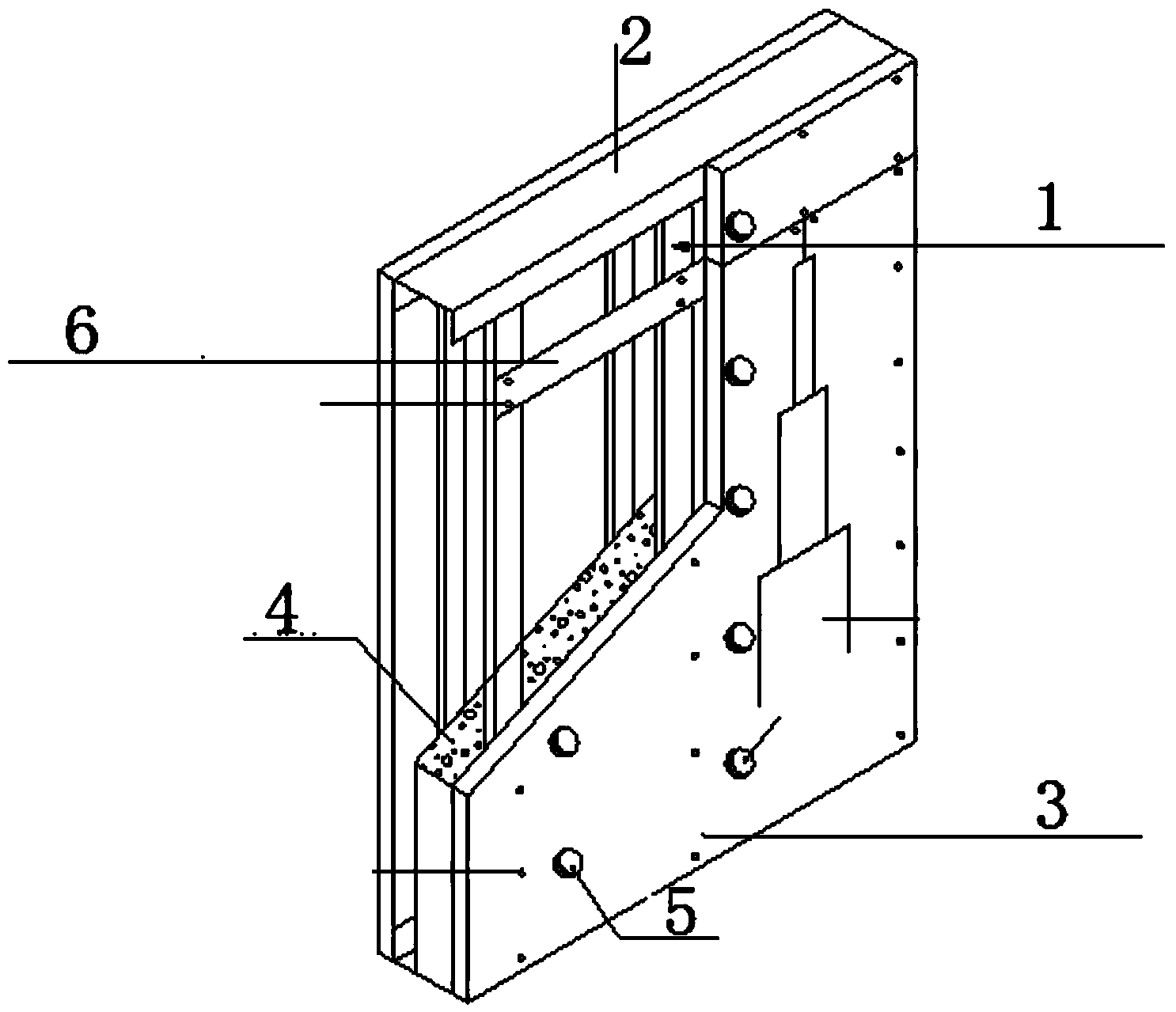

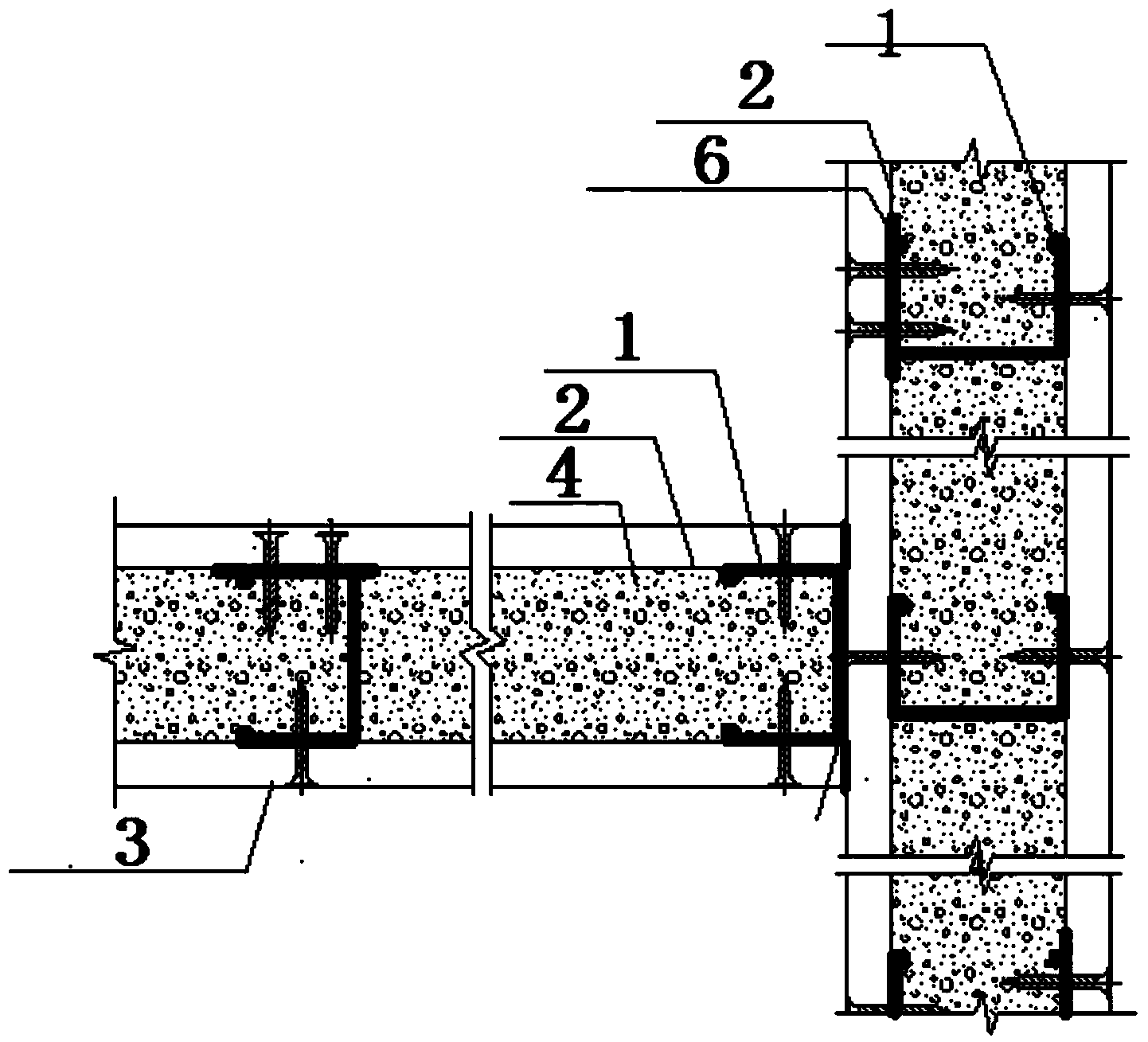

Construction method for integrally grouting wall by lightweight concrete through CCA board

A lightweight concrete and grouting wall technology, which is used in construction, building structure, and building material processing, etc., can solve problems such as imperviousness to impact, complex construction process, poor fire resistance, etc., to reduce costs and improve the use of indoor space. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The construction method of CCA board lightweight concrete monolithic grouting wall of the present invention is characterized in that: comprises the following steps successively:

[0015] a) According to the design drawings and the instructions of the construction drawings approved by the on-site engineering personnel, the horizontal and vertical datum lines are first placed on the construction site, and the construction technicians then mark the position of the partition wall and the door frame according to the horizontal and vertical datum lines on the site; Under the principle of the original intention of the picture, pay attention to the adjustment of the structure and on-site size; fix the upper and lower keels to the upper and lower floors with nails or expansion bolts according to the lofting line of the partition wall, fix the first branch at 5cm from the broken end of the keel, and then stagger at a distance of about 50-60cm fixed;

[0016] b) After the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com