Lifting and balancing device for hot press

A balancing device and hot press technology, applied to presses, manufacturing tools, etc., can solve problems such as easy wear, reduced processing accuracy, damage, etc., to avoid wear or damage, avoid increase in error, and ensure level stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

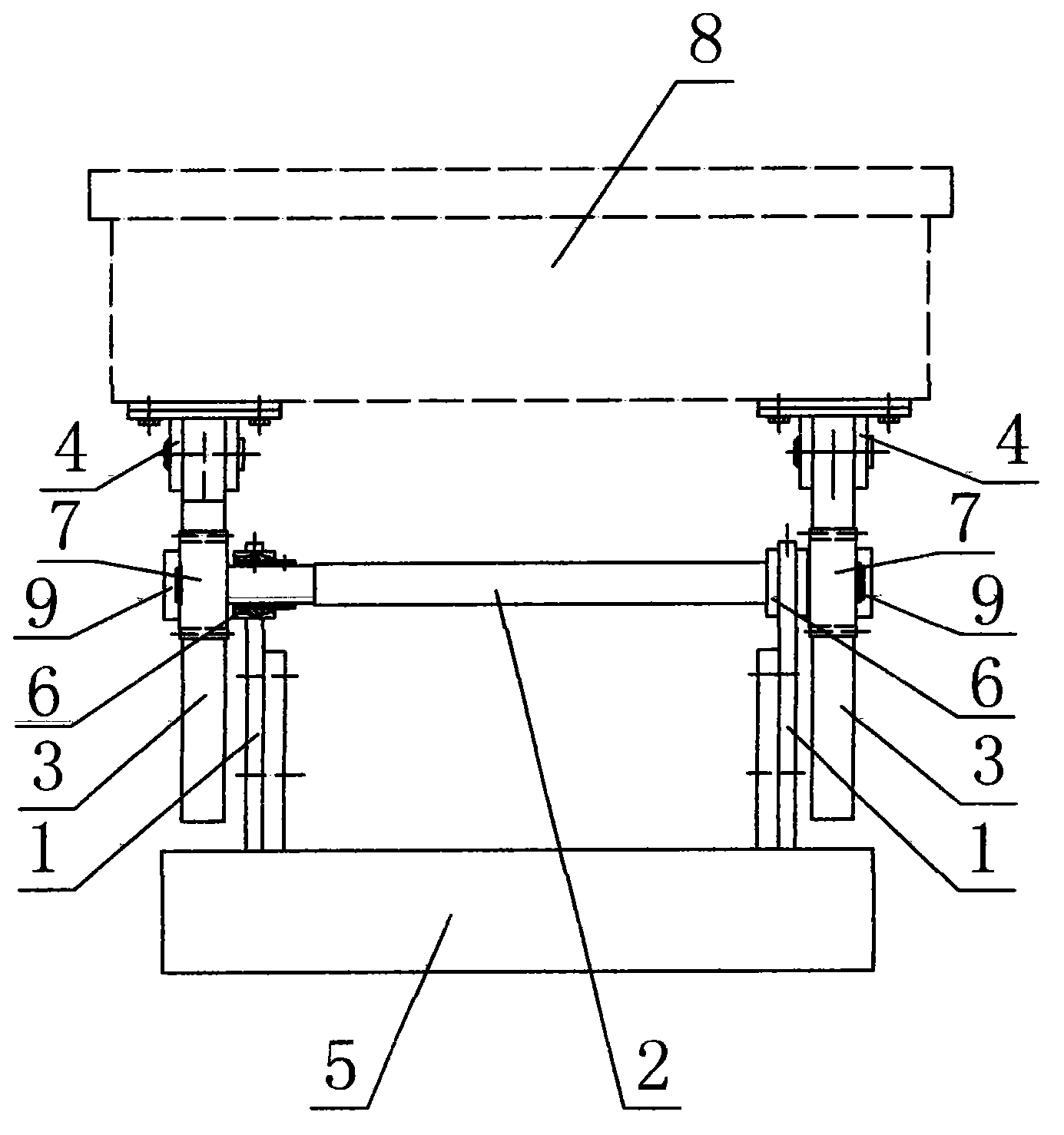

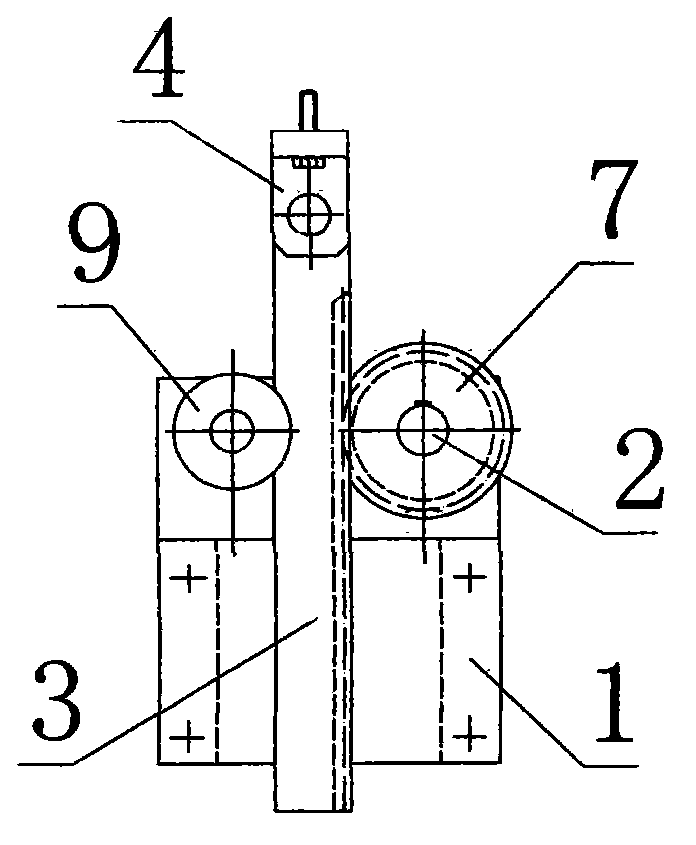

[0009] The hot press lifting balance device of the present invention, such as Figures 1 to 2 As shown, including the base plate 1, the balance bar 2, the balance rack 3, and the connection seat 4, two base plates 1, the balance rack 3, and the connection base 4 are arranged symmetrically. The base plate 1 is installed on the heat press base 5, and the base plate 1 are provided with shaft holes, the shaft holes on the two base plates 1 are symmetrical, bearings 6 are installed in the shaft holes, the balance bar 2 is installed on the two base plates 1 through the two bearings 6, and the two ends of the balance bar 2 are fixedly installed There is a gear 7, and two connection seats 4 are symmetrically installed on the bottom surface of the hot press workbench 8, and the top ends of the two balance racks 3 are hinged on the corresponding connection seats 4, the two balance racks 3 are parallel to each other, and the gears at both ends of the balance bar 2 7 are all meshed with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com