Adjustable rotary kiln heat collection system and heat energy collection method

A heat energy collection, rotary kiln technology, applied in the direction of rotary drum furnace, waste heat treatment, lighting and heating equipment, etc., can solve the problems of low water cooling cycle efficiency, accelerated kiln body corrosion, poor heat exchange, etc., to achieve convenient disassembly and installation, The effect of improving energy efficiency and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

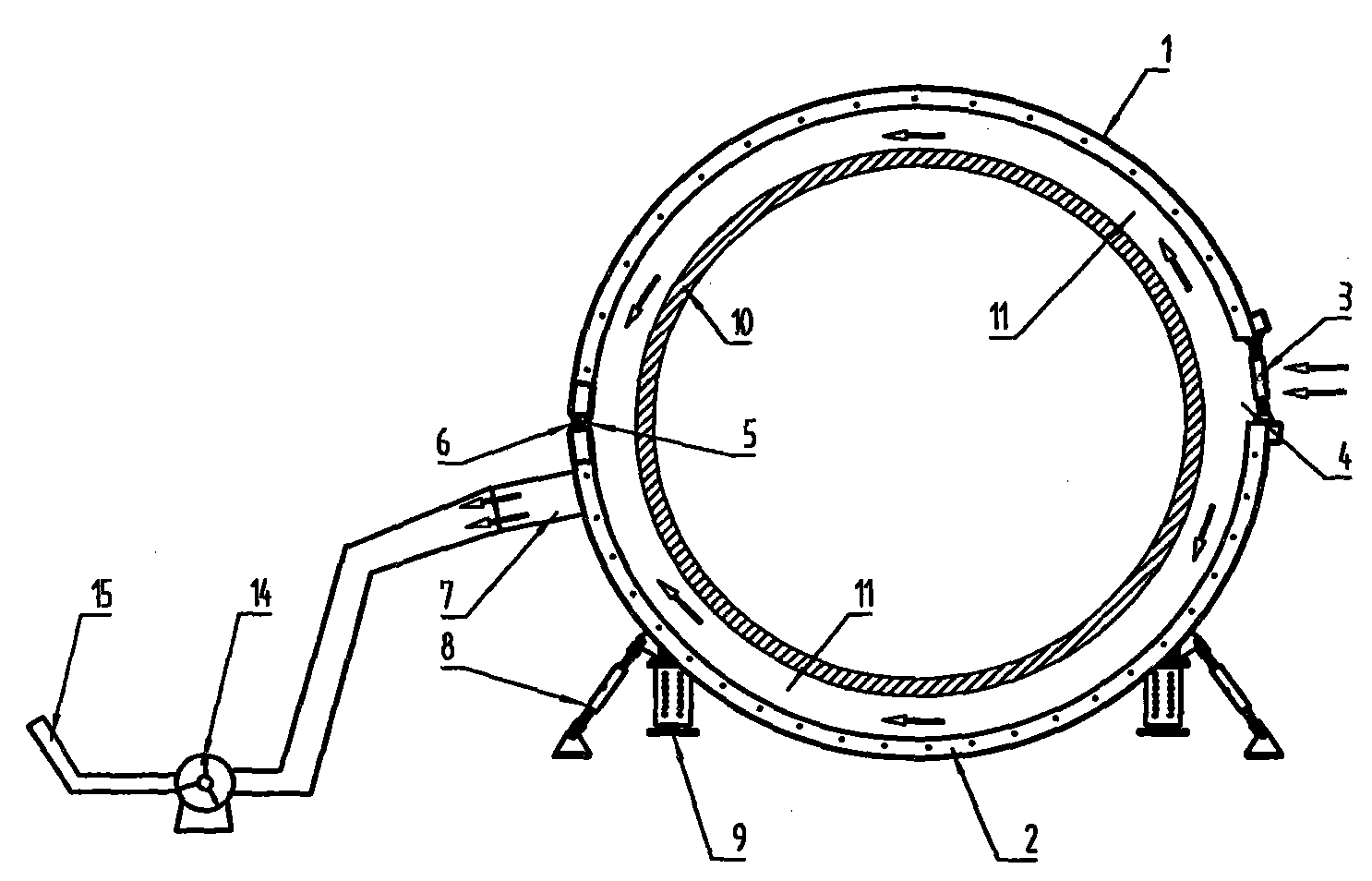

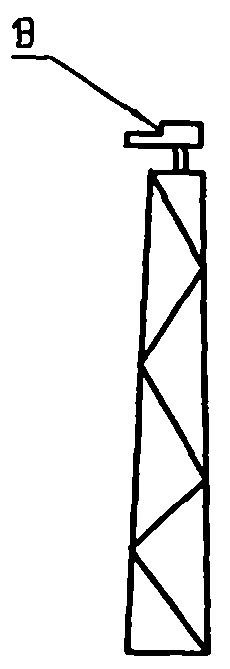

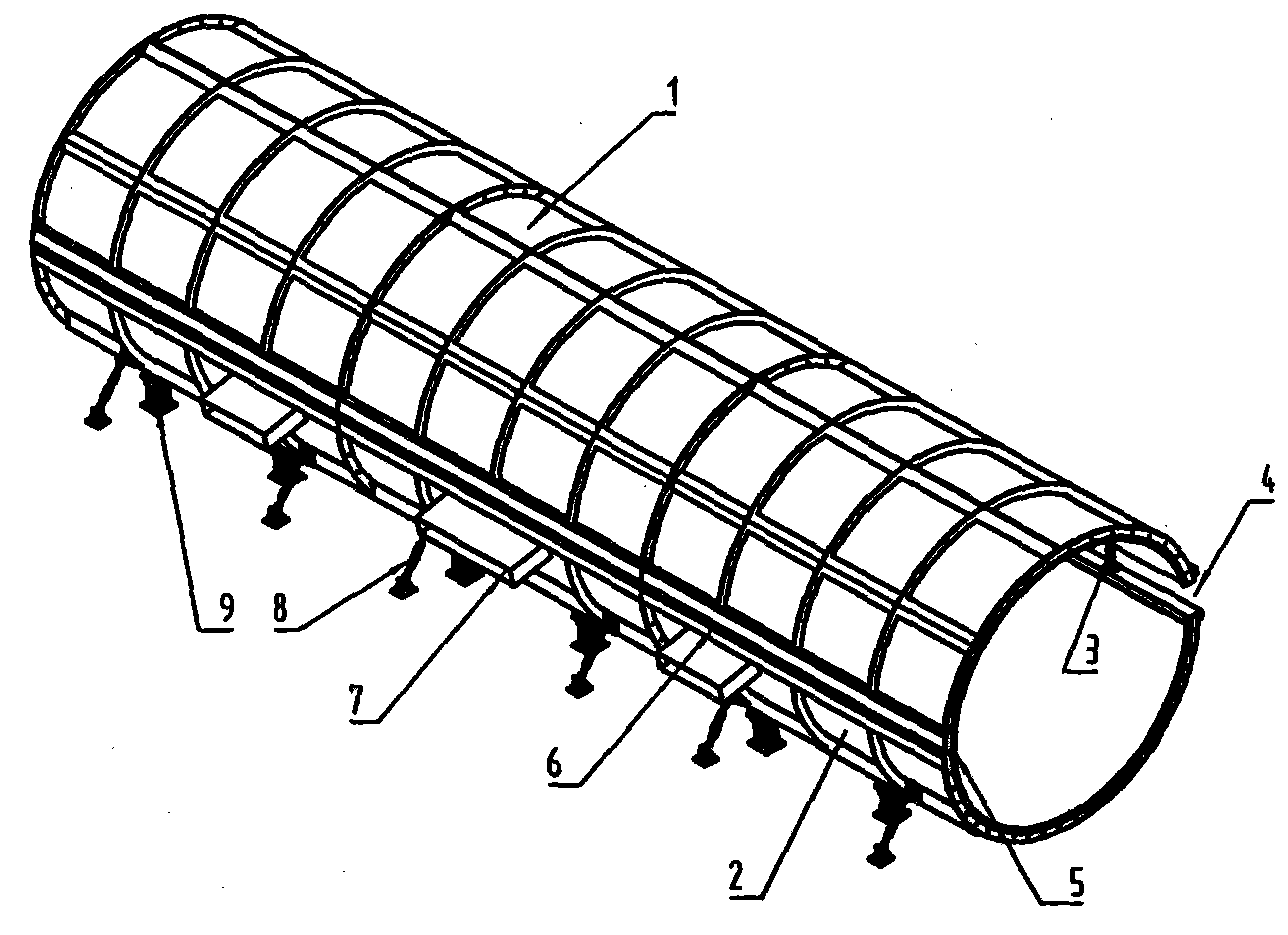

[0023] A semi-drum-shaped upper heat-collecting cover 1 is arranged above the semi-drum-shaped lower heat-collecting cover 2 to form a drum body heat-collecting cover, and a rotary kiln 10 is arranged inside the drum-shaped heat-collecting cover. Asbestos heat-resistant plates are arranged between 10, so that a sealed heat exchange channel 11 is formed between the drum body heat collecting cover and the rotary kiln 10; on one side of the drum body heat collecting cover, the upper heat collecting cover 1 and the lower heat collecting cover 2 Multiple sets of adjusting screw 3 are arranged between them, each group is at least 2, so that the cold air inlet 4 is formed between the upper heat collecting cover 1 and the lower heat collecting cover 2; 1 and the lower heat collecting cover 2 are provided with multiple sets of rotating hinge seats 6, each group is at least 2, an arc-shaped sealing plate 5 is arranged on the inner side between the upper heat collecting cover 1 and the lo...

Embodiment 2

[0025] The drum body heat collecting cover is divided into the whole drum body heat collecting cover and the combined drum body heat collecting cover, the combined drum body heat collecting cover is composed of at least two sections of the drum body heat collecting cover, the combined drum body An annular baffle 12 is arranged corresponding to the rotary kiln 10 between the adjacent two sections of the drum body heat collecting cover, and the annular baffle 12 makes each section of the drum body heat collecting cover and the rotary kiln 10 form an independent heat In the exchange channel 11, at least one hot air outlet 7 is arranged on the outer wall of the lower heat collecting cover 2 of each section of the drum body heat collecting cover.

Embodiment 3

[0027] The cold air enters the heat exchange channel 11 between the drum heat collecting cover and the rotary kiln 10 from the cold air inlet 4, and the cold air exchanges heat with the outer surface of the rotary kiln 10 in the heat exchange channel 11, so that the outer surface of the rotary kiln 10 Cool down, at the same time, the cold air in the heat exchange channel 11 is heated, by adjusting the vertical support 9 of the drum body heat collecting cover, the diameter adjustment screw 8 and the adjustment screw 3, the space and cooling capacity of the heat exchange channel 11 can be changed. The intake air volume of the air makes the temperature of the hot gas in the heat exchange channel 11 reach the set standard value, and the hot gas is sucked into the pipeline 15 by the high-temperature fan 14 from the hot blast outlet 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com