Telescope rack control system

A control system and telescope technology, applied in the field of control and electronics, to ensure safe operation, good rigidity, and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

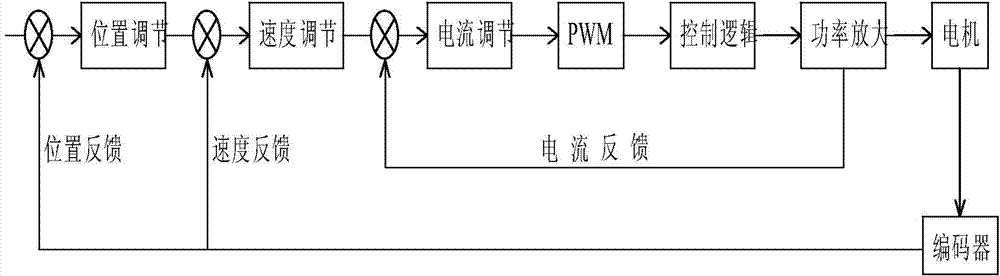

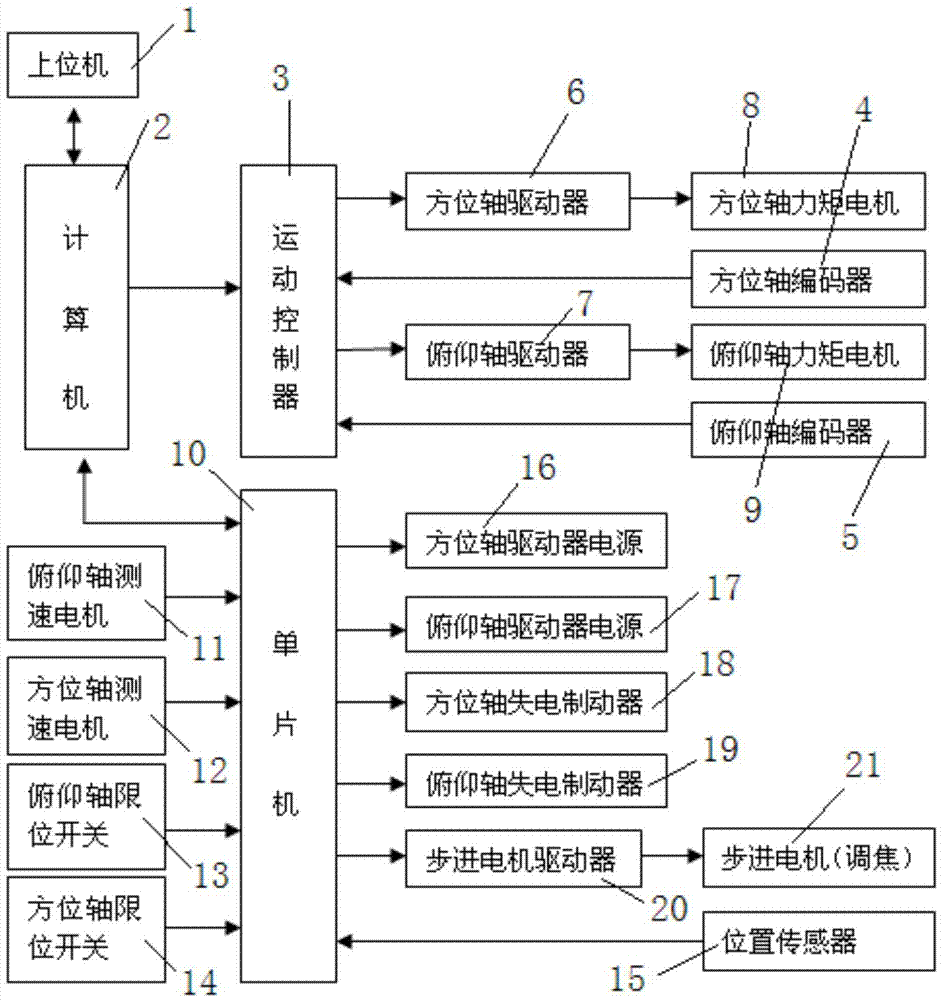

[0019] The principle block diagram of the rack control system is as follows: figure 1 As shown, a telescope rack control system includes a computer 2, a servo control system and a single-chip microcomputer control system, the servo control system includes a motion controller 3, and the signal input end of the motion controller 3 is connected to an azimuth axis encoder 4, a pitch axis Axis encoder 5, the signal output terminal of motion controller 3 is connected to azimuth axis driver 6 and pitch axis driver 7, and azimuth axis driver 6 and pitch axis driver 7 are connected to azimuth axis torque motor 8 and pitch axis torque motor 9 respectively; The control system includes a single-chip microcomputer 10, the signal input end of the single-chip microcomputer 10 is connected with a pitch axis speed measuring motor 11, an azimuth axis speed measuring motor 12, a pitch axis limit switch 13, an azimuth axis limit switch 14, a position sensor 15, and the signal output of the single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com