Substrate cleaning device and cleaning method

A technology for cleaning devices and substrates, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as high cleaning costs and long cleaning process cycles, and achieve reduced process costs and improved cleaning effects , The effect of saving the space occupied by the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

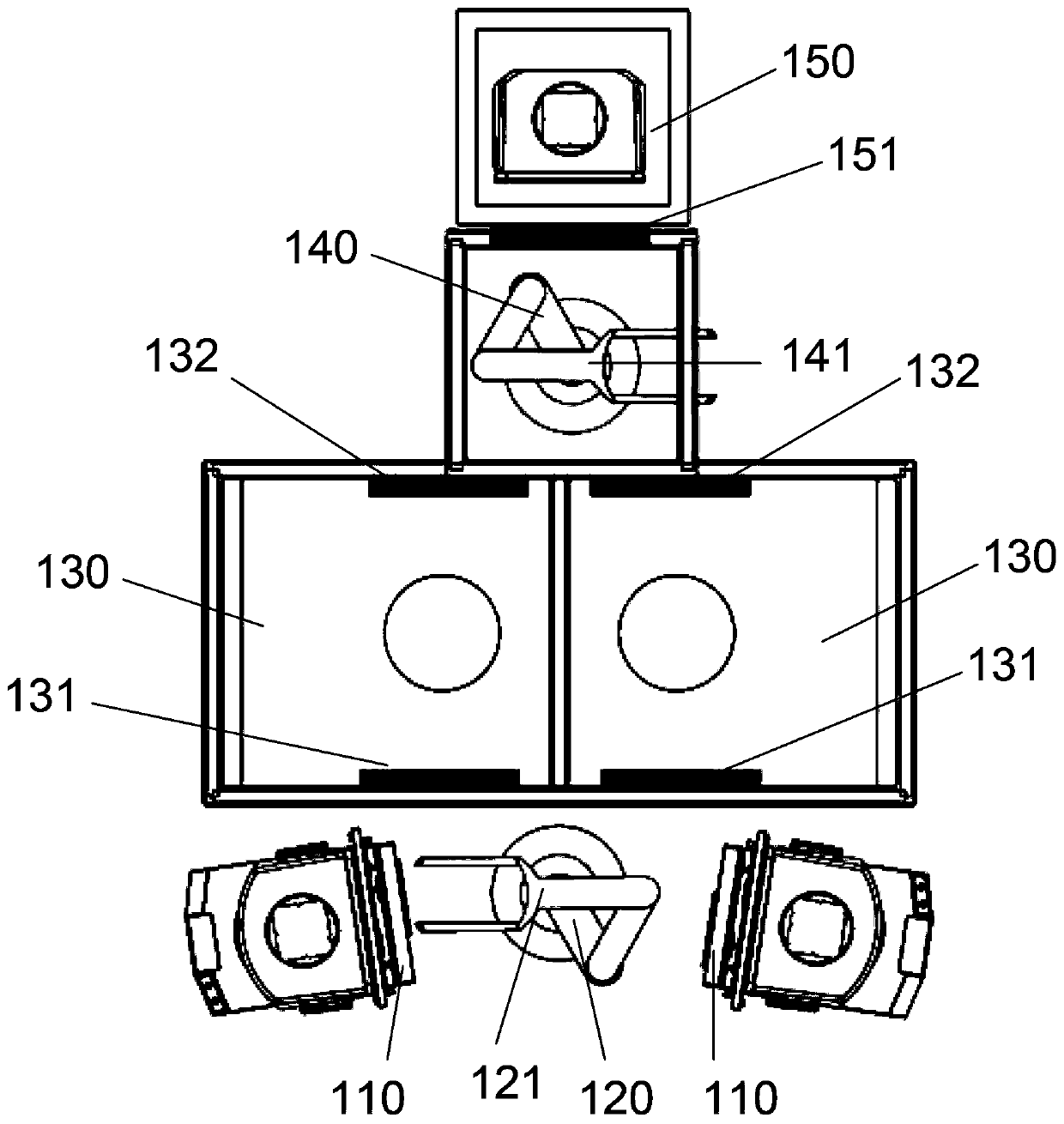

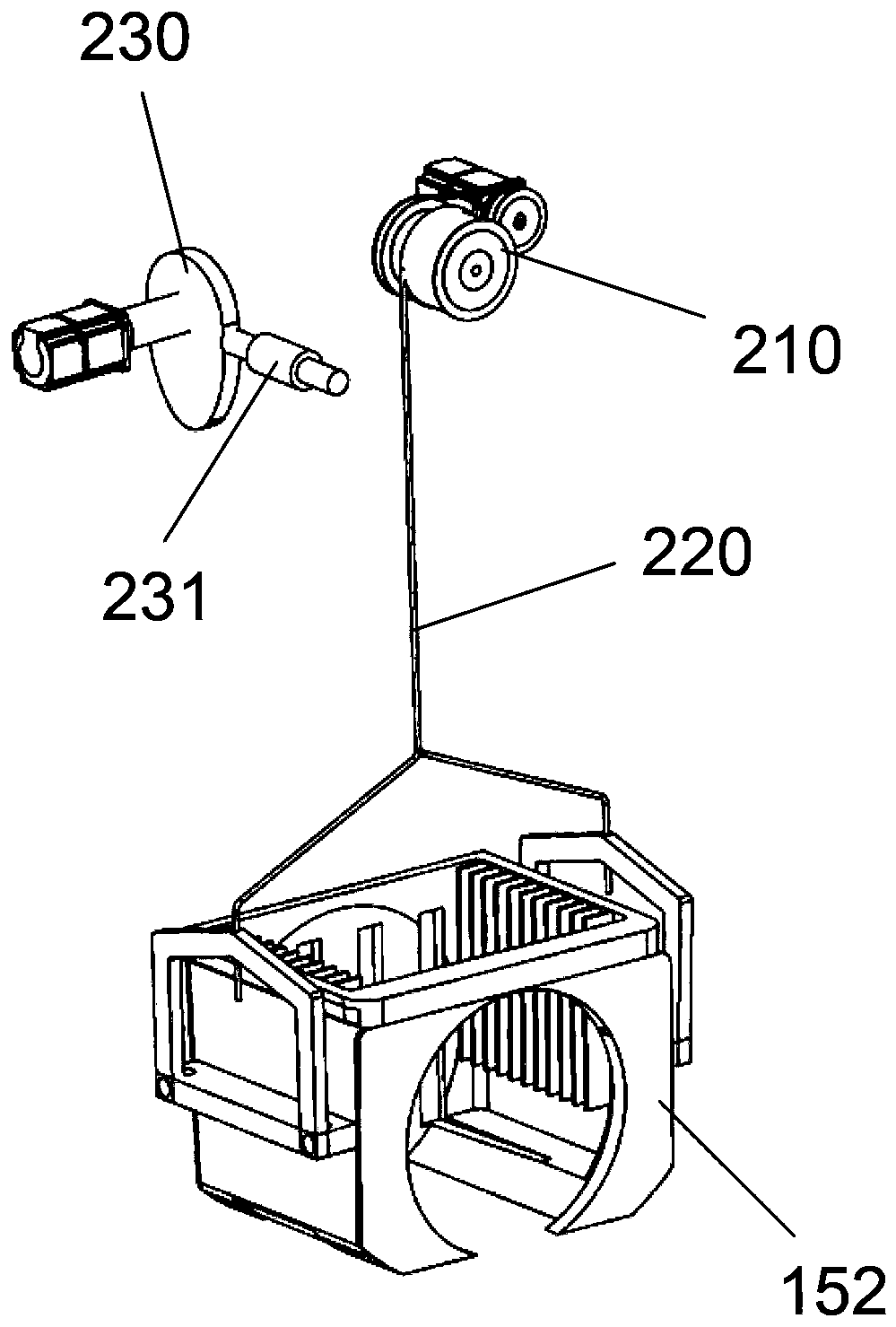

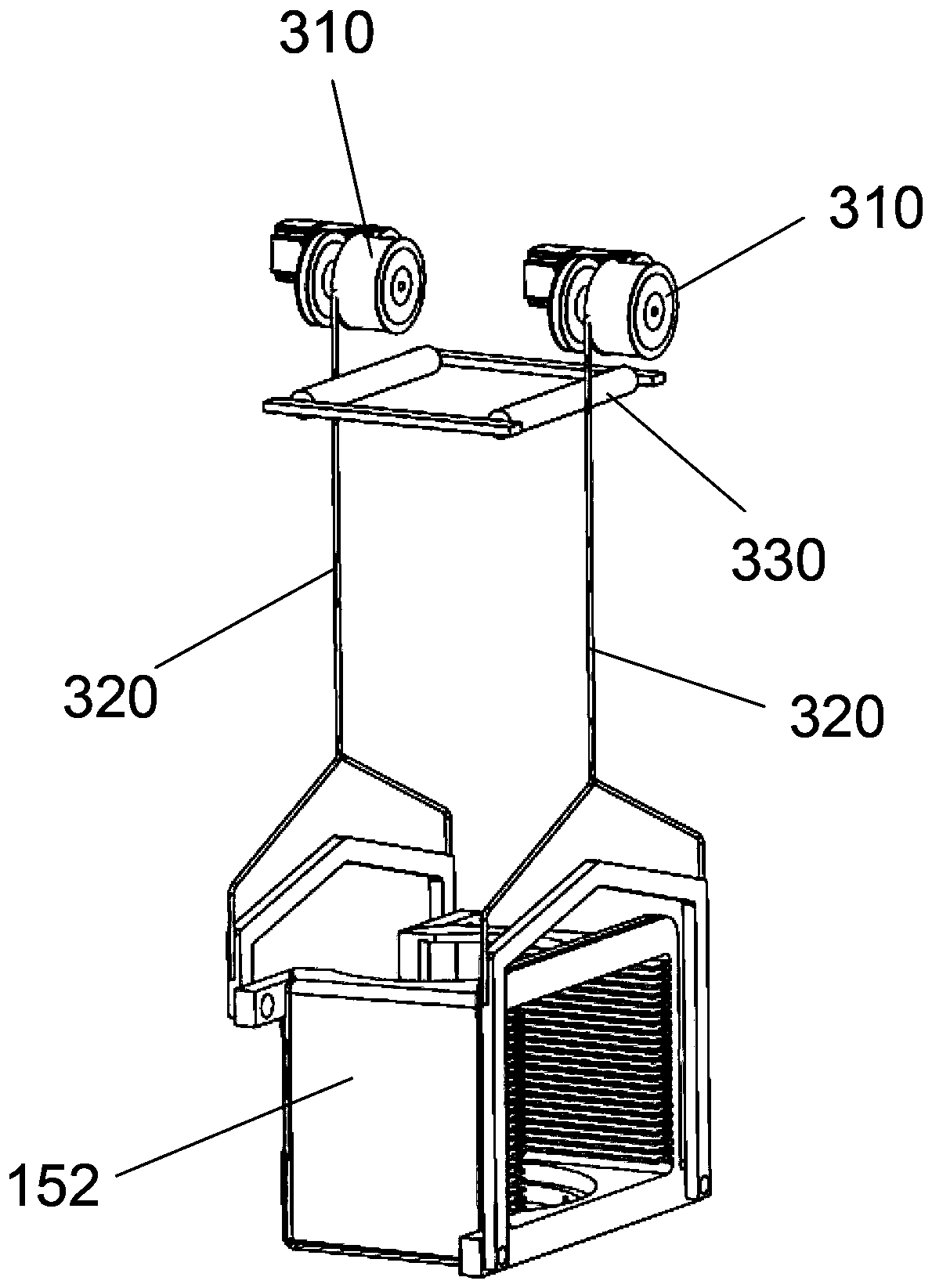

[0022] see figure 1 , which is a top view of the first embodiment of the substrate cleaning apparatus of the present invention. The substrate cleaning apparatus of the present invention includes a loading port 110 , a first robot 120 , a single-chip cleaning chamber 130 , a second robot 140 and a tank cleaning chamber 150 .

[0023] The load port 110 is used to load dry substrates. The first robot 120 is disposed between the load port 110 and the single-wafer cleaning chamber 130 for transferring dry substrates between the load port 110 and the single-wafer cleaning chamber 130, and the first robot 120 has one or more mechanical The arm 121 is used to transport the dry substrate. The single-wafer cleaning chamber 130 is used for cleaning and drying temporary storage substrates or single-wafer substrates. The single-wafer cleaning chamber 130 has a first valve 131 and a second valve 132 for transferring dry substrates and dry / wet substrates, respectively. . The first valve ...

Embodiment 2

[0033] see Figure 4 , which is a top view of the second embodiment of the substrate cleaning apparatus of the present invention. The substrate cleaning apparatus of the present invention includes a loading port 410 , a first robot 420 , a single-wafer cleaning chamber 430 , a second robot 440 , a tank cleaning chamber 450 and a buffer device 460 .

[0034] Load port 410 is used to load dry substrates. The first robot 420 is used for transferring dry substrates between the load port 410 , the single-wafer cleaning chamber 430 and the buffer device 460 , and the first robot 420 has one or more robot arms 421 for transferring the dry substrates. The single-wafer cleaning chamber 430 is used for cleaning and drying single-wafer substrates, and the single-wafer cleaning chamber 430 has a first valve 431 and a second valve 432 for transferring dry substrates and dry / wet substrates, respectively. The second robot 440 is used for transferring dry / wet substrates between the single-w...

Embodiment 3

[0041] see Figure 5 and Image 6 , is a schematic diagram of the third embodiment of the substrate cleaning apparatus of the present invention. The substrate cleaning apparatus of the present invention includes a load port 510 , a first robot 520 , a single wafer cleaning chamber 530 , a second robot 540 , a tank cleaning chamber 550 , a first buffer device 560 and a second buffer device 570 .

[0042] Load port 510 is used to load dry substrates. The first robot 520 is used for transferring dry substrates between the load port 510 , the first buffer device 560 and the second buffer device 570 , and the first robot 520 has one or more robot arms 521 for transferring dry substrates. There are at least two single-wafer cleaning chambers 530 located on the same side of the first buffer device 560 and the second buffer device 570 for cleaning and drying single-wafer substrates. Each single-wafer cleaning chamber 530 has a valve 531 For transporting dry / wet substrates. The sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com