Fe-Ga material based magnetostriction liquid-level sensor

A magnetostrictive liquid level and sensor technology, which is applied in the direction of buoy liquid level indicators, etc., can solve the problems of poor temperature characteristics, low magnetostriction coefficient, and low magnetic field sensitivity, and achieve good temperature characteristics, low cost, and overcome high The effect of high-frequency noise signal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings. This embodiment is only a specific description of the invention and is not considered as limiting the scope of protection.

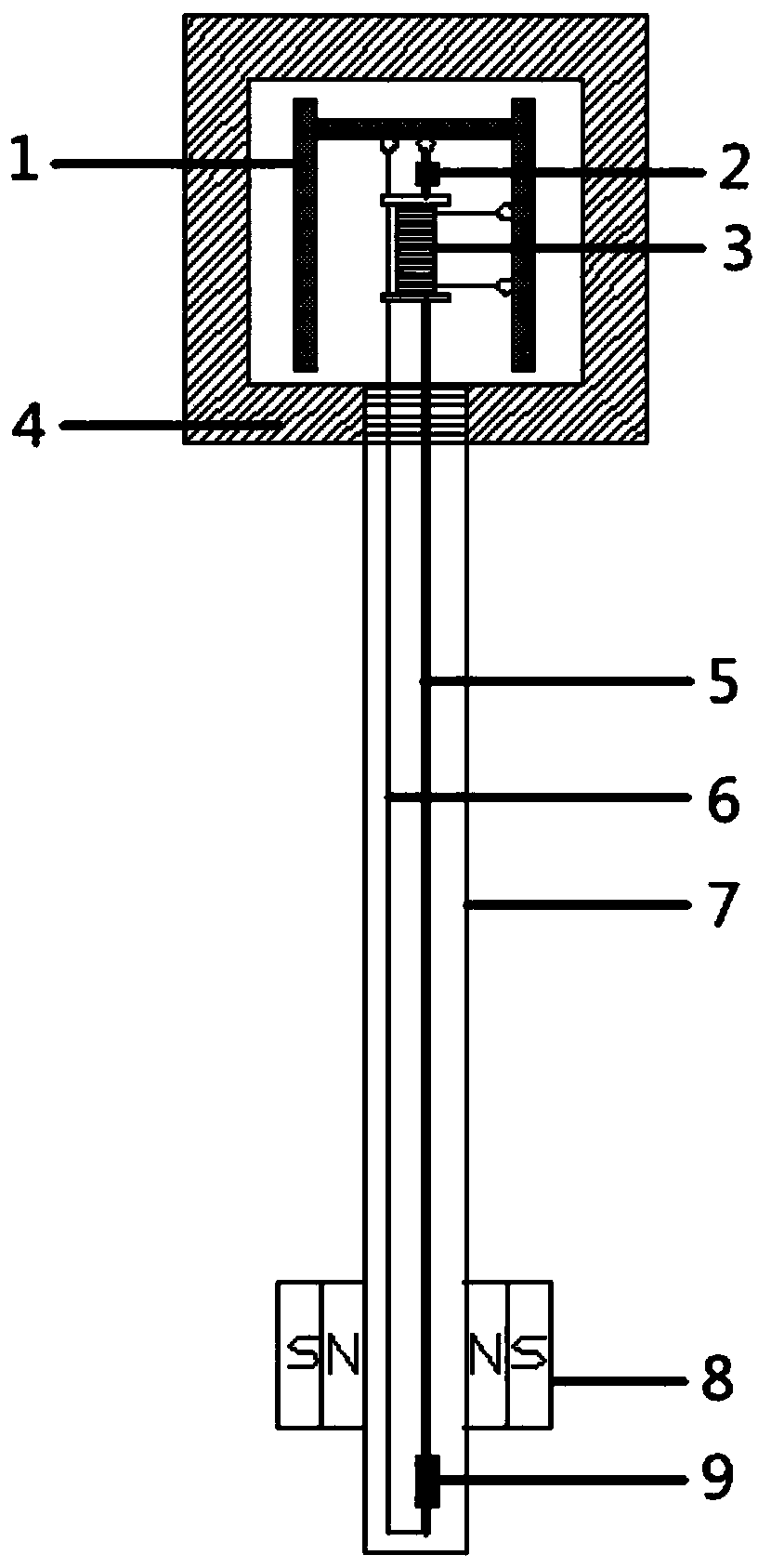

[0022] figure 1 It is a cross-sectional view of the structure of the magnetostrictive liquid level sensor.

[0023] The sensor consists of a sensor head 4, a measuring rod 7 and a float 8, wherein the upper part of the sensor is the sensor head 4, and the lower part of the sensor head 4 is connected to the measuring rod 7 through a threaded connection, and the movable float 8 is sleeved on the measuring rod 7. the lower part.

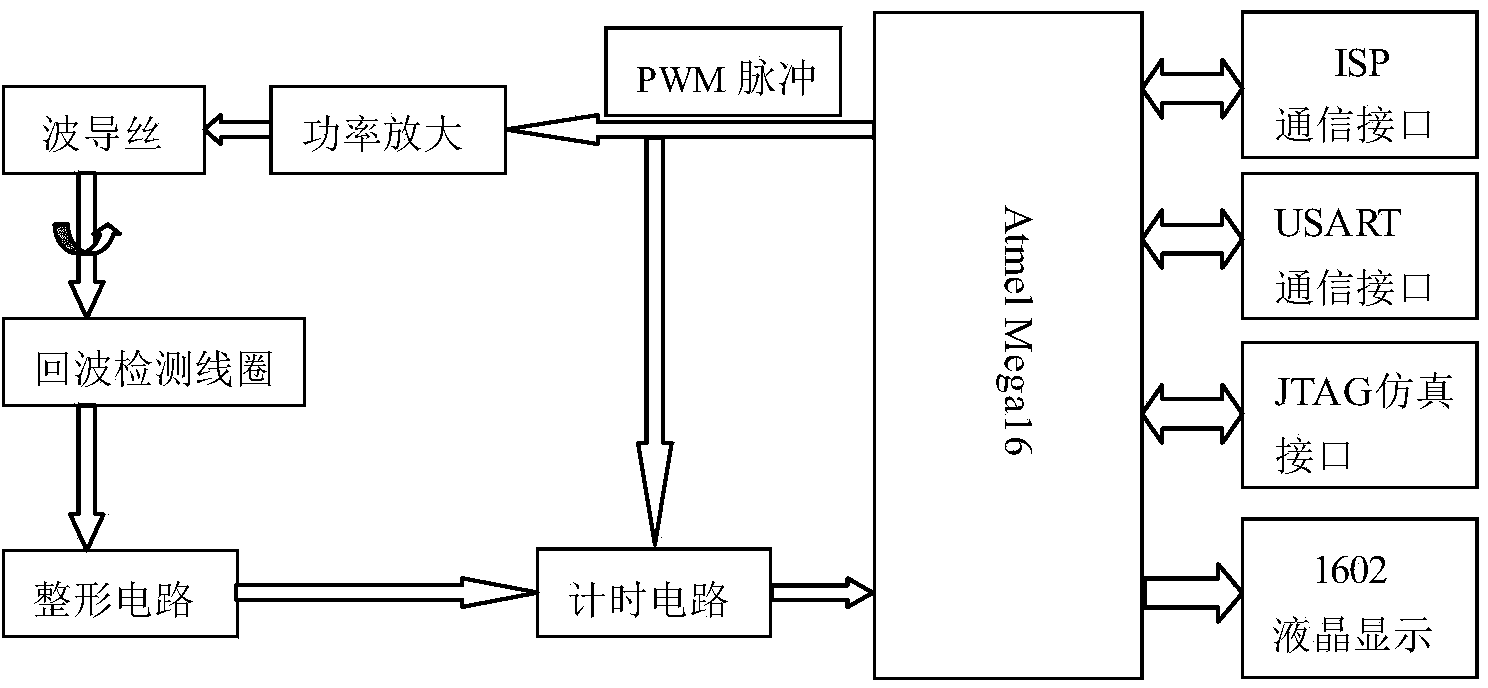

[0024] The sensor head 4 is a cylindrical structure, which includes a hardware circuit system 1, a detection device 3 and a front damping device 2; wherein the hardware circuit system 1 includes three parts: a power supply, a control system, a power amplification and a signal processing system, The three parts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com