Full-aluminizing high-refractive-index glass microbead as well as production process thereof

A technology of glass microbeads and high refractive index, which is applied in the direction of optical components, optics, instruments, etc., can solve the problems such as the reduction of the retroreflection coefficient, achieve the effect of improving the retroreflection coefficient, good reflection effect, and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

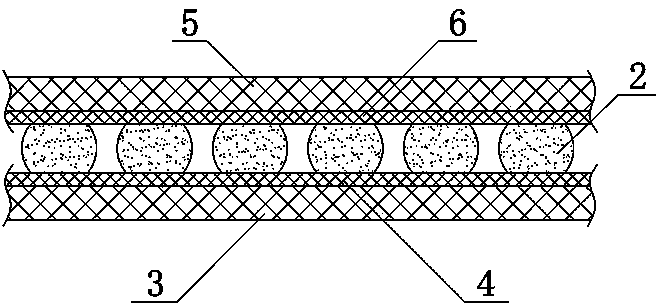

[0029] Such as Figure 6 As shown, a fully aluminized high-refractive index glass bead includes a glass bead body 1 and an aluminized layer 2, and the aluminized layer 2 completely covers the outer surface of the glass bead body 1.

[0030] The refractive index of the glass microsphere body 1 is 1.90.

[0031] The thickness of described aluminized layer 2 is

[0032] A production process of fully aluminized high refractive index glass beads comprises the following steps:

[0033] According to the requirements, the glass microbead body 1 is screened, and the glass microspheres with a particle size of 115 μm and a maximum particle size difference of 15 μm are ensured that the glass microbead body 1 that meets the aforementioned requirements accounts for more than 85% of the total share;

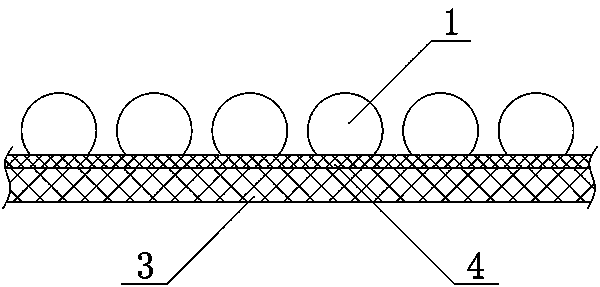

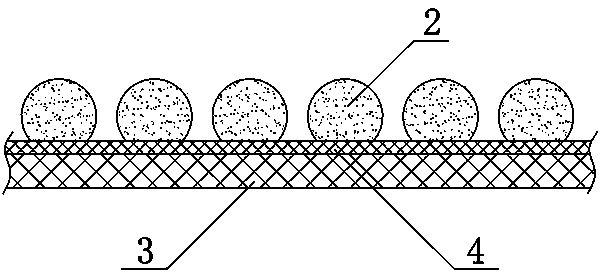

[0034] S1, planting beads: such as figure 1 As shown, coat the bead-planting resin layer A4 on one side of the substrate A3, dry it, and adhere the glass microsphere body 1 obtained in ste...

Embodiment 2

[0041] Such as Figure 6 As shown, a fully aluminized high-refractive index glass bead includes a glass bead body 1 and an aluminized layer 2, and the aluminized layer 2 completely covers the outer surface of the glass bead body 1.

[0042] The refractive index of the glass microsphere body 1 is 2.01.

[0043] The thickness of described aluminized layer 2 is

[0044] A production process of fully aluminized high refractive index glass beads comprises the following steps:

[0045] Screen the glass microbead body 1 according to the requirements, the glass microspheres with a particle size of 60 μm and a maximum particle size difference of 10 μm, and ensure that the glass microbead body 1 that meets the aforementioned requirements accounts for more than 85% of the total share.

[0046] S1, planting beads: such as figure 1 As shown, coat the bead-planting resin layer A4 on one side of the substrate A3, dry it, and adhere the glass microsphere body 1 obtained in step 1 to the ...

Embodiment 3

[0053] Such as Figure 6 As shown, a fully aluminized high-refractive index glass bead includes a glass bead body 1 and an aluminized layer 2, and the aluminized layer 2 completely covers the outer surface of the glass bead body 1.

[0054] The refractive index of the glass microsphere body 1 is 1.91.

[0055] The thickness of described aluminized layer 2 is

[0056] A production process of fully aluminized high refractive index glass beads comprises the following steps:

[0057] According to the requirements, the glass microbead body 1 is screened, and the glass microspheres with a particle size of 55 μm and a maximum particle size difference of 12 μm are ensured that the glass microbead body 1 meeting the aforementioned requirements accounts for more than 85% of the total share.

[0058] S1, planting beads: such as figure 1 As shown, coat the bead-planting resin layer A4 on one side of the substrate A3, dry it, and adhere the glass microsphere body 1 obtained in step 1 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com