Anti-seepage floor slab and anti-seepage construction method

A construction method and anti-leakage technology, which is applied to floors, pipes, building components, etc., can solve the problems that cannot meet the requirements of industrialized construction and waterproof safety, the waterproof layer and the pipe wall are easy to form cracks, and the construction process is cumbersome. Facilitate the industrialization of housing, save waterproof materials, and reduce the effect of on-site cooperation with construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

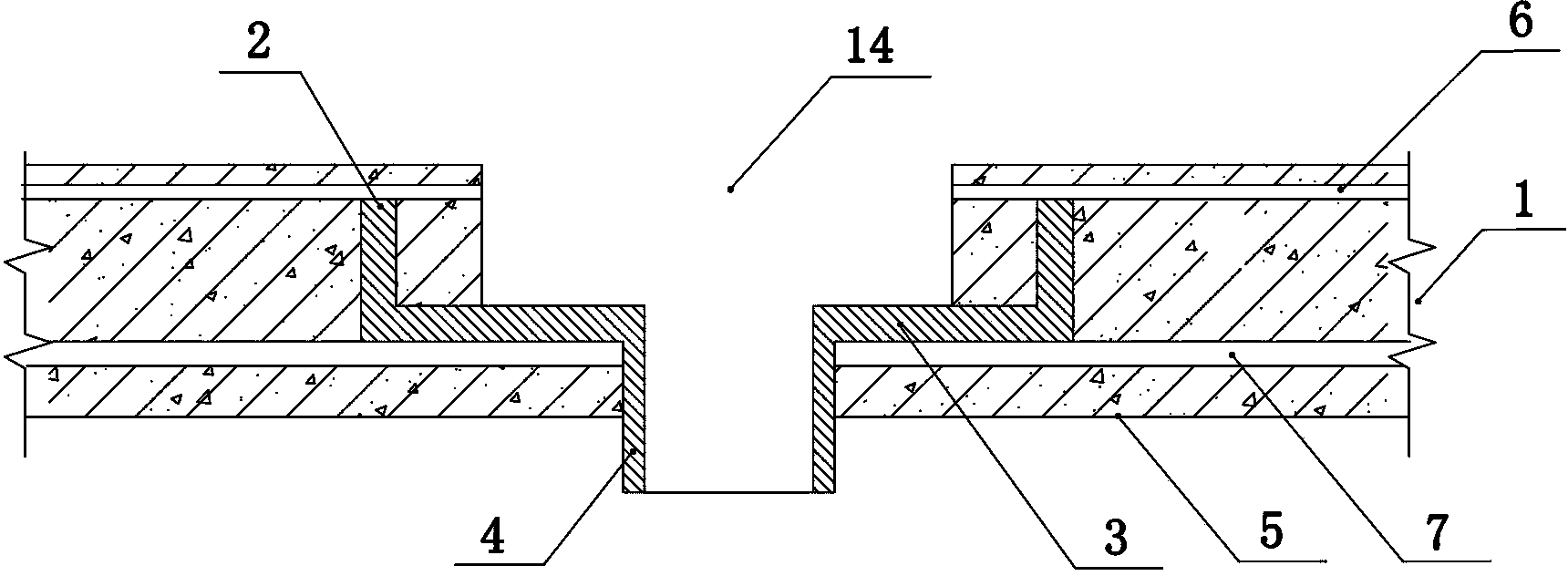

[0029] Such as figure 1 As shown, an anti-leakage floor, which includes a floor slab body 1 and a waterproof connector pre-embedded in the floor slab body 1, the waterproof connector includes an anti-seepage cylinder and a connection at the bottom of the anti-leakage cylinder Pipe 4, the top and side wall 2 of the anti-leakage cylinder are pre-embedded in the floor panel body 1, the lower end of the connecting pipe 4 protrudes downward from the lower surface of the floor panel body 1, and the waterproof connector and the floor panel body 1 form a funnel Shaped socket hole 14.

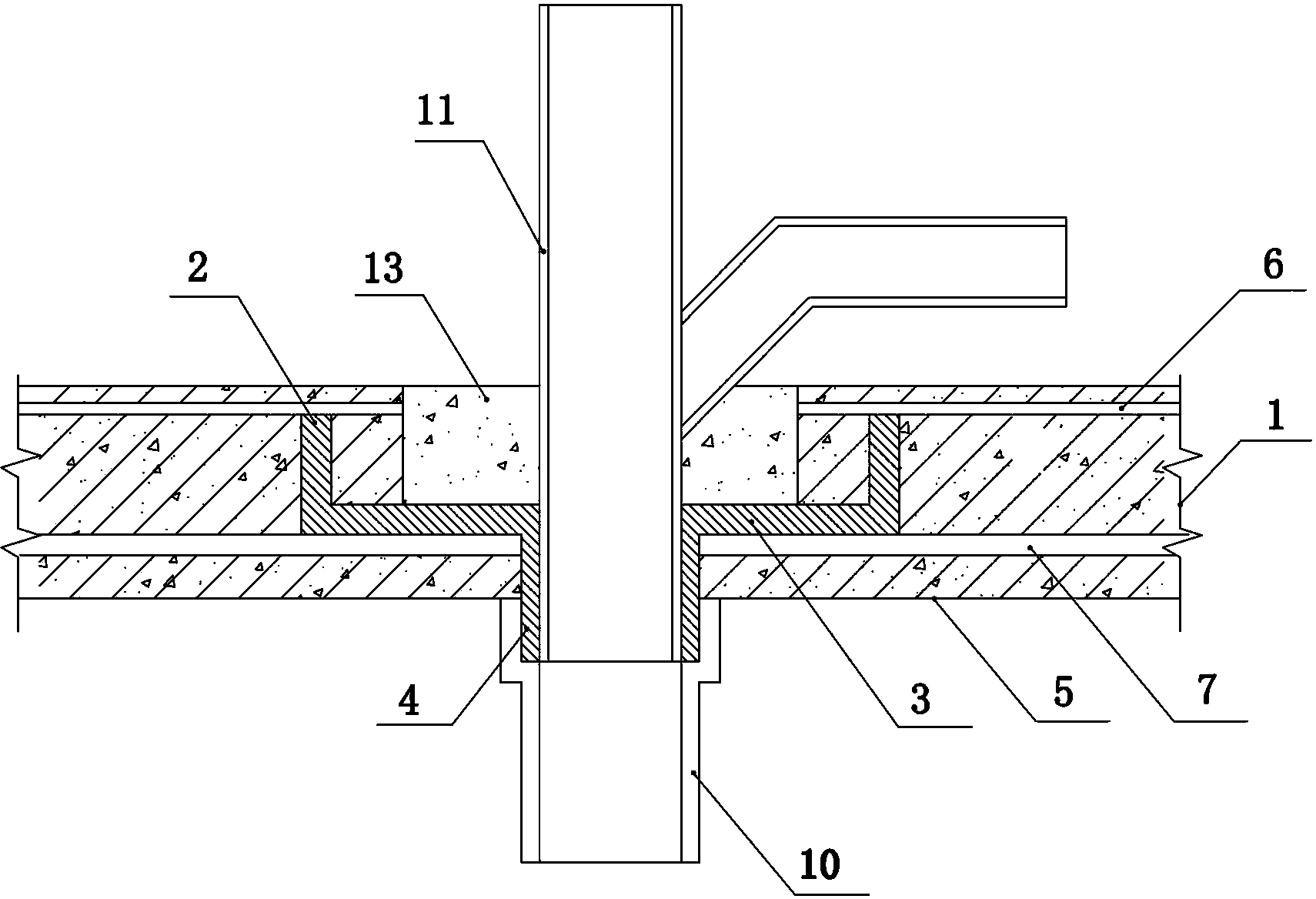

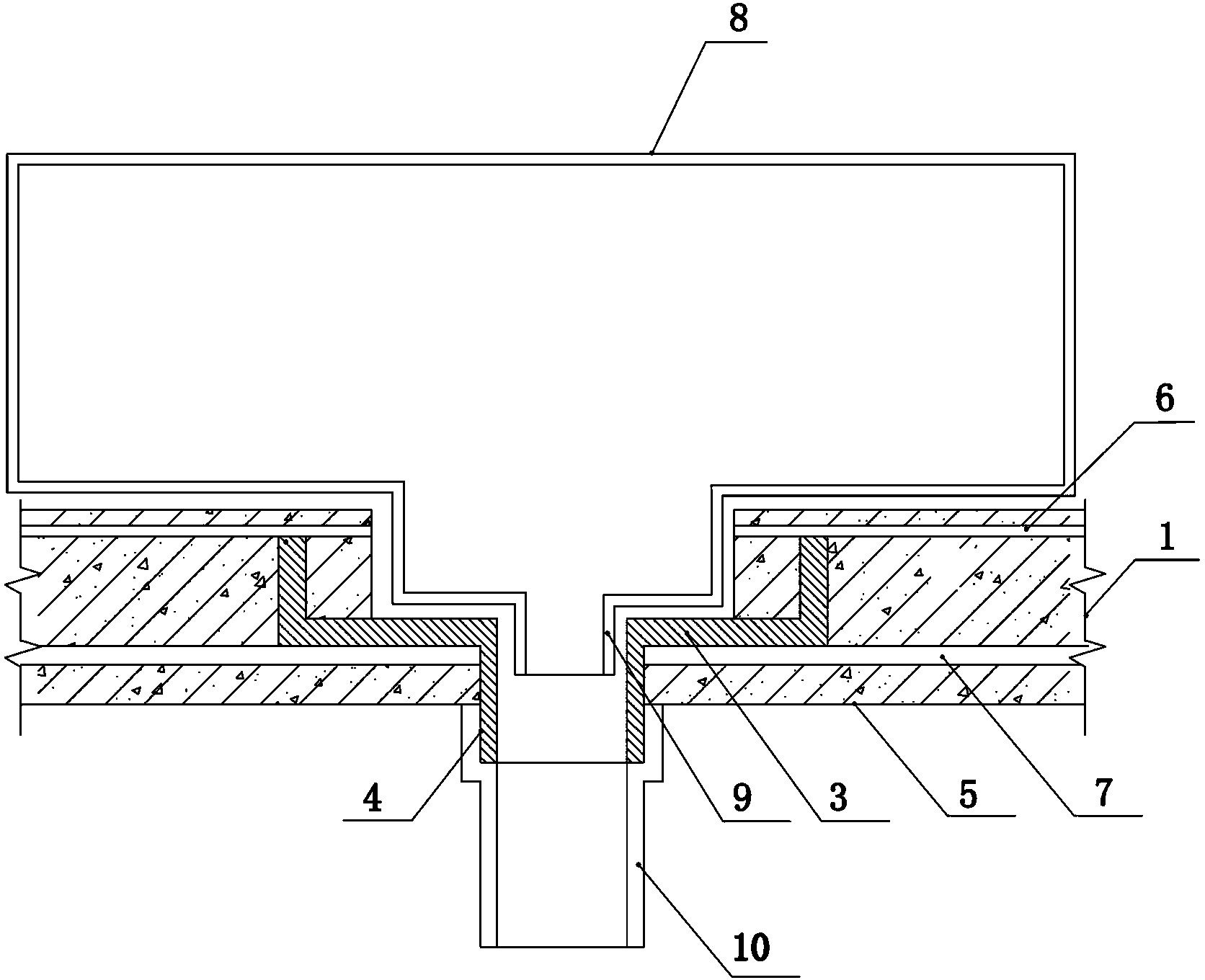

[0030] For the anti-seepage floor slab in this embodiment, when installing the drainage pipes on the same floor, as figure 2 As shown, the lower part of the three-way standpipe nipple 11 is inserted into the connecting pipe, and then the joint is caulked with co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com