A method for manufacturing an integrated structure of a microwave and millimeter wave module with a thermal expansion coefficient

A technology of thermal expansion coefficient and manufacturing method, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of MMIC chip cracking, hidden quality problems, module failure, etc., and achieve the effect of reducing contact potential difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

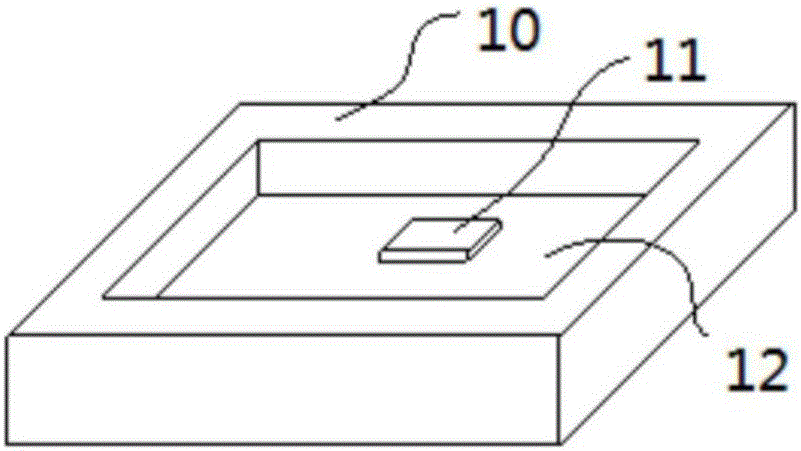

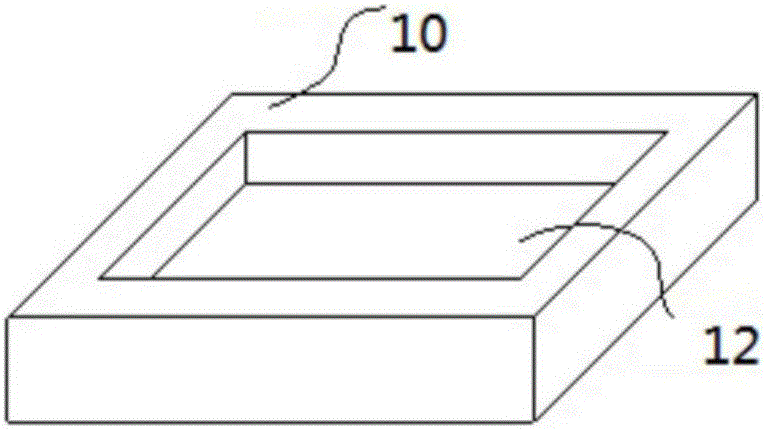

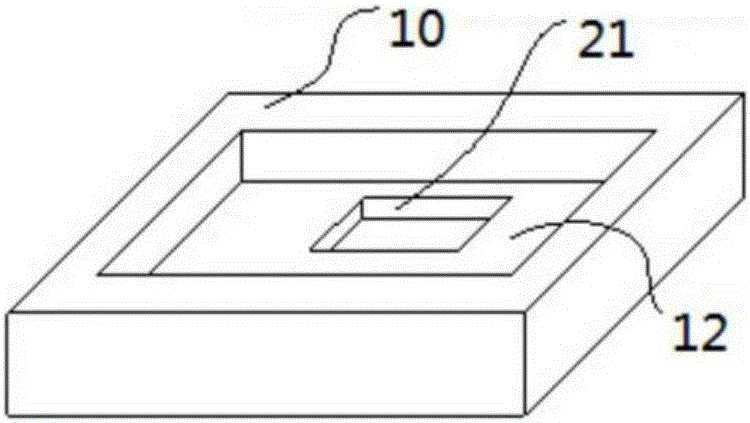

[0033] In the design scheme of this patent, the method of adding a buffer sheet is adopted, and a transition layer is added between the MMIC chip and the aluminum alloy shielding cavity. The thermal expansion coefficient of the buffer sheet is between the MMIC chip and the aluminum alloy, but closer to the MMIC chip. In such a structure, the stress caused by the mismatch of thermal expansion coefficients is mainly concentrated at the interface between the aluminum alloy shielding cavity and the buffer sheet. Due to the good thermal expansion coefficient matching between the buffer sheet and the MMIC chip, almost There is no stress, which can greatly improve the reliability of the entire integrated structure.

[0034] The manufacturing process of the integrated structure is: the production of the shielding cavity, the processing of the integrated groove of the buffer sheet, the processing of the buffer sheet, the partial gold plating of the integrated groove of the buffer sheet,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com