Automatic feeder for label laser marking

A technology of laser marking and automatic loading and unloading, which is applied in the field of laser marking machines, can solve problems such as the inability to realize automatic control of feeding and marking, and achieve the effects of reducing personnel costs, improving competitiveness, and reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

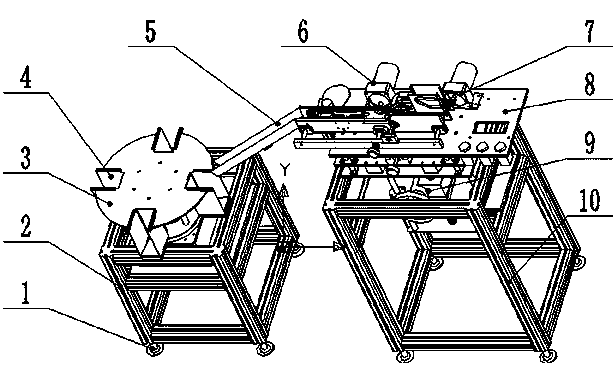

[0023] Label laser marking automatic loading and unloading machine, including a hopper for placing labels, a conveyor belt for conveying labels, and a device for receiving labels.

[0024] The automatic coding machine is mainly powered by motor 1 and motor 2. The hopper is used to place the signs to be coded. The self-aligning rings 1 and 2 can adjust the height of shafts 3 and 4, and the height of shafts 3 and 4 can be adjusted according to the thickness of the card. , control the gap between the friction wheel 3 and the bottom plate, and the gap between the friction wheel 4 and the friction wheel 5, to ensure that only one card can be passed at a time. When starting, the motor 1 is manually controlled to rotate, and the motor 1 drives the shaft 1, shaft 2, and shaft 3 to rotate through the synchronous belt 1. The other ends of the shafts 1, 2, and 3 are respectively installed with friction wheels 1, 2, 3 and shafts 1, 2 , 3 rotate synchronously, the upper horizontal tangent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com