Method for analyzing mechanical property of UD-CMC (Unidirectional Ceramic Matrix Composite) under stress oxidation environment

A composite material, oxidizing environment technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem that the analysis of residual mechanical properties does not consider the effect of stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described below in conjunction with the accompanying drawings.

[0079] The study found that due to the brittleness of the ceramic matrix, the failure process of the UD-CMC matrix under stress is as follows: 1) a "crack source" is formed in the matrix under stress; 2) the "crack source" expands to form cracks; 3 ) A new "crack source" is formed, and the crack continues to expand to become a through crack; 4) The number of cracks no longer increases, and the cracking of the matrix reaches a saturated state.

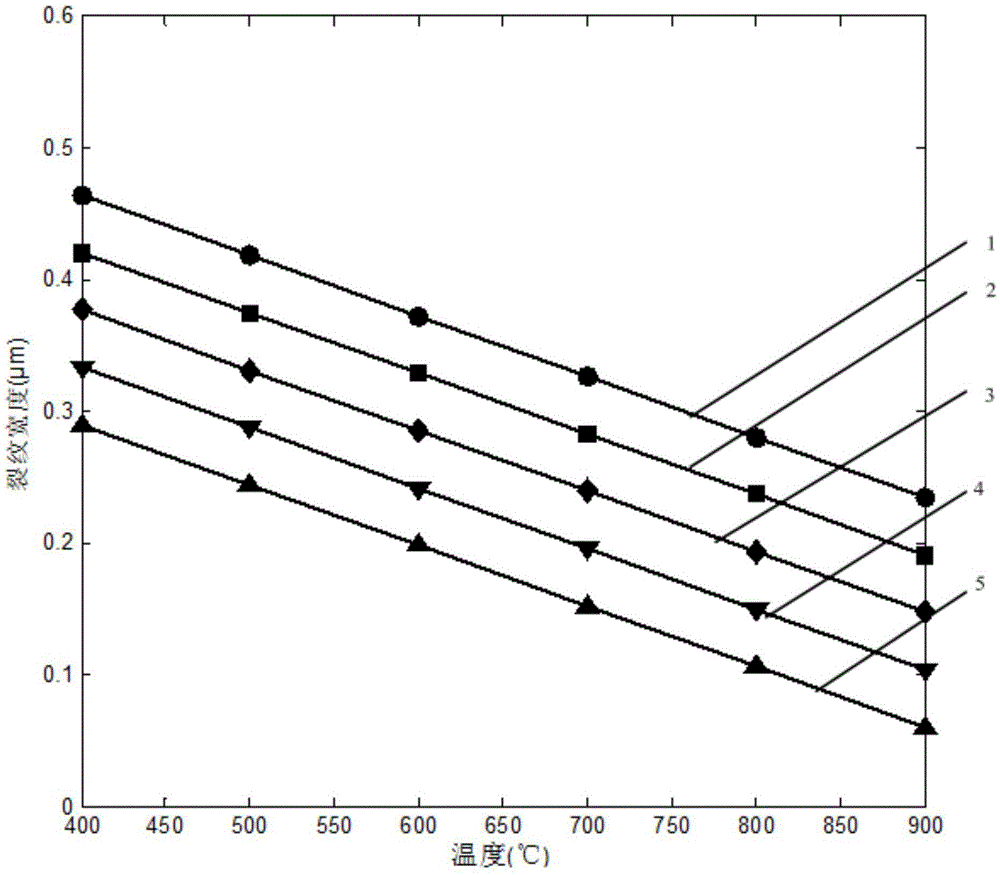

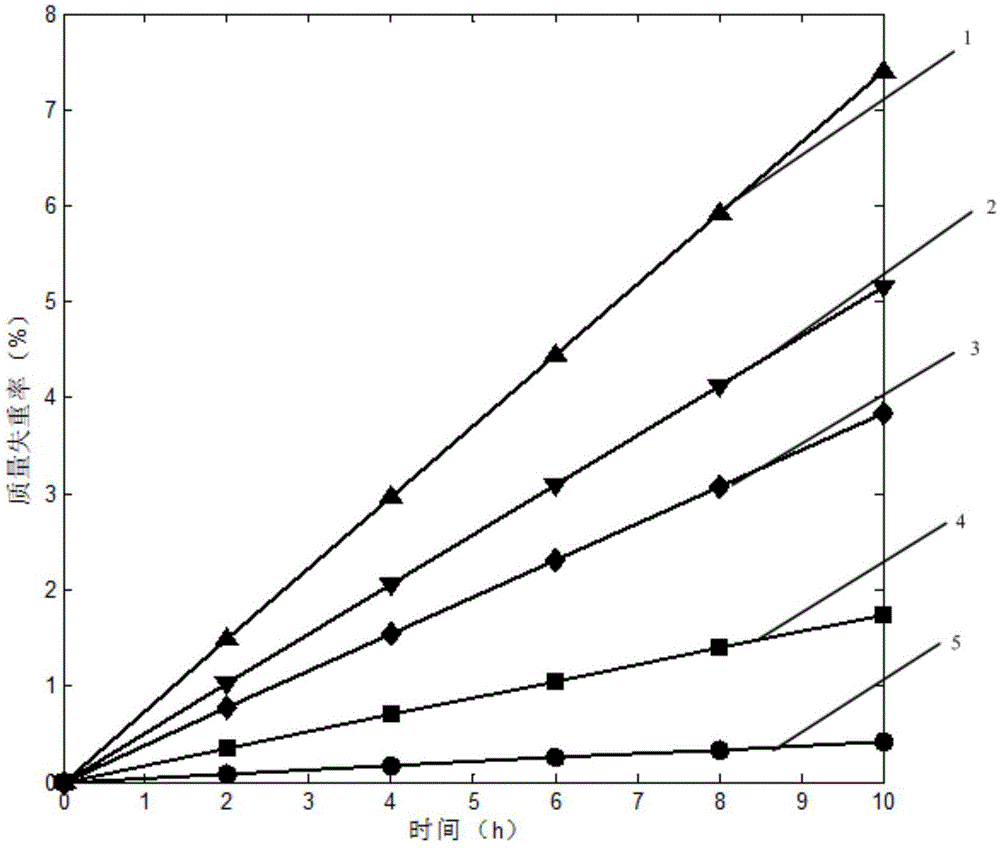

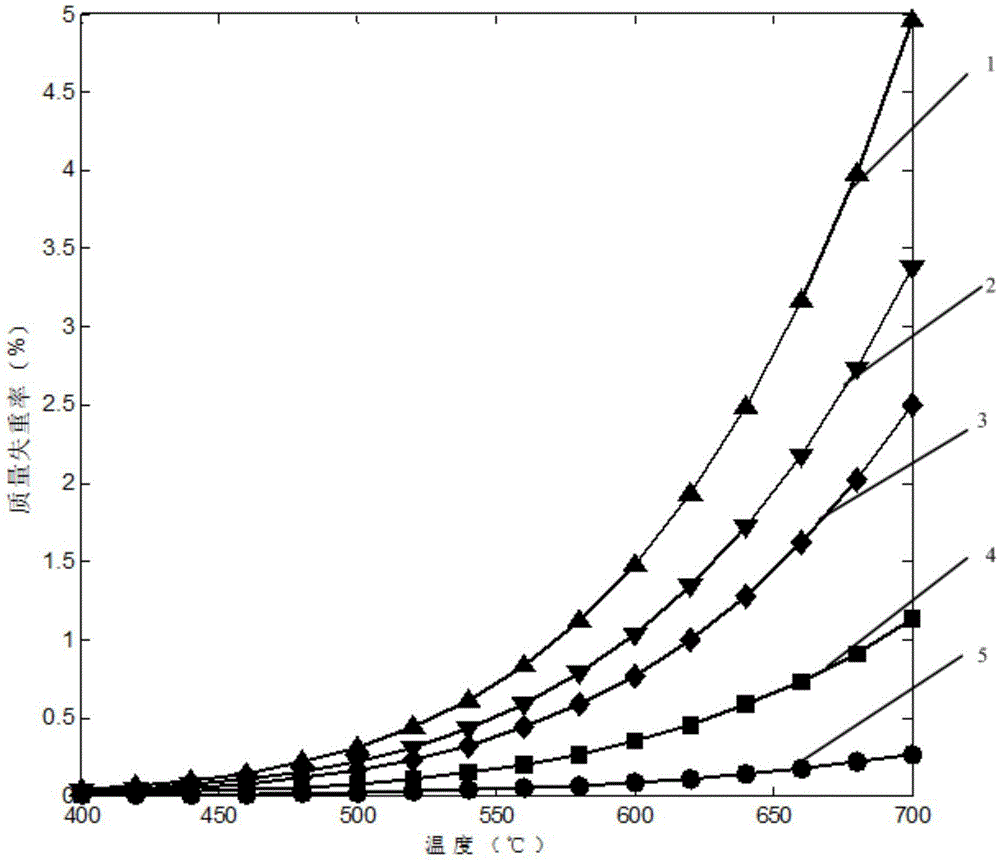

[0080] In the high temperature environment, the effect of stress on the mechanical properties of UD-CMC is mainly reflected in the increase of the effective area of oxidation. There are mainly the following two ways: 1) the number of cracks increases as the stress increases; 2) the crack width increases as the stress increases. Therefore, the present invention mainly divides into the following several steps to the analysis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com