Die-cutting device special for groove strips such as guide grooves in car door and die-cutting blade of device

A technology of grooved strips and punching knives, which is applied in the field of special punching devices for grooved strips, can solve the problems of difficulty in ensuring machining accuracy and low operating efficiency, and achieve the effect of high punching accuracy and improved operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

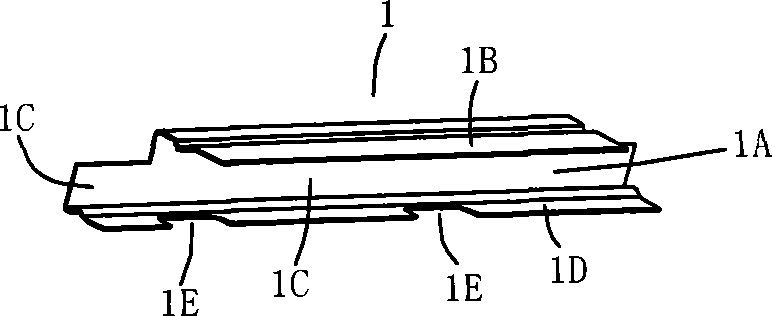

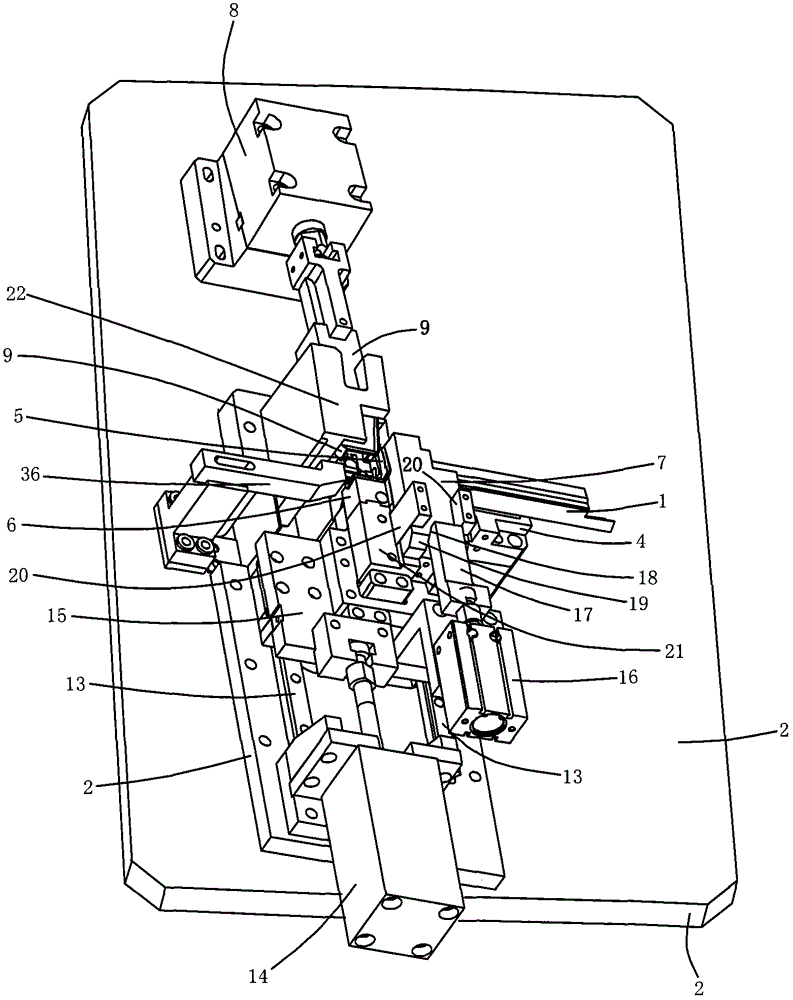

[0039] The special punching device for the groove bar of the present embodiment one is as follows: image 3 as shown, for figure 1 , figure 2 The end punching of the grooved strip workpiece 1 is shown. When punching, the grooved strip workpiece 1 is placed in a lateral vertical manner and then punched to its end; the punching device includes a base plate 2, and the shape of the contact surface that contacts the workpiece 1 is arranged on the base plate 2 to match the corresponding surface of the workpiece 1. Workpiece shelving block 4, workpiece inner stopper 5, and workpiece clamping mechanism for clamping the grooved bar workpiece 1 standing sideways. The workpiece clamping mechanism includes workpiece outer clamping block 6 and workpiece upper pressure block 7 driven by a power device The punching device also includes an end punching mechanism; the end punching mechanism includes a first oil cylinder 8 fixedly installed on the rear side of the bottom plate 2 in a horizon...

Embodiment 2

[0050] The special punching device for the groove bar in the second embodiment is a multi-directional combined punching device, such as Figure 11 as shown, for figure 1 , figure 2 The end punching of the grooved strip workpiece 1 is shown on the same machine as the lower side piece. When punching, the workpiece 1 of the grooved strip is placed in a lateral vertical manner; the punching device includes a base plate 2 and a shelf 3 fixedly placed above the base plate 2, and the shape of the contact surface and the groove in contact with the workpiece 1 are arranged on the base plate 2 The corresponding surface of the strip workpiece 1 matches, and is used to clamp the workpiece resting block 4, the workpiece inner stopper 5, and the workpiece clamping mechanism of the grooved strip workpiece 1 erected sideways. Block 6 and pressing block 7 above the workpiece; the punching device also includes an end punching mechanism and a lower side piece punching mechanism. The end punc...

Embodiment 3

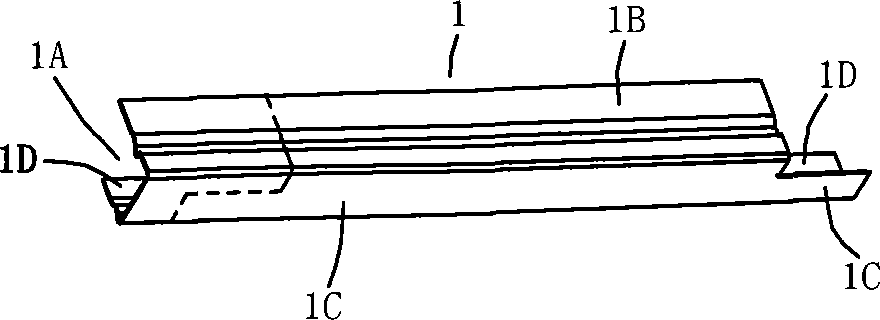

[0055] Such as Figure 12 Shown is an upper guide groove of an automobile door, which is also a groove bar with a concave cross section. The upper guide groove of a car door is generally formed by a continuous rolling process of metal strips, and is formed by an upper side piece 1B, a groove bottom 1C, a lower The groove 1A surrounded by the side piece 1D is cut off online; often for its installation needs, the end and side piece of the cut-off door upper guide groove need to be punched; the end is punched into the upper side piece 1B , the ends of the groove bottom 1C and the lower side panels 1D of different lengths are cut off, and the side panels are punched into notches or punched holes; before punching, the ends are as figure 2 The left end of the dotted line takes the left part as the part to be cut off. After punching, such as Figure 12 As shown, the part to be cut off at the end includes the end of the upper side piece 1B, the end of the groove bottom 1C, and the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com