Supermatant discharge system and sludge condensation method

A technology of discharge system and sludge tank, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of large sludge volume, high infrastructure investment, high production and operation cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

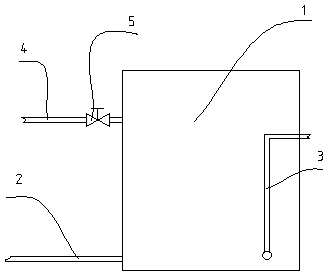

[0010] A sludge tank supernatant discharge system, it comprises a sludge tank 1, the bottom of the sludge tank is provided with a mud inlet pipe 2, the top is provided with a drain pipe 4; it also includes a sludge discharge device 3, the The sludge discharge equipment includes a sludge discharge pipe, and the inlet of the sludge discharge pipe is located at the bottom of the sludge tank 1 .

[0011] The drain pipe 4 is provided with a control valve 5, and the control valve 5 can be a manual or electric valve.

[0012] In the sludge pond supernatant liquid discharge system described in claim 1, the sludge in the previous sludge treatment equipment enters the sludge pond 1 through the mud inlet pipe 2, and when the sludge settles to the bottom of the sludge pond 1, the upper When the supernatant is in the upper part, open the control valve 5 on the drain pipe 4, discharge the supernatant through the drain pipe 4 on the upper part of the sludge tank 1, and then disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com