A trimming mold

A trimming mold and trimming technology, applied in the field of die-casting molds, can solve the problems of affecting product quality, increasing production costs of enterprises, time-consuming and labor-intensive problems, and achieve the effect of improving the efficiency of trimming and ensuring the quality of trimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

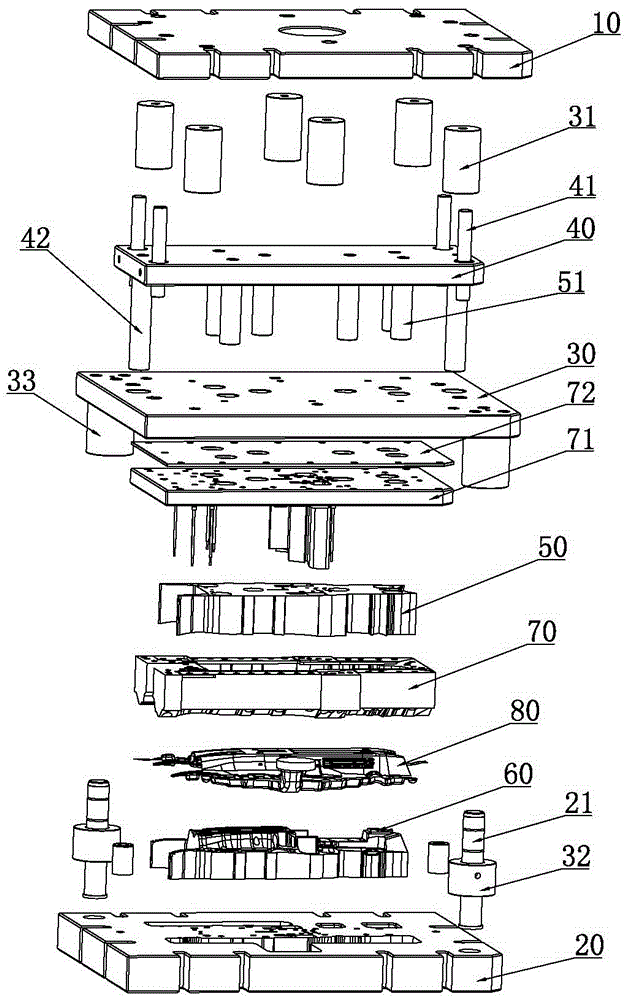

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] like Figure 1 to Figure 4 As shown, a kind of trimming mold of the present invention comprises the upper formwork 10 and the lower formwork 20 that cooperate with each other, and the opposite corner of the lower formwork 20 is equipped with the lower formwork guide post 21 symmetrically, between the lower formwork 20 and the upper formwork 10 A middle plate 30 is provided, an upper platen 40 is arranged between the middle plate 30 and the upper formwork 10, a product presser 50 is arranged between the middle plate 30 and the lower formwork 20, and the product presser 50 passes through the product that is installed on the middle plate 30 The platen connecting column 51 is fixedly connected with the upper platen 40 , the product backing plate 60 is arranged between the product platen 50 and the lower template 20 , and the edge trimming cutter 70 connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com