Lateral pre-tightening type rolling and sliding composite guide rail structure

A pre-tightening, pre-tightening mechanism technology, used in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem of difficult to meet the performance indicators and accuracy requirements of heavy machine tools, large sliding guide contact area, vibration resistance, Poor rigidity and other problems, to achieve the effect of uniform force, improved sensitivity, and improved vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

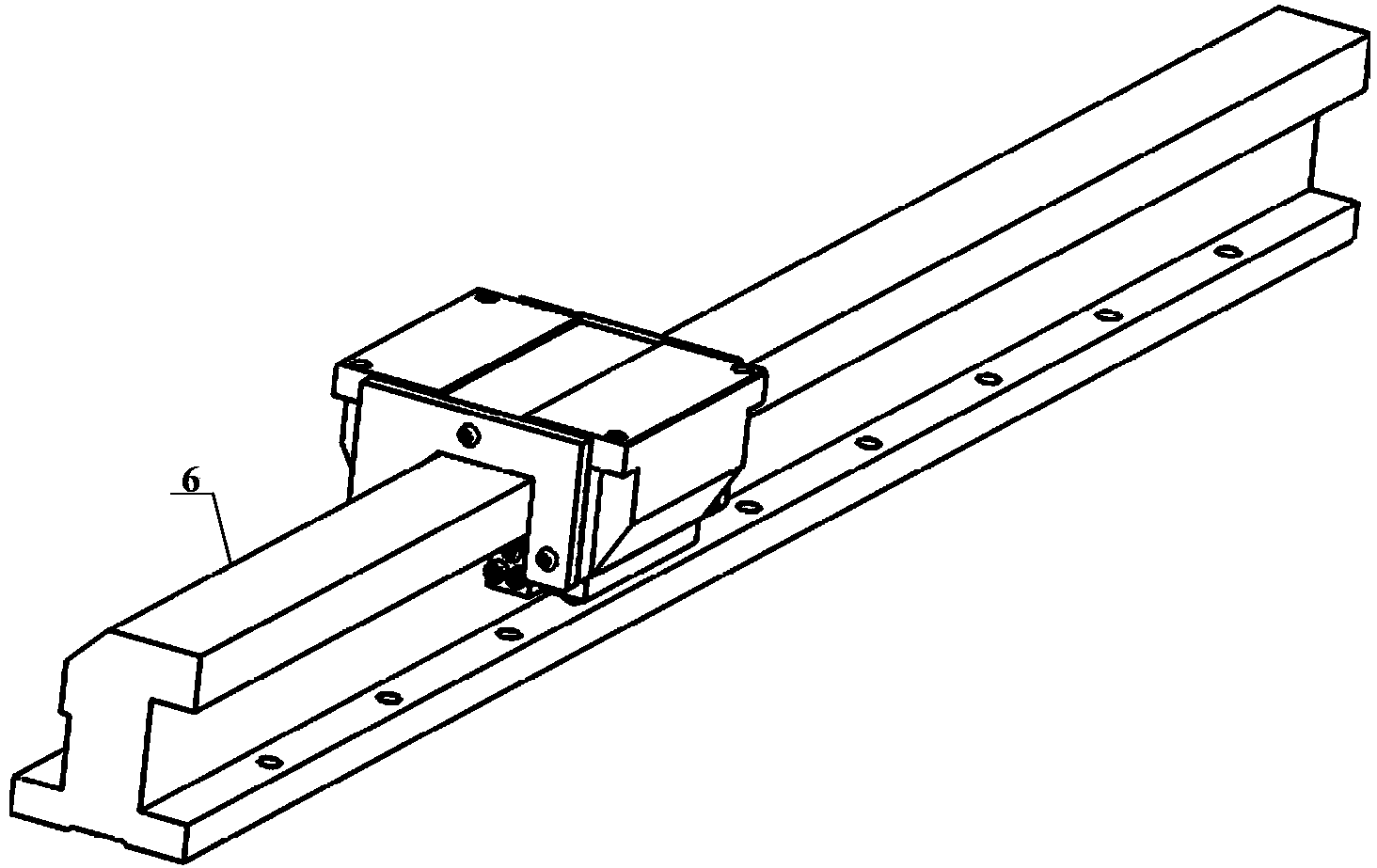

[0021] combine Figure 1 to Figure 4 , a laterally preloaded rolling-sliding compound guide rail structure, including a guide rail 6, a slider and a lateral preload mechanism, the slider is arranged on the guide rail 6, and the lateral preload mechanism is located between the guide rail 6 and the slider ;

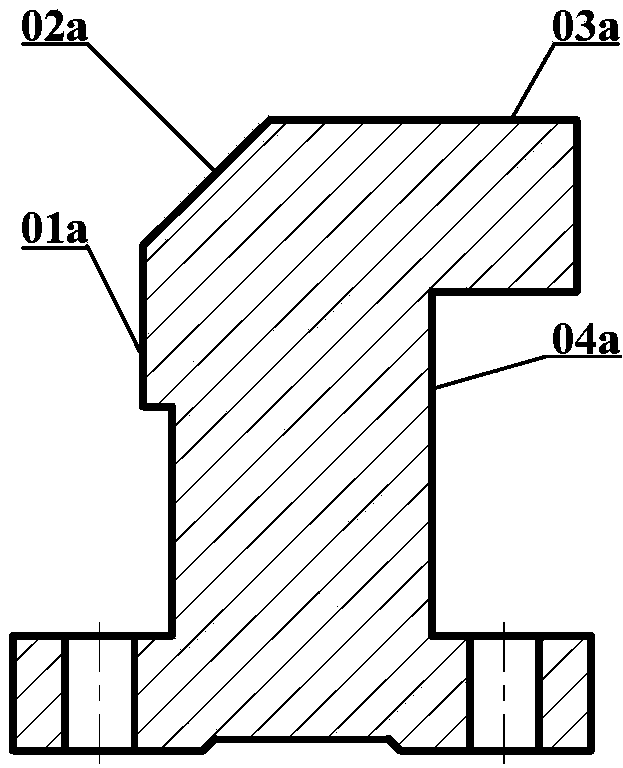

[0022] The left side 01a of the guide rail is a lateral bearing surface, the upper left corner of the guide rail is an inclined surface 02a, the inclined surface is a guiding surface, the upper surface 03a of the guide rail is a normal bearing surface, and the right groove bottom surface 04a of the guide rail is a preload bearing surface;

[0023] The slider includes two end baffles 1 and a slider body 4, the two end baffles 1 are located on the front and rear sides of the slider body 4, the bottom of the slider is provided with a groove matching the guide rail, and the upper part of the groove is Between the surface and the normal bearing surface 03a of the guide rail, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com