Buoyancy tank type deepwater pile group bridge abutment construction platform and construction method thereof

A technology for construction platforms and working platforms, which is applied in bridges, sheet pile walls, bridge construction, etc. It can solve the problems of difficult installation of steel hanging boxes, waste of artificial materials, and large investment in equipment, so as to reduce equipment input and reduce construction costs. Difficulty, the effect of speeding up the progress of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

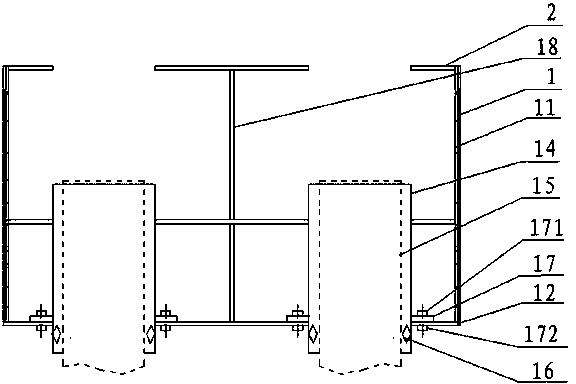

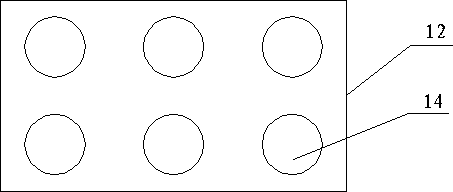

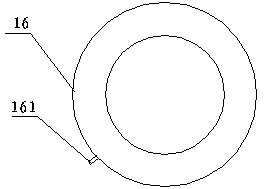

[0038] refer to Figure 1~Figure 3 , a buoyant box type deep water pile group abutment construction platform provided in this embodiment includes a buoyant box type construction platform 1, and the buoyant box type construction platform 1 is surrounded by a side enclosure steel mold 11 and a bottom surface enclosure steel mold 12, Dense water belts are provided between the joints of all enclosure steel forms; a working platform 2 is set up on the upper part of the floating box type construction platform 1, and there are platform reserved holes corresponding to all pile holes 13 on the working platform 2, and piling The pile body steel pipe 15 can pass through the reserved hole of the platform; the middle part of the floating box type construction platform 1 is provided with a bracket 18, which is used to connect and support the floating box type constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com