Hydrothermal method for preparing Bi-doped ZnWO4 photocatalyst

A technology of photocatalyst and hydrothermal method, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. It can solve the problem of low utilization rate of visible light energy and achieve improved Photocatalytic performance, simplification of experimental conditions, effects of ensuring uniformity and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

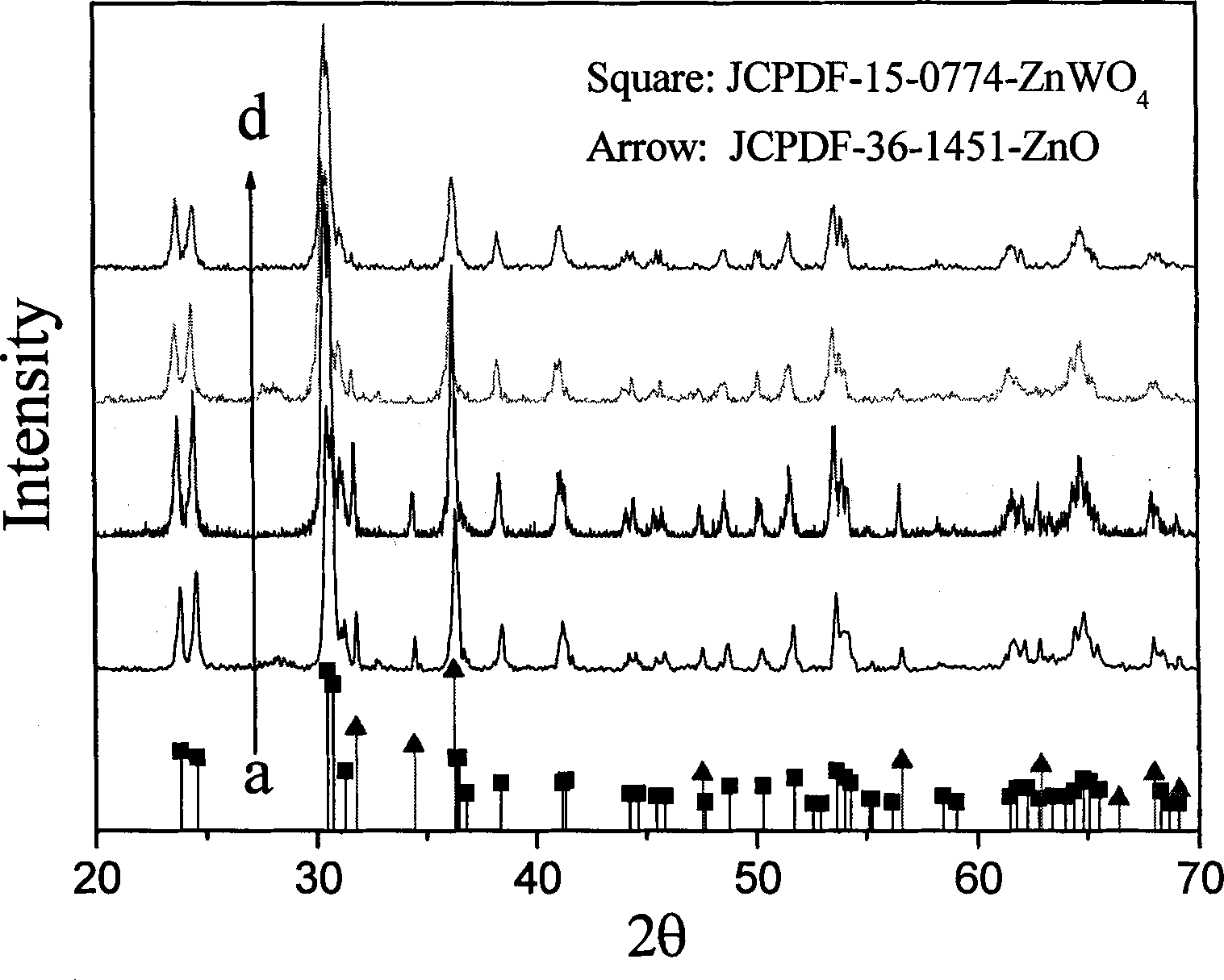

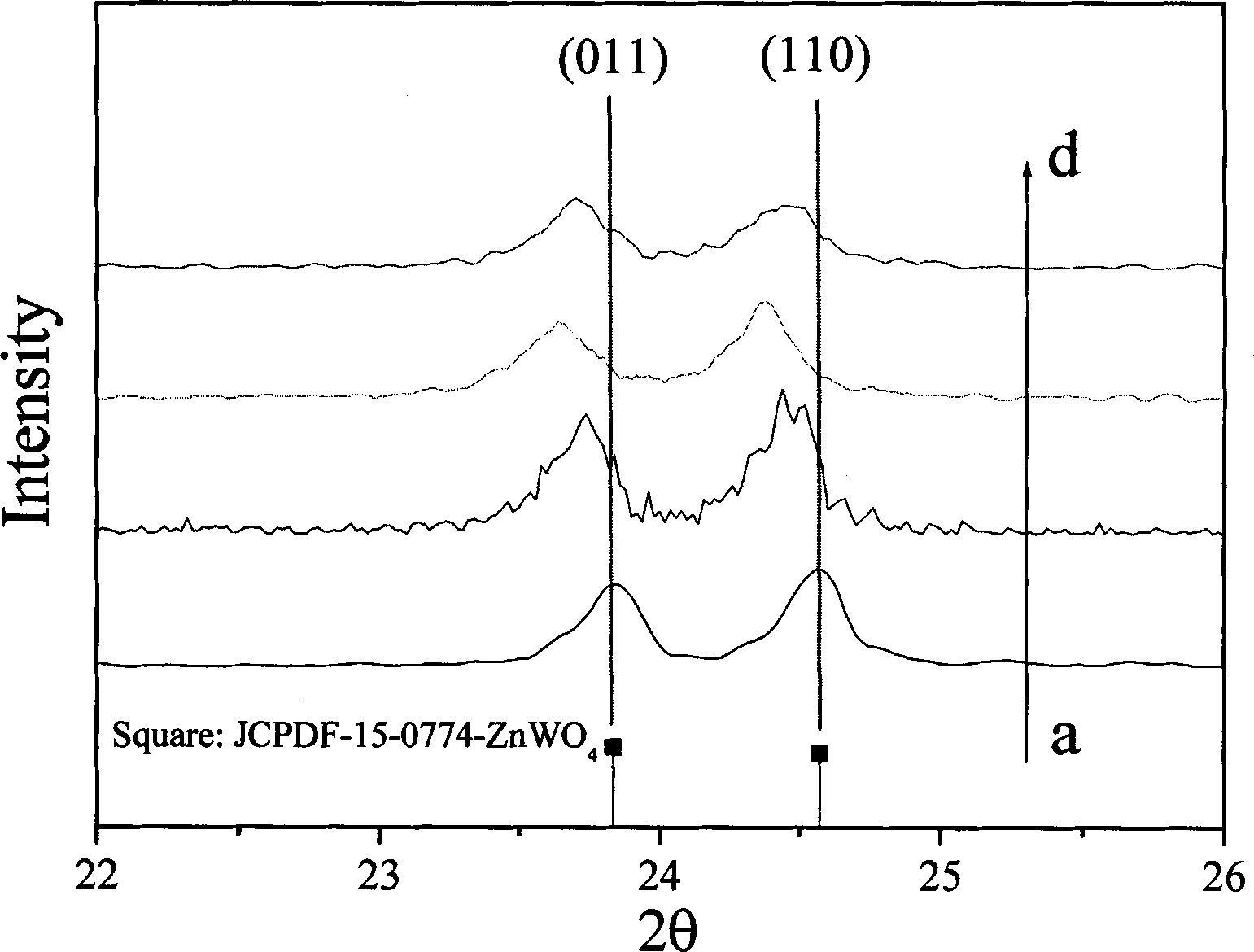

[0028] First, take 1 mmol of sodium tungstate dihydrate and zinc nitrate hexahydrate, add a certain amount of deionized water, and stir at room temperature. Adjust the pH value of the mixed solution to 8 with sodium hydroxide solution. Put it at room temperature and add 0.01% polyacrylamide (PAM, number average molecular weight 2.13×10 7 ), while magnetically stirring for 30 minutes, transfer to the reaction kettle, put the reaction kettle in the oven, keep it at 180°C for 48 hours, wait until it is cooled to room temperature, wash it with deionized water and absolute ethanol for 2-3 times, set Dry in the oven to get ZnWO 4 Powder, shown as needle-like by scanning electron microscope ( figure 1 ). Take bismuth nitrate pentahydrate and glucose (mass ratio 2:1) and dissolve them in ethylene glycol and water respectively to form A and B solutions. Mix the above AB solutions together, and then add a certain amount of needle-shaped ZnWO 4 Powder (based on bismuth nitrate pentahydra...

Embodiment 2

[0031] First, take 10 mmol of potassium tungstate and zinc sulfate heptahydrate, add a certain amount of deionized water, and stir at room temperature. Adjust the pH value of the mixed solution to 12 with potassium hydroxide solution. Put it at room temperature and add 0.05% polyacrylamide (PAM, number average molecular weight 2.13×10 7 ), while magnetically stirring for 120 minutes, transfer to the reactor, put the reactor into the oven, keep it at 150°C for 24 hours, after it cools to room temperature, wash it with deionized water and absolute ethanol for 2-3 times, oven Medium drying, get ZnWO 4 powder. As in Example 1, Suspension C was transferred to a reaction kettle at a reaction temperature of 150°C, and a reaction time of 24 hours. After cooling to room temperature, it was washed with ethanol and deionized water several times, and dried at 50°C for 24 hours to obtain needles. Bi-doped ZnWO 4 Photocatalyst such as Image 6 . The photocatalysis experiment was the same a...

Embodiment 3

[0033] First, take 5mmol of the total substance of the mixture of sodium tungstate dihydrate and potassium tungstate, and add a certain amount of deionization to the mixture composed of zinc nitrate hexahydrate, zinc sulfate heptahydrate, and zinc chloride. The total substance is 5mmol. Water, stir at room temperature. Adjust the pH value of the mixed solution to 10 with sodium hydroxide or potassium hydroxide solution. Put it at room temperature and add 0.03% polyacrylamide (PAM, number average molecular weight 2.13×10 7 ), while magnetically stirring for 100 minutes, transfer to the reactor, put the reactor into the oven, keep it at 160℃ for 36 hours, wait until it is cooled to room temperature, wash it with deionized water and absolute ethanol for 2-3 times, set Dry in the oven to get ZnWO 4 powder. As in Example 1, Suspension C was transferred to a reaction kettle at a reaction temperature of 140°C, and a reaction time of 20 hours. After cooling to room temperature, it was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com