Electromagnetic ultrasonic transducer in multiphase structure and ultrasonic high-efficient excitation method

An electromagnetic ultrasonic, multi-phase technology, applied in the direction of ultrasonic/sonic/infrasonic wave generation, etc., can solve the problems of limited application, low energy conversion efficiency, discrete information of detected surface defects, etc., to achieve efficient excitation and unidirectional emission, The effect of increasing space density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

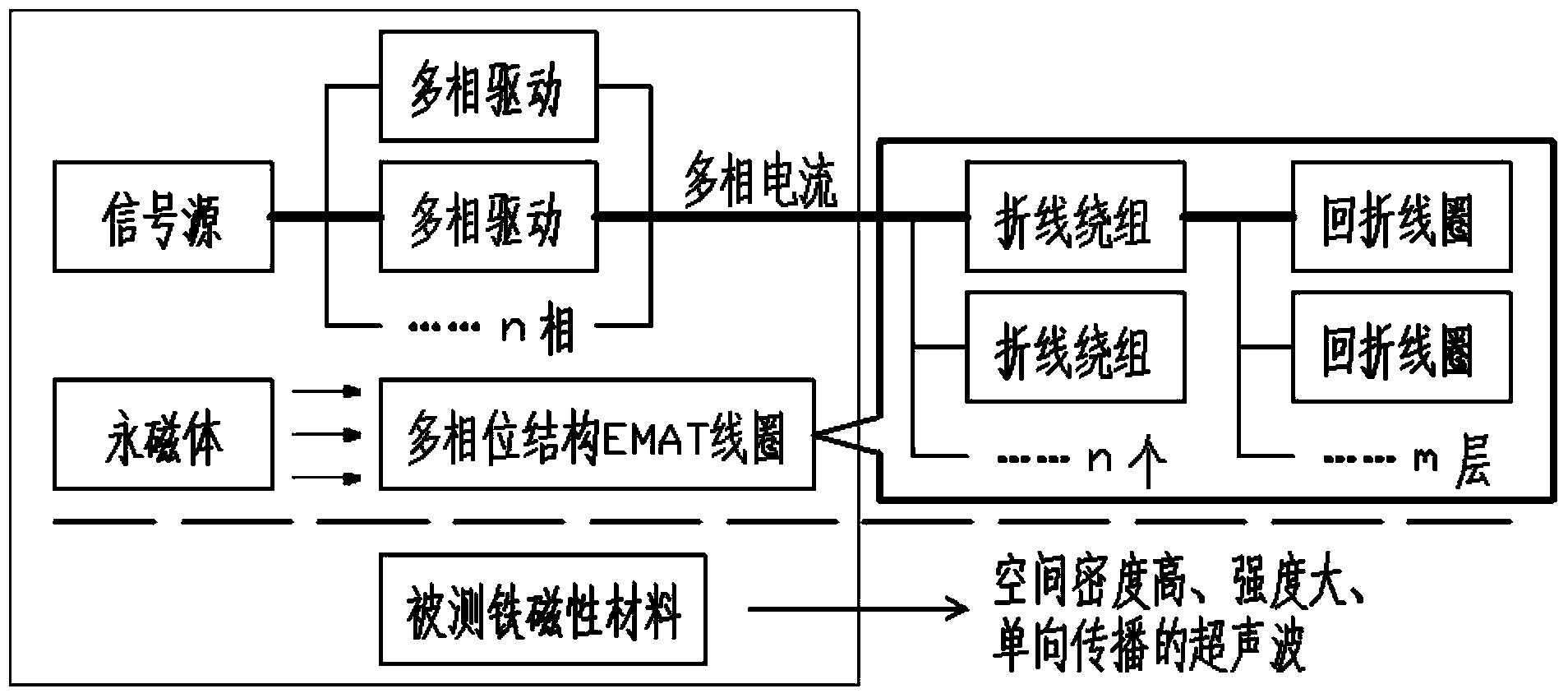

[0027] refer to Figure 1-4 , an electromagnetic ultrasonic transducer with a multi-phase structure, comprising: a permanent magnet 10, a multi-phase EMAT coil 11, a measured ferromagnetic material 12, a signal source, and a multi-phase drive circuit; the permanent magnet 10 is placed in the Above the measured ferromagnetic material 12, the measured ferromagnetic material 12 is magnetized to provide a bias magnetic field in the horizontal direction;

[0028] The multiphase EMAT coil is composed of n zigzag windings, n>1; in this embodiment, it is preferably 3 phases, that is, n=3; and placed on the surface of the ferromagnetic material to be tested to increase the space density of ultrasonic excitation ; The equidistant distance l between the folded wire windings is distributed on the plane of the EMAT coil;

[0029] The folded wire winding is composed of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com