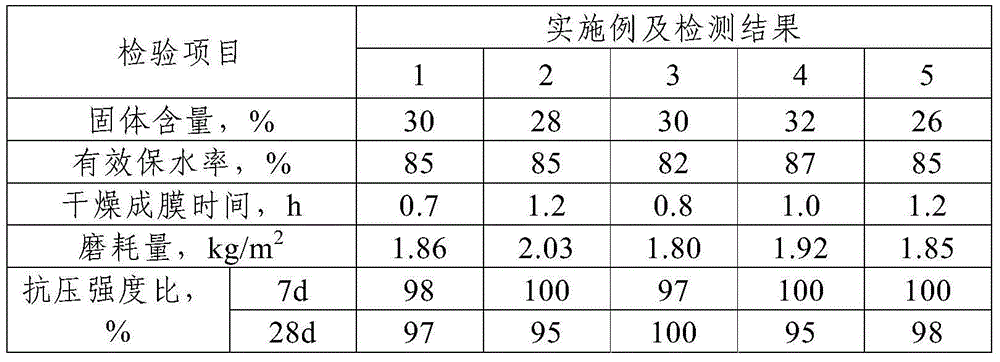

Embodiment 1

[0019] The concrete anti-crack curing agent of the present embodiment is made of the following raw materials in mass percentage: 40% of nano-silica sol, 20% of lithium silicate, 10% of metasilicate, 1% of sodium borate, water-based silane coupling agent (KH- 550) 5%, the balance is deionized water.

[0020] The preparation method is as follows: put 24kg of deionized water, 10kg of metasilicate, 1kg of sodium borate and 5kg of water-based silane coupling agent (KH-550) into the reactor in sequence, stir and react at 60°C for 30min, and then lower the temperature of the reactor to Raise to 85°C, then add 40kg of nano-silica sol and 20kg of lithium silicate into the reaction kettle, and continue to stir and react for 30min to obtain the concrete anti-cracking curing agent.

Embodiment 2

[0022] The concrete anti-crack curing agent of the present embodiment is made of the following raw materials in mass percentage: 30% of nano-silica sol, 25% of lithium silicate, 15% of metasilicate, 2% of sodium borate, water-based silane coupling agent (KH- 560) 2%, and the balance is deionized water.

[0023] The preparation method is as follows: put 26kg of deionized water, 15kg of metasilicate, 2kg of sodium borate and 2kg of water-based silane coupling agent (KH-560) into the reactor in sequence, stir and react at 80°C for 30min, and then lower the temperature of the reactor to Raise to 100°C, then add 30kg nano-silica sol and 25kg lithium silicate into the reaction kettle, continue to stir and react for 30min to obtain concrete anti-crack curing agent.

Embodiment 3

[0025] The concrete anti-crack curing agent of the present embodiment is made of the following raw materials in mass percentage: 50% of nano-silica sol, 15% of lithium silicate, 5% of metasilicate, 0.5% of sodium borate, water-based silane coupling agent (KH- 570) 10%, the balance is deionized water.

[0026] The preparation method is as follows: put 19.5kg deionized water, 5kg metasilicate, 0.5kg sodium borate and 10kg water-based silane coupling agent (KH-570) into the reaction kettle in turn, stir and react at 70°C for 30min, and then put the reaction The temperature of the kettle was raised to 90° C., and then 50 kg of nano-silica sol and 15 kg of lithium silicate were added to the reaction kettle, and the stirring reaction was continued for 30 minutes to obtain a concrete anti-crack curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com