Self-moving corrector

A rectifier, self-moving technology, applied in the direction of conveyor objects, conveyors, transportation and packaging, etc., can solve the problems of inconvenient production, installation deviation, belt manufacturing and joint geometry not straight, etc., to achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and features of the self-moving orthotic proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Efficacy, detailed as follows.

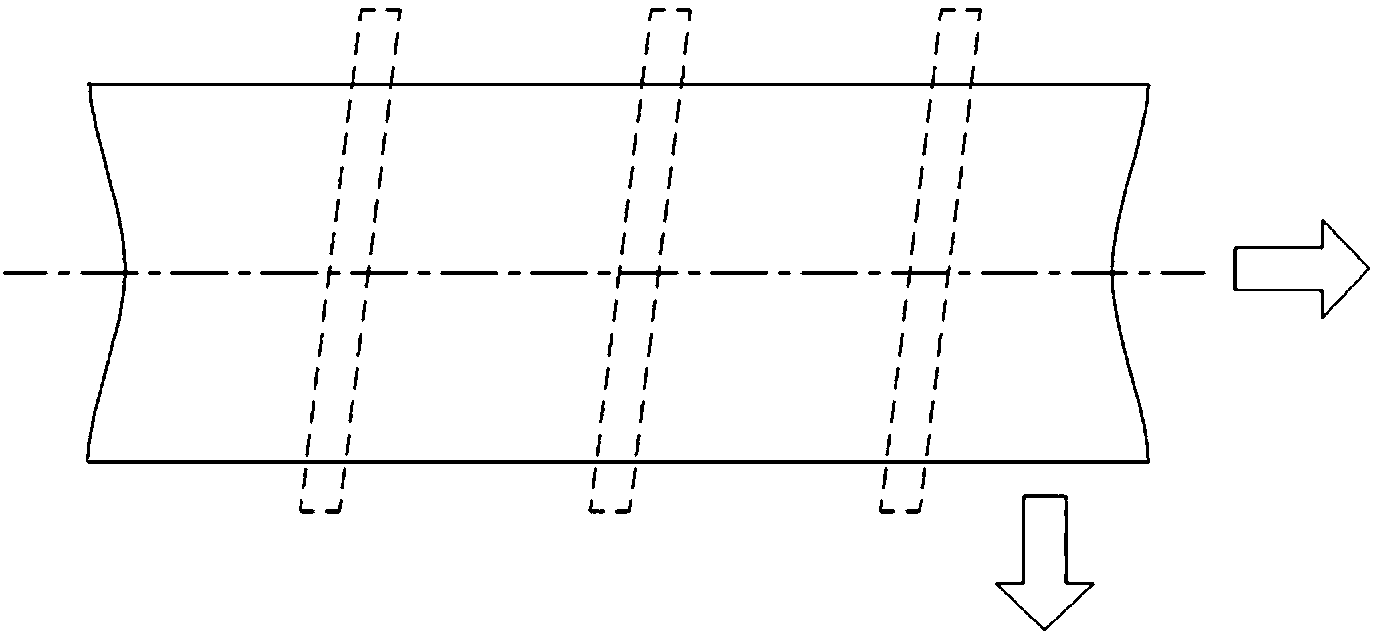

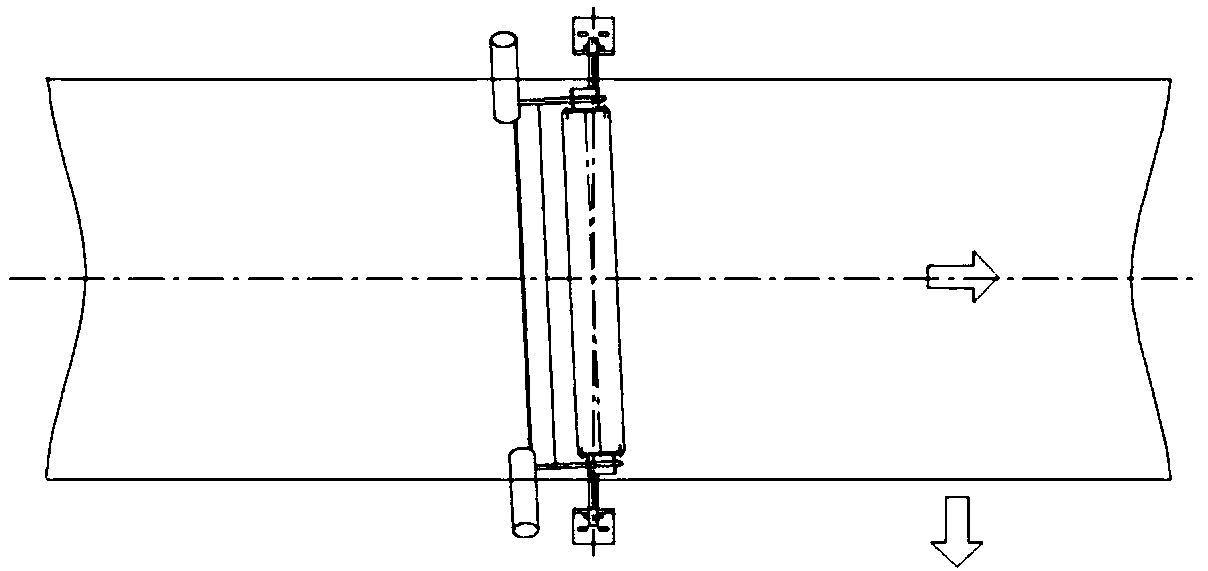

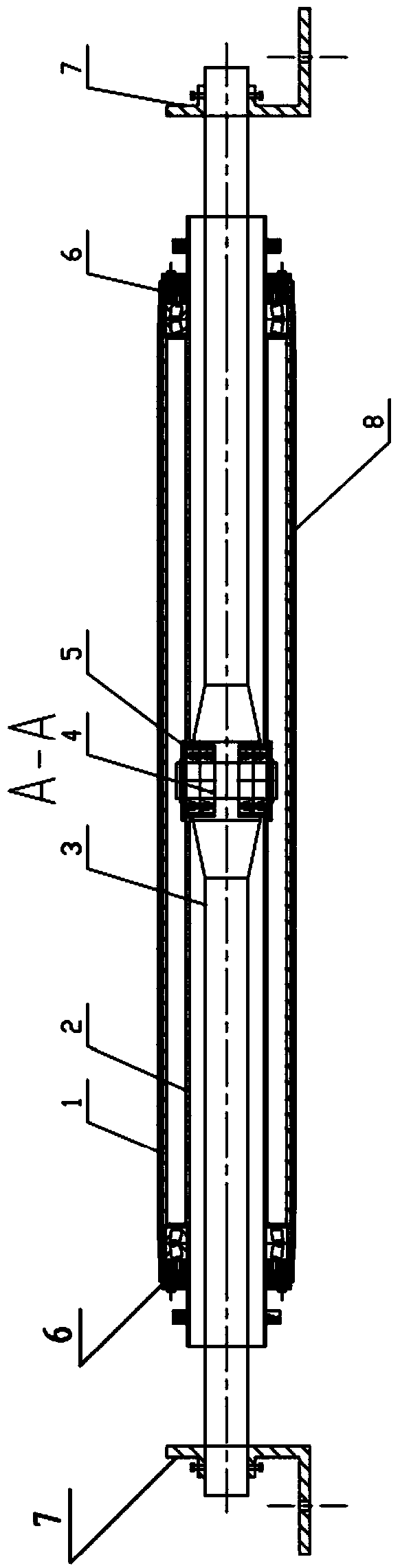

[0034] see figure 1 , figure 2 , image 3 , Figure 4 , figure 1 It is the force analysis diagram of the belt deviation of the self-moving corrector of the present invention. figure 2 It is a working force analysis diagram of the self-moving orthotic of the present invention. image 3 It is A-A sectional view of the self-moving orthotic of the present invention. Figure 4 It is a top view of the self-moving orthotic of the present invention.

[0035] The present invention proposes a self-moving straightener, comprising: a straightening outer cylinder 1, a straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com