Steamed bun zymophyte, preparation method thereof and application of steamed bun zymophyte

A fermentation inoculum and a technology for steamed bread, which are applied in the field of old-flour steamed bread fermentation inoculum and its preparation, can solve the problems of pure yeast steamed bread with a thin fragrance, failure to realize industrialized production, and the like, and achieve excellent flavor and taste, easy large-scale production, Ease of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

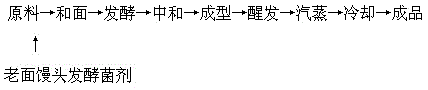

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Preparation of fermented bacteria agent for steamed bread with old noodles

[0039] Weigh the live bacteria content as 2.0×10 10 CFU / g Angel brand high active dry yeast 10g, live bacteria content is 2.5×10 10 CFU / g Lactobacillus plantarum powder 8g (Lactobacillus plantarum with strain number SICC1.566), live bacteria content is 4.1×10 9 CFU / g Lactobacillus casei powder 1g (Lactobacillus casei with strain number SICC1.390), live bacteria content is 3.7×10 9 CFU / g Lactobacillus acidophilus powder 0.5g (Lactobacillus acidophilus strain number SICC1.369), put it into a small mixer with a volume-to-weight ratio of 0.3 and mix for 10 minutes; after mixing, add the bacteria powder Add 80.5 g of edible anhydrous glucose, put it into a V-shaped mixer with a volume-to-weight ratio of 0.5, and mix for 10 minutes to obtain the old-faced steamed bread fermentation bacterial agent.

Embodiment 2

[0040] Example 2 Production of Old-faced Steamed Buns

[0041] Raw materials: flour 1000g, water 450g;

[0042] Auxiliary materials: 5 g of fermented steamed buns prepared in Example 1, 5 g of baking soda.

[0043] 1) Weigh 700g of flour, 400g of water and 5g of old noodle steamed bread fermentation bacteria, stir in a single-axis S-type or zigzag type dough mixer for 10 minutes, and put it into fermentation when the dough is not sticky, elastic and smooth. cylinder, the dough temperature is 30°C;

[0044] 2) Cover the fermentation tank with a damp cloth, and ferment for 3 hours in a fermentation room with a room temperature of 26-28°C and a relative humidity of 75%, until the volume of the dough doubles, the internal honeycomb structure is uniform, and there is an obvious sour taste;

[0045] 3) Put the fermented dough into the dough mixer, gradually add baking soda water to neutralize the acidity produced after fermentation, then add the remaining dry flour and water, and ...

Embodiment 3

[0049] Example 3 Preparation of fermented bacteria agent for old noodle steamed bread

[0050] Weigh the live bacteria content to be 3.6×10 10 CFU / g Angel brand high active dry yeast powder 15g, live bacteria content is 1.7×10 10 CFU / g Paulome Lactobacillus plantarum powder 5g, live bacteria content is 5.7×10 9 CFU / g of Paulome Lactobacillus acidophilus powder and Paulome Lactobacillus casei powder 0.5g each, put into a mixer with a volume-to-weight ratio of 0.5, and mix for 20 minutes or more; after mixing, add the bacteria powder to the Put 79g of edible anhydrous glucose into a mixer with a volume-to-weight ratio of 0.7, and mix for 20 minutes to obtain the fermented bacteria agent for old-fashioned steamed buns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com