Device for concentrating and digesting sludge and generating power synchronously

A technology for digesting sludge and sludge, applied in biological sludge treatment, biochemical fuel cells, etc., can solve problems such as increased costs, complicated treatment process, and water not being effectively recycled, so as to improve power generation performance and economical The effect of reasonable treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

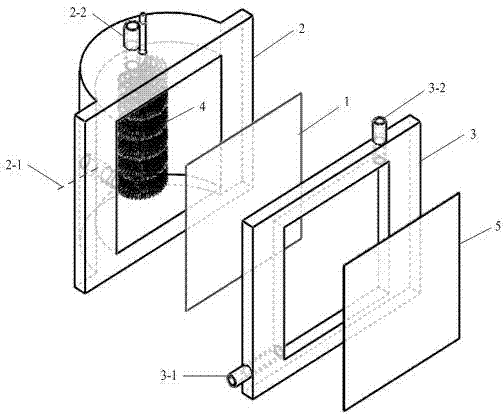

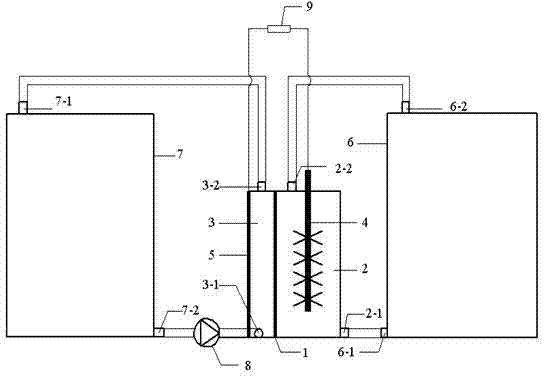

[0017] Embodiment 1: the forward osmosis-microbial fuel cell structure described in the embodiment of the present invention is as figure 1 As shown, it includes a FO membrane 1, an anode chamber 2, a cathode chamber 3, an anode electrode 4, and an air cathode 5. Such as figure 2 As shown, the FO membrane 1 divides the anode chamber 2 and the cathode chamber 3 of the microbial fuel cell. The anode chamber 2 is provided with a mud inlet 2-1 and a vent 2-2, the mud inlet can be arranged on the side wall of the anode chamber 2 near the bottom, the vent can be arranged on the top of the anode chamber 2, and the cathode chamber 3 is provided with a second A water inlet 3-1 and a second water outlet 3-2, the first water inlet 3-1 can be arranged on the side wall of the cathode chamber 3 near the bottom, and the second water outlet 3-2 is arranged on the top of the cathode chamber 3 to ensure the first The water inlet 3-1 and the second water outlet 3-2 are located at the farthest...

Embodiment 2

[0022]Embodiment 2: with the forward osmosis-microbial fuel cell described in embodiment 1, take the sludge of the primary sedimentation tank of a certain urban sewage treatment plant as fuel, its MLSS is 15.4~16.0 g / L, and MLVSS is 10.3~10.71 g / L, TCOD is 11.3~11.4 g / L, SCOD is 10.3~45.7 g / L,; the draw solution is 1.0 mol / L (NH 4 ) 2 HPO 4 solution. After running for 30 days, the output voltage of FO-MFC (load 470 Ω) is 478~498 mV, and the output power is 1.24~1.34 W / m 3 The TCOD, MLSS, and MLVSS digestion rates of digested sludge in the anode chamber were 31.4%, 35.0%, and 56.1%, respectively, and the MLVSS / MLSS value also decreased from 0.67 to 0.43; the diluted draw solution met the agricultural irrigation water standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com