A test cable sealing device for simulating deep water environment explosion test container

A technology for testing cables and explosion tests, which is applied in the field of simulating explosion tests in deep water environments, can solve the problems of testing the compression performance of cable sealing devices, the sealing performance cannot meet the test requirements, etc., and achieves excellent sealing performance, simple and quick assembly, and improved sealing performance. Effect with compressive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

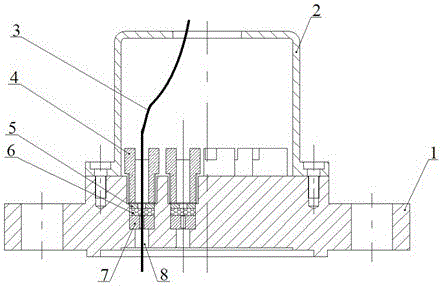

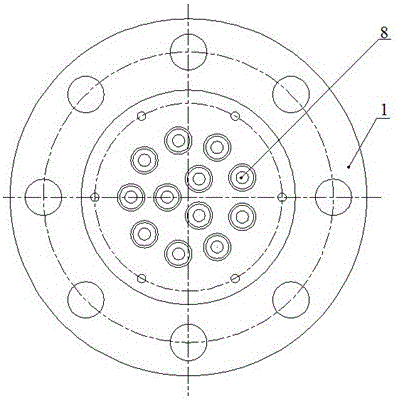

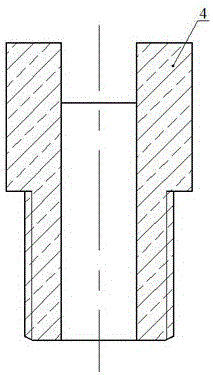

[0020] A test cable sealing device for simulating a container for explosion test in a deep water environment. Test cable sealing device such as figure 1 with figure 2 As shown, it includes a flange cover 1, a protective cover 2 and a compression bolt 4; the flange cover 1 is fixedly connected to a container for an explosion test in a simulated deep water environment through a test cable adapter flange. The upper horizontal plane of the flange cover 1 is equipped with a protective cover 2 at the same center, 12 cable holes 8 are evenly arranged around the center of the flange cover 1, and the center distance between the cable holes 8 is the outer diameter of the upper end of the compression bolt 4 1.6 times of that, 12 cable holes 8 are located in the protective cover 2. Each cable hole 8 is a through hole composed of three aperture sections, the lower one is smaller and the upper one is larger. The middle section of each cable hole 8 is concentrically provided with a blocking ...

Embodiment 2

[0026] A test cable sealing device for simulating a container for explosion test in a deep water environment. Except for the following technical parameters, the rest are the same as in Example 1:

[0027] There are 2~11 cable holes 8 evenly around the center of the flange cover 1, the center distance between the cable holes 8 is 1.6~2.0 times the outer diameter of the upper end of the compression bolt 4, and 2~11 cable holes 8 are located Inside the protective cover 2;

[0028] The diameter of the through hole of the compression bolt 4 is 1.6 to 2.0 times the diameter of the test cable 3, and the depth of the rectangular groove is 2.0 to 2.2 times the diameter of the test cable 3;

[0029] The inner diameter of the ring gasket 5 is 1.3 to 1.5 times the diameter of the test cable 3;

[0030] The blocking block 7 is composed of two semi-annular blocks, and the inner diameter of the semi-annular block is 1.1 to 1.2 times the diameter of the test cable 3.

Embodiment 3

[0032] A test cable sealing device for simulating a container for explosion test in a deep water environment. Except for the following technical parameters, the rest are the same as in Example 1:

[0033] 13-15 cable holes 8 are evenly arranged around the center of the flange cover 1, the center distance between the cable holes 8 is 1.5-1.6 times the outer diameter of the upper end of the compression bolt 4, and 13-15 cable holes 8 are located Inside the protective cover 2;

[0034] The diameter of the through hole of the compression bolt 4 is 1.5 to 1.6 times the diameter of the test cable 3, and the depth of the rectangular groove is 2.2 to 3.0 times the diameter of the test cable 3;

[0035] The inner diameter of the ring gasket 5 is 1.2 to 1.3 times the diameter of the test cable 3;

[0036] The blocking block 7 is composed of two semi-annular blocks, and the inner diameter of the semi-annular block is 1.05~1.1 times the diameter of the test cable 3.

[0037] Compared with the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com