Dealing with Design Changes and Smaller Sections of Floor Steel Beams Under Loading Conditions

A technology for design changes and processing methods, which is applied in building maintenance, construction, building construction, etc., can solve the problems of high labor intensity, high construction cost, and consumption of pipe materials, etc., to reduce labor intensity of workers, reduce construction costs, The effect of saving support material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

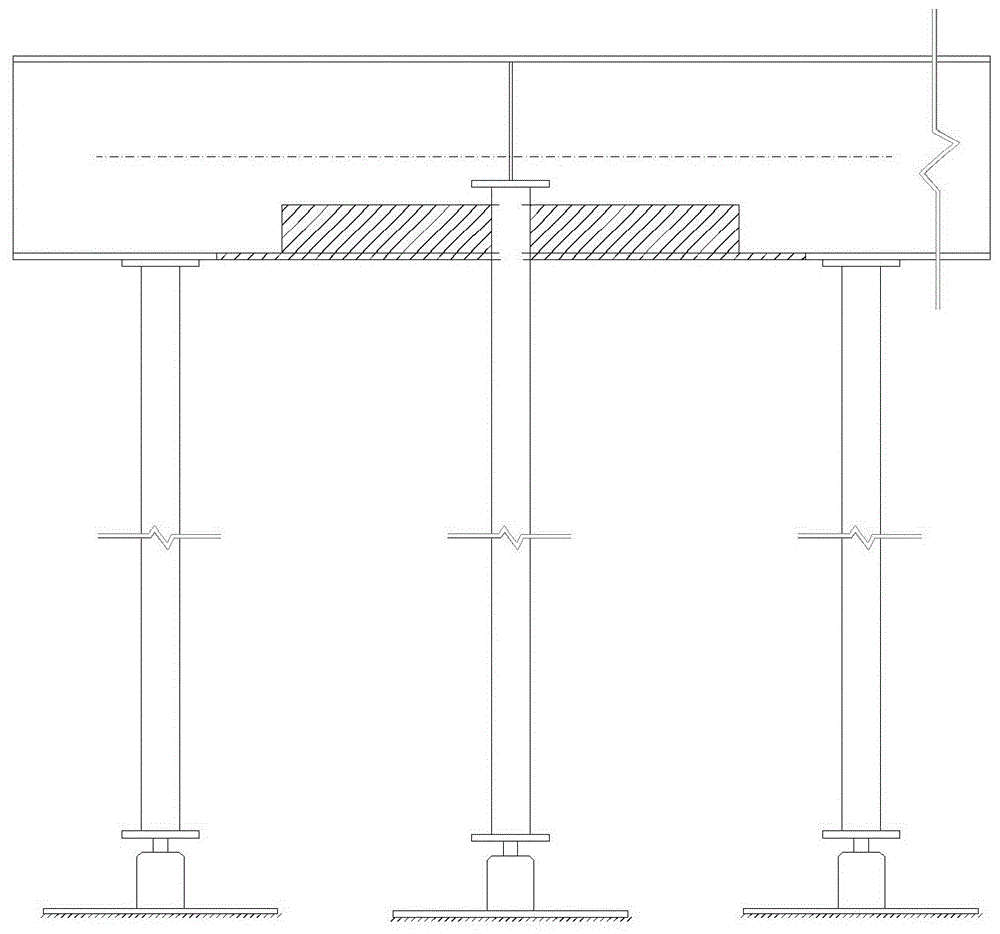

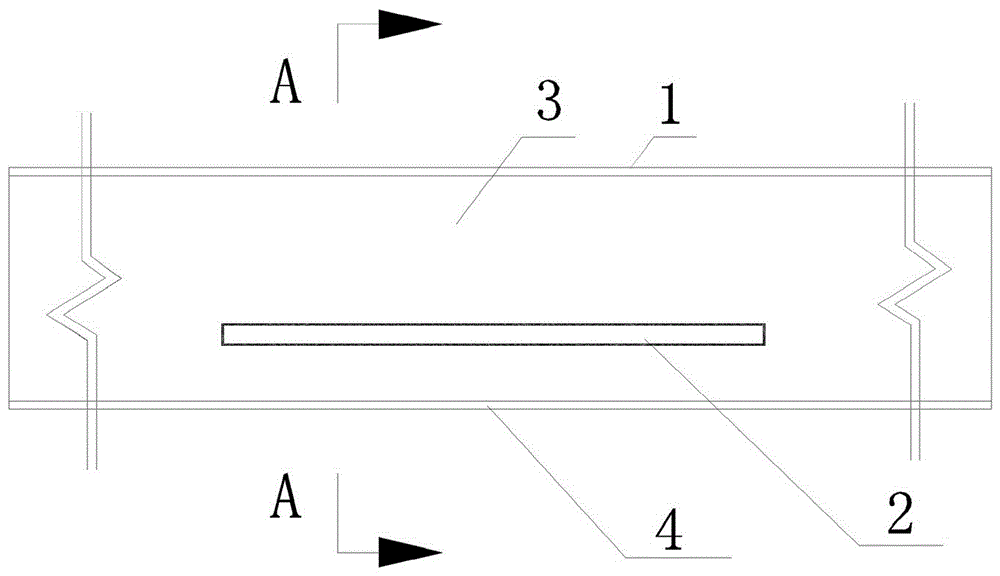

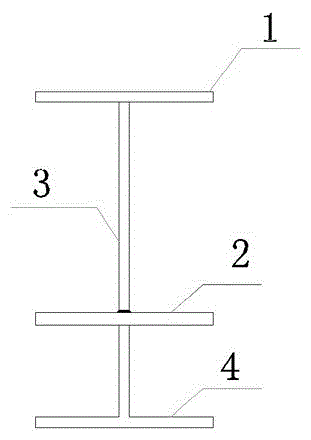

[0028] Referring to attached drawing 1, attached figure 2 Further description, under the loading situation of the present invention, the design change section of the floor steel girder is changed to a smaller processing method: a: According to the load bearing situation of the girder 1, the shear force calculation of the new lower wing plate 2 in the middle of the girder 1 is carried out, and the new position of the new lower wing plate 2 in the middle of the girder 1 is determined. The position of the lower wing plate 2 is changed; the shear force capacity of the girder 1 meets the requirements of the design specification after the opening of the cutout on the web plate 3;

[0029] b: According to the design change requirements, a cut is made in the middle of the web 3 where the new lower wing 2 is installed after the design change. Use a grinder to grind the cutout of the reserved web 3 to prepare for the installation of the new lower wing 2;

[0030] c: Weld the web 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com