Insulating material for bus and preparation method thereof

A technology for insulating materials and busbars, applied in the field of insulating materials for busbars and its preparation, can solve problems such as low mechanical strength, uneven current distribution, and reduced current-carrying capacity, and achieve long service life, good dispersion, and reduced internal The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

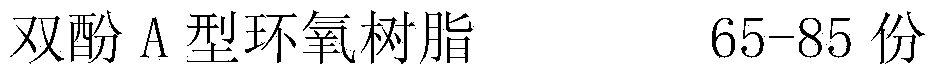

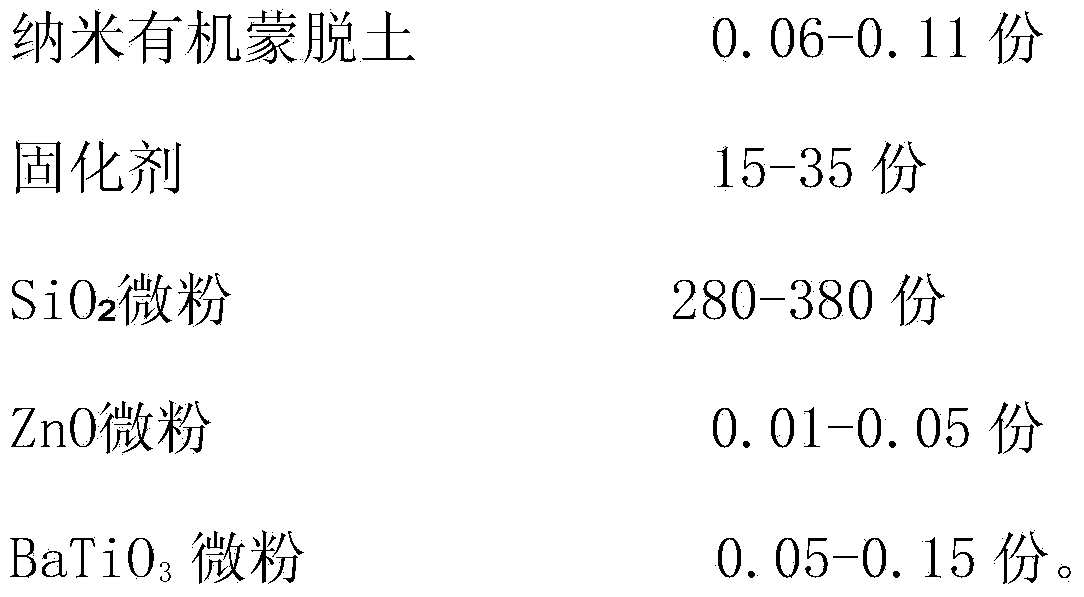

[0037] An insulating material for busbars, the composition of which is as follows in parts by weight:

[0038]

[0039] A preparation method for an insulating material for a busbar is as follows:

[0040] 1. Heating and melting the bisphenol A epoxy resin of 80 parts by weight, the heating temperature is 70-80°C, heating for 30 minutes;

[0041] 2. 0.03 parts by weight of nano-organic montmorillonite is vacuum-treated for 120 minutes at a temperature of 70-80°C;

[0042] 3. the bisphenol A type epoxy resin obtained in step 1, the nano-organic montmorillonite after the step 2 process, the SiO of 280 parts by weight 2 Micropowder, the ZnO micropowder of 0.01 weight part and 0.08 weight part BaTiO 3 Put the fine powder into a ball mill for ball milling and vacuum degassing for 6 hours, and disperse to obtain a primary mixture. The temperature of the ball mill is set at 70-80°C, the vacuum degree is 133Pa, and the rotation speed is 800 rpm;

[0043] 4. Heat and melt 20 parts...

example 2

[0050] An insulating material for busbars, the composition of which is as follows in parts by weight:

[0051]

[0052] A preparation method for an insulating material for a busbar is as follows:

[0053] 1. Heating and melting the bisphenol A epoxy resin of 75 parts by weight, the heating temperature is 70-80°C, heating for 30 minutes;

[0054] 2. Vacuum treatment of 0.05 parts by weight of nano-organic montmorillonite at 70-80°C for 120 minutes;

[0055] 3. the bisphenol A type epoxy resin that step 1 obtains, the nano-organic montmorillonite after the step 2 process, the SiO of 320 parts by weight 2 Micropowder, the ZnO micropowder of 0.01 weight part and 0.08 weight part BaTiO 3 Put the fine powder into a ball mill for ball milling and vacuum degassing for 6 hours, and disperse to obtain a primary mixture. The temperature of the ball mill is set at 70-80°C, the vacuum degree is 133Pa, and the rotation speed is 800 rpm;

[0056] 4. Heat and melt 25 parts by weight of di...

example 3

[0063] An insulating material for busbars, the composition of which is as follows in parts by weight:

[0064]

[0065]

[0066] A preparation method for an insulating material for a busbar is as follows:

[0067] 1. Heating and melting the bisphenol A epoxy resin of 85 parts by weight, the heating temperature is 70-80 ℃, heating for 30 minutes;

[0068] 2. 0.03 parts by weight of nano-organic montmorillonite is vacuum-treated for 120 minutes at a temperature of 70-80°C;

[0069] 3. the bisphenol A type epoxy resin that step 1 obtains, the nano-organic montmorillonite after the step 2 process, the SiO of 320 parts by weight 2 Micropowder, the ZnO micropowder of 0.01 weight part and 0.08 weight part BaTiO 3 Put the fine powder into a ball mill for ball milling and vacuum degassing for 6 hours, and disperse to obtain a primary mixture. The temperature of the ball mill is set at 70-80°C, the vacuum degree is 133Pa, and the rotation speed is 800 rpm;

[0070] 4. Heat and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com