Pneumatic tire

A technology of pneumatic tires and tires, applied in special tires, tire parts, tire treads/tread patterns, etc., can solve the problems of radio noise, hindering the release of static electricity to the road, and high resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052]In order to specifically show the structure and effects of the present invention, the following evaluations were performed on the following examples.

[0053] (1) Conduction performance (resistance value)

[0054] A specified load was applied to the tire mounted on the rim, and a voltage (500 V) was applied from the shaft supporting the rim to the metal plate grounded on the tire to measure the resistance value.

[0055] (2) Rubber hardness

[0056] The rubber composition was vulcanized at 150° C. for 30 minutes, and the rubber hardness of the vulcanized rubber at 23° C. was measured in accordance with JIS K6253.

[0057] (3) Rolling resistance

[0058] Rolling resistance was measured and evaluated by a rolling resistance tester. The result of Comparative Example 1 was evaluated as 100, and the larger the numerical value, the better the rolling resistance.

[0059] (4) Uniformity

[0060] According to the test method stipulated in JISD4233, LFV (lateral force variat...

Embodiment 1

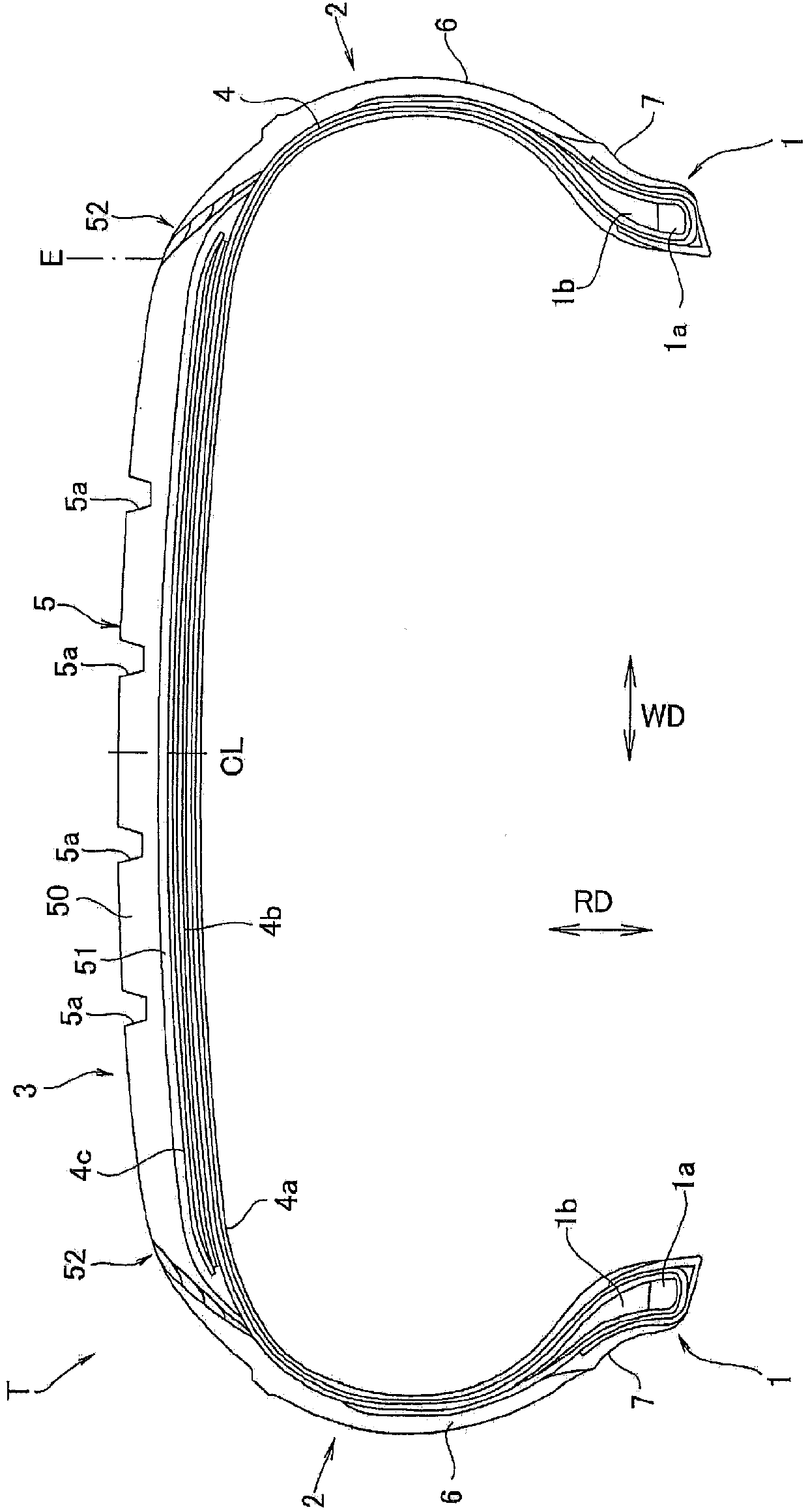

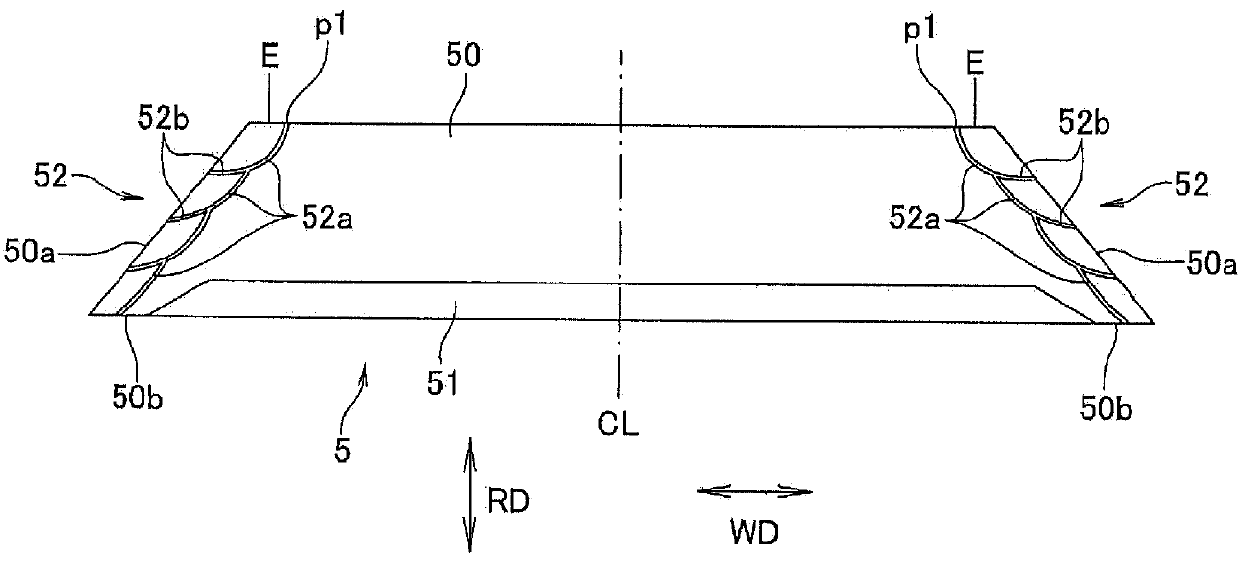

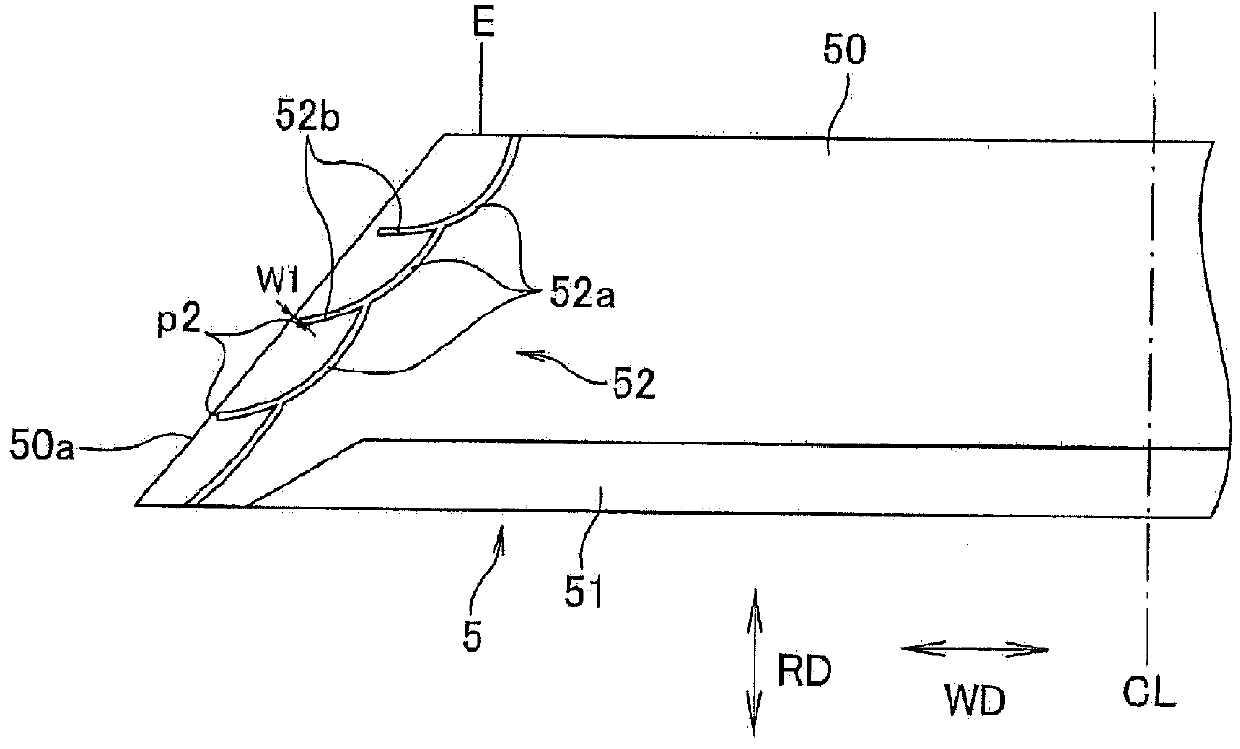

[0070] In the tire of Comparative Example 1, the conductive portion 52 was provided inside the both side wall portions of the crown portion 50 . The rubber hardness of the conductive portion 52 is set to be lower than the rubber hardness of the crown portion 50 . Other than that, it is the same as the tire of Comparative Example 1.

Embodiment 2

[0072] The conductive portion 52 is provided only on the vehicle body inner side end portion among the paired side end portions located on both sides in the tire width direction WD of the crown portion 50 . Other than that, it is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com