A rocking plasma confinement device

A plasma and confinement device technology, which is applied in the field of plasma etching equipment reaction chamber cleaning device, can solve the problems of weak electric field, difficult cleaning of polymer 8, and weak chemical reaction, so as to increase the probability of reaction and stabilize the etching process , Improve the effect of cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

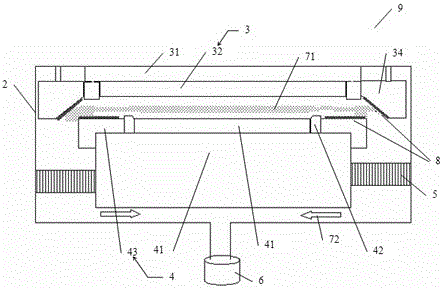

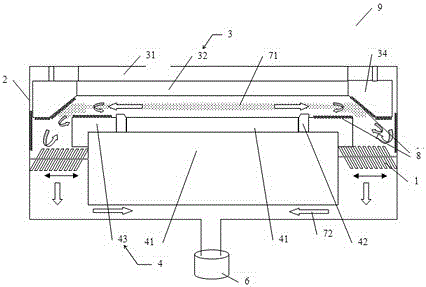

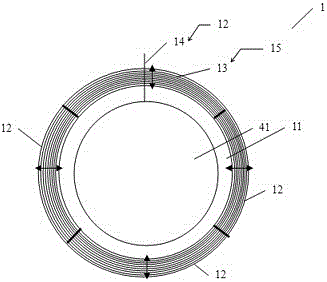

[0025] as attached figure 2 As shown, a plasma etching equipment, the reaction chamber 9 is provided with a chamber wall 2 covering the inner working space, the upper electrode assembly 3 and the lower electrode assembly 4 are arranged in the chamber wall 2, and the upper electrode assembly 3 is included in the The heater 31 on the inner wall of the top of the reaction chamber 9, the gas shower head 32, and the movable confinement ring 34 arranged around the gas shower head 32; the lower electrode assembly 4 is arranged below the upper electrode assembly 3, including an electrostatic chuck 41, which is arranged in sequence The focus ring 42 and cover ring 43 around the electrostatic chuck 41 and the lower electrode assembly 4 are connected to the radio frequency power supply of the plasma etching equipment; an e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap