Butyl rubber composite gel oil absorption material and preparation method thereof

A butyl rubber and composite gel technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of long processing time, low recycling rate, and difficult recycling, and achieve fast forming, large adsorption capacity, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A butyl rubber composite gel oil-absorbing material, the preparation method of which is as follows:

[0028] (1) Crush butyl rubber, weigh 5g, dissolve it in 100mL chloroform and let it stand for a period of time. When the rubber becomes transparent, that is, the butyl rubber has been fully dissolved to obtain a rubber solution;

[0029] (2) In the rubber solution, 0.5g of accelerator octylphenol formaldehyde resin and 0.01g of p-benzoquinone dioxime were dispersed ultrasonically, and then 0.2mL of crosslinking agent disulfide dichloride was added with a pipette. The mixture was divided into petri dishes, covered and reacted at ambient temperature for 12 hours;

[0030] (3) After the reaction is completed, the obtained composite gel material is alternately washed with toluene and methanol, at least twice each; then dried in a fume hood at room temperature to obtain the butyl rubber composite gel oil-absorbing material.

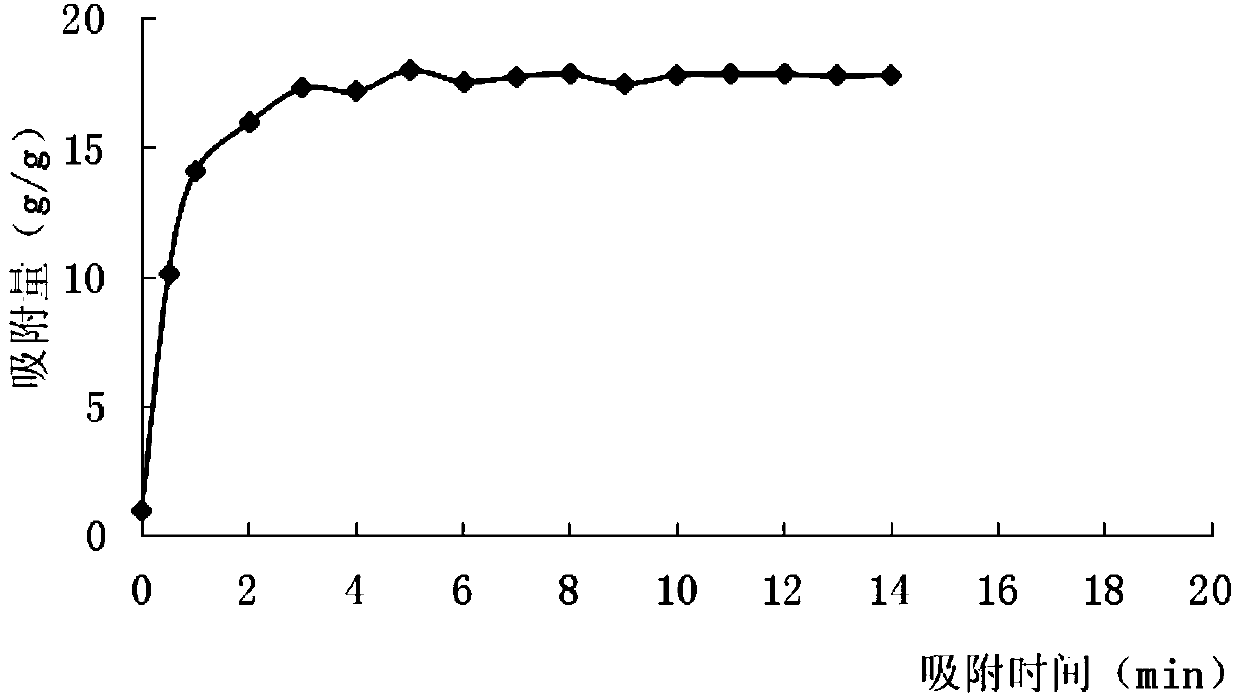

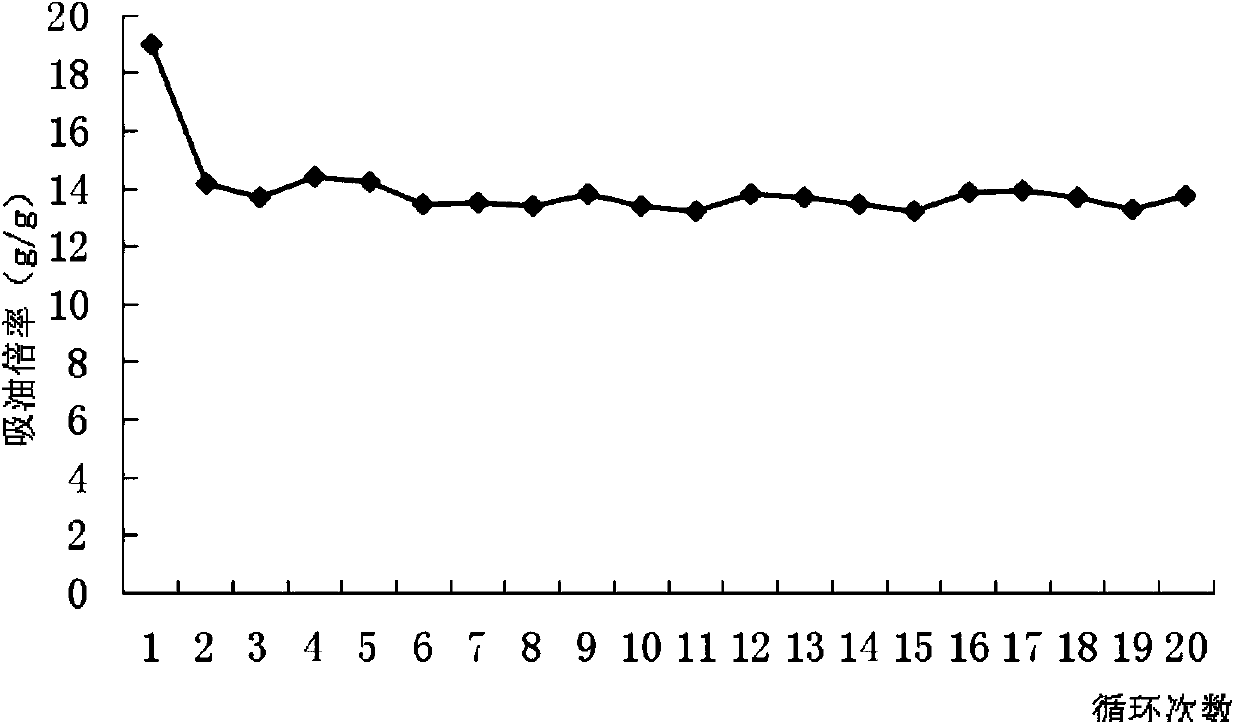

[0031] The above-mentioned fully dried oil-absor...

Embodiment 2

[0040] A butyl rubber composite gel oil-absorbing material, the preparation method of which is as follows:

[0041] (1) Crush butyl rubber, weigh 5g, dissolve it in 50mL chloroform and let it stand for a period of time. When the rubber becomes transparent, that is, the butyl rubber has been fully dissolved to obtain a rubber solution;

[0042] (2) Add 0.3g of accelerator octylphenol formaldehyde resin and 0.005g of p-benzoquinone dioxime to the rubber solution, ultrasonically disperse them, and then add 0.2mL of crosslinking agent disulfide dichloride with a pipette, The mixture was divided into petri dishes, covered and reacted for 10 hours;

[0043] (3) After the reaction is completed, the obtained composite gel material is alternately washed with toluene and methanol, at least twice each; then dried in a fume hood at room temperature to obtain the butyl rubber composite gel oil-absorbing material.

[0044] The oil-absorbing material obtained in this example has a water abs...

Embodiment 3

[0046] A butyl rubber composite gel oil-absorbing material, its preparation method is as follows:

[0047] (1) Crush butyl rubber, weigh 5g, dissolve it in 150mL chloroform and let it stand for a period of time. When the rubber becomes transparent, that is, the butyl rubber has been fully dissolved to obtain a rubber solution;

[0048] (2) Add 0.7g accelerator octylphenol formaldehyde resin and 0.02g p-benzoquinone dioxime to the rubber solution, ultrasonically disperse them, then add 0.5mL crosslinking agent disulfide dichloride with a pipette, The mixed solution is divided into petri dishes, covered and reacted at ambient temperature for 15 hours;

[0049] (3) After the reaction is completed, the obtained composite gel material is alternately washed with toluene and methanol, at least twice each; then dried in a fume hood at room temperature to obtain the butyl rubber composite gel oil-absorbing material.

[0050] image 3 The SEM image of the obtained butyl rubber composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com