Two-degree-of-freedom motion platform based on piezoelectric ultrasonic vibrator driving

A piezoelectric ultrasonic, motion platform technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve problems such as electromagnetic interference, complex structure, complex self-locking, etc. , to achieve the effect of simple mechanism, improved work reliability, simplified processing and assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

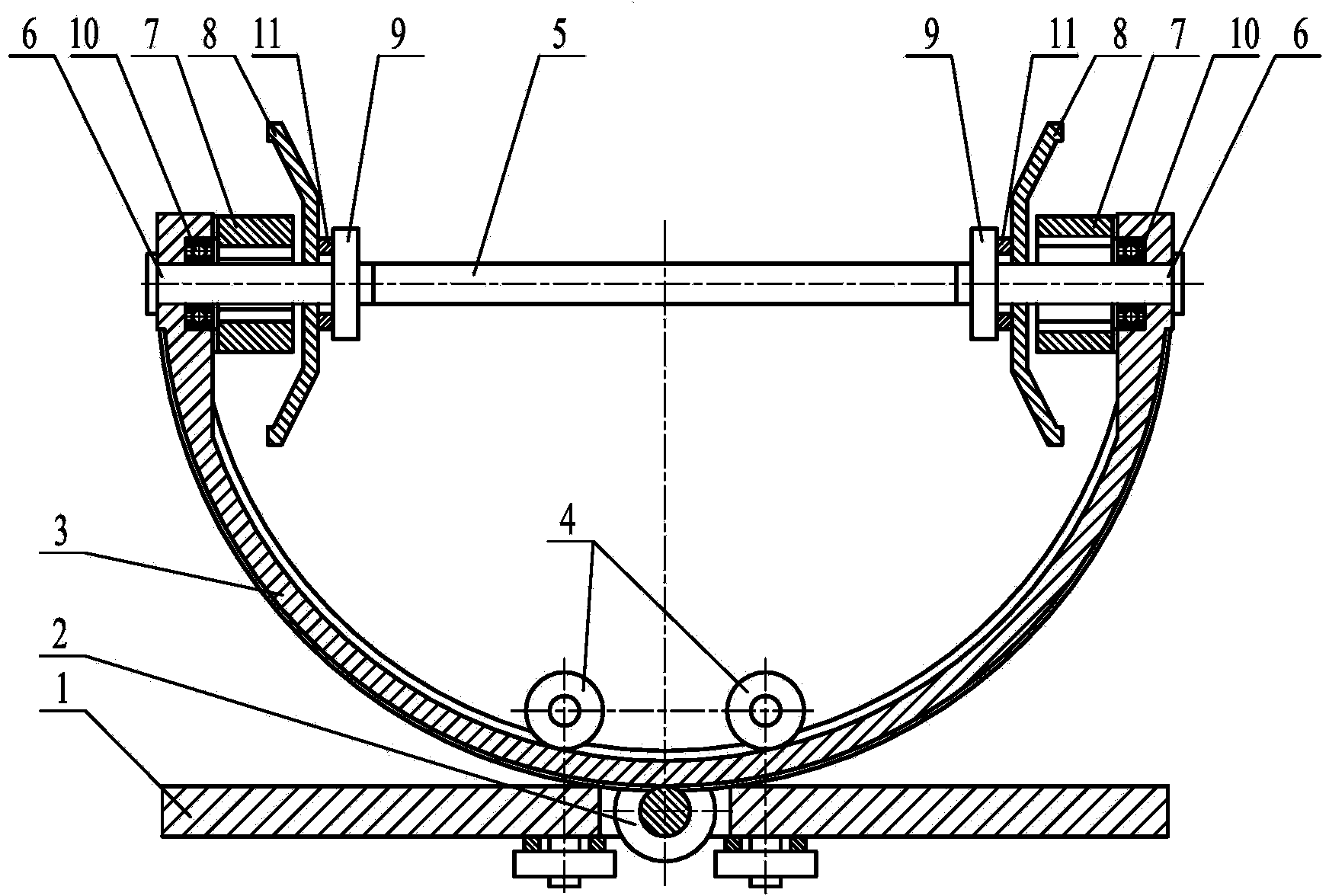

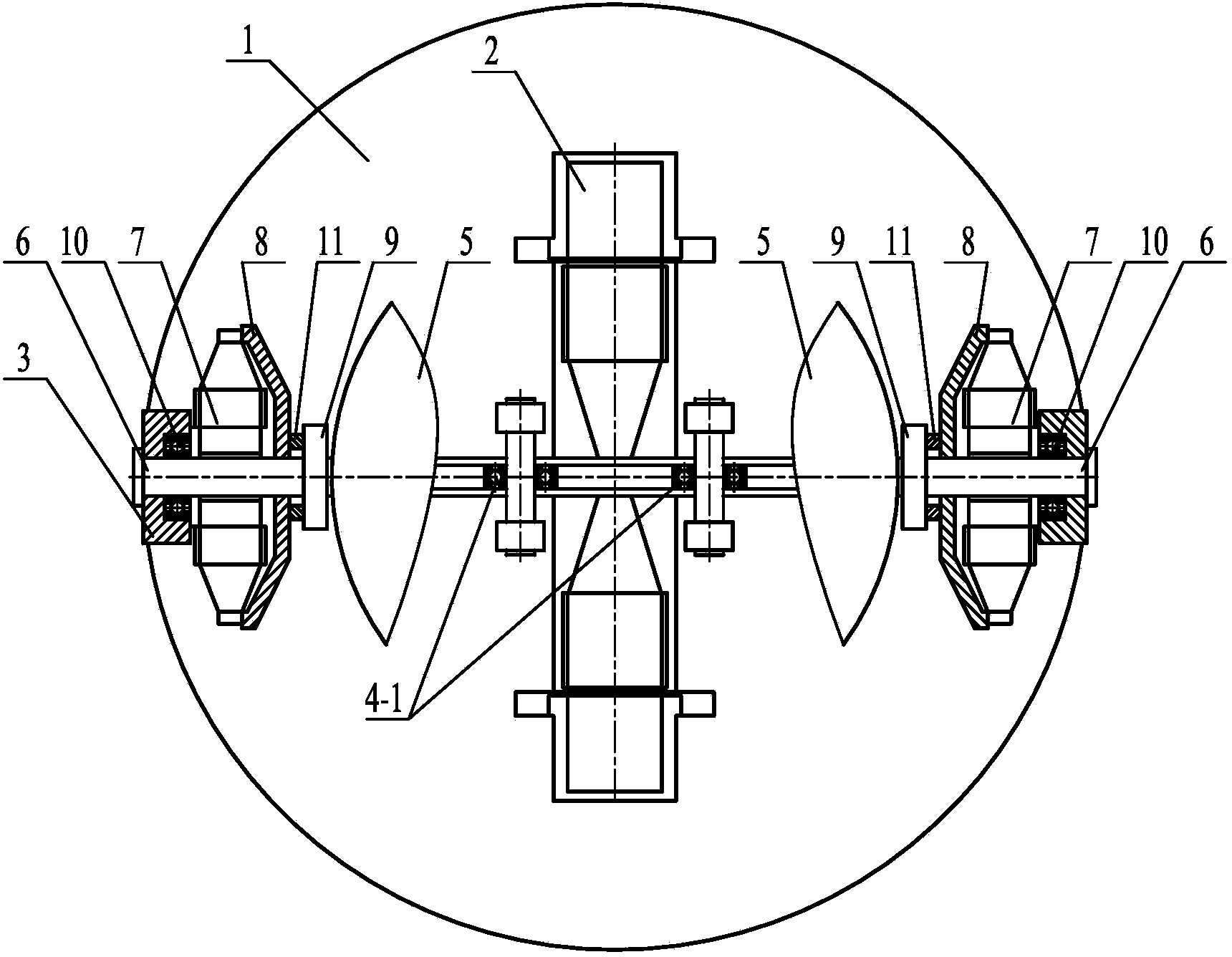

[0018] Specific implementation mode one: the following combination Figure 1 to Figure 6 Describe this embodiment. The two-degree-of-freedom motion platform driven by piezoelectric ultrasonic vibrators described in this embodiment includes a base 1, an outer ring piezoelectric ultrasonic vibrator 2, an outer ring 3, and two sets of outer ring preloading components 4. , moving platform 5, two inner ring mandrels 6, two inner ring piezoelectric ultrasonic vibrators 7 and two disc rotors 8;

[0019] The outer ring 3 is an arc-shaped track, and its inner and outer surfaces are provided with through grooves;

[0020] The outer ring piezoelectric ultrasonic vibrator 2 includes a driving foot 2-3 and a mounting seat 2-4, the outer ring piezoelectric ultrasonic vibrator 2 is fixedly connected to the base 1 through the mounting seat 2-4, and the driving foot 2- 3 Embedding in the through groove on the outer surface of the outer ring 3 and closely contacting the bottom of the through g...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment further defines the two-degree-of-freedom motion platform driven by piezoelectric ultrasonic vibrators described in Embodiment 1. In this embodiment, it includes a base 1 and an outer ring piezoelectric ultrasonic vibrator 2 , outer ring 3, two sets of outer ring preloading components 4, moving platform 5, two inner ring mandrels 6, two inner ring piezoelectric ultrasonic vibrators 7, two disc rotors 8, two lock nuts 9, Two bearings 10 and two disc springs 11;

[0025] The outer ring 3 is an arc-shaped track, the central angle of the arc-shaped track is 180o, and its inner and outer surfaces are provided with through grooves;

[0026] The outer ring piezoelectric ultrasonic vibrator 2 includes a metal base 2-1, a piezoelectric ceramic sheet 2-2, a driving foot 2-3 and a mounting seat 2-4, and the outer ring piezoelectric ultrasonic vibrator 2 is a metal base 2-1 and Piezoelectric ceramic sheet 2-2 is a composite formed by sticking or clamp...

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment further defines the two-degree-of-freedom motion platform driven by piezoelectric ultrasonic vibrators described in Embodiment 1. In this embodiment, each inner ring mandrel 6 and outer ring 3 Bearings 10 are arranged between the ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com