Semiconductor device, method of manufacturing semiconductor device, and antenna switch module

A semiconductor and device technology, applied in the field of semiconductor device manufacturing methods and antenna switch modules, can solve the problems of n-channel MOSFET threshold voltage drop, polysilicon resistance rise, field strength rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0052] (B) Second Embodiment

[0053] (C) Third Embodiment

[0054] (D) Fourth embodiment

[0055] (E) Fifth Embodiment

[0056] (F) Summary of Example Implementations

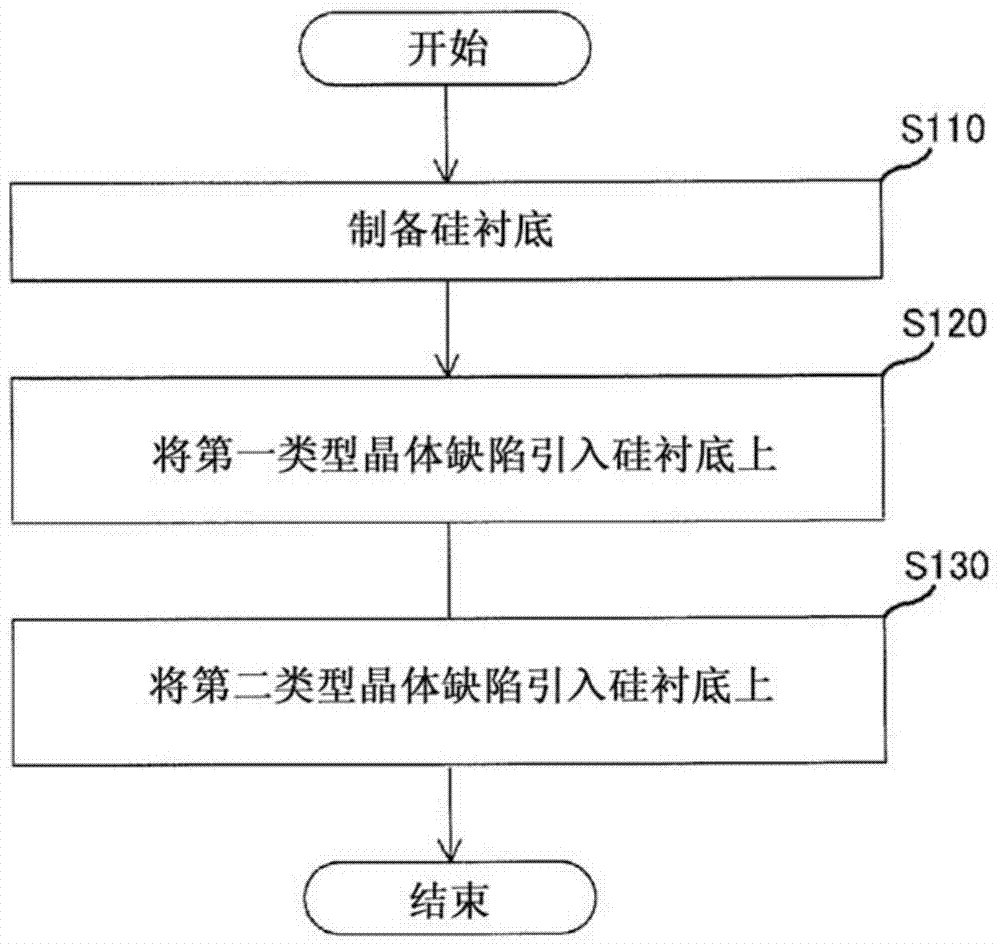

[0057] (A) First Embodiment

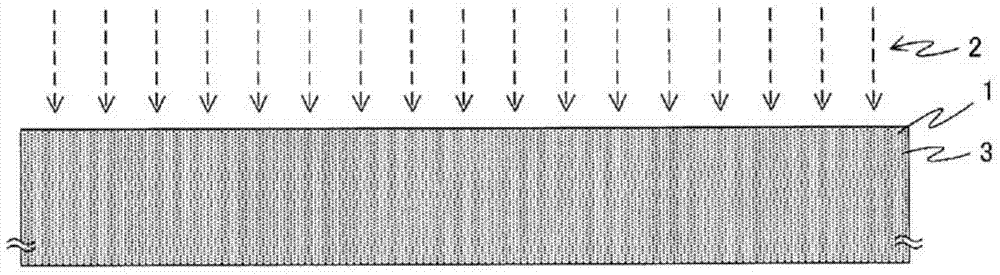

[0058] figure 1 is a flowchart showing the flow of the manufacturing method of the semiconductor device according to the first embodiment of the present disclosure, and Figure 2 to Figure 5 respectively with figure 1 Cross-sectional views of the semiconductor device corresponding to each step of the fabrication method shown in . Hereinafter, along figure 1 The flow of the fabrication method shown in provides a description.

[0059] exist figure 1 In the fabrication method shown in , as a start, prepare as figure 2 Shown is a silicon substrate 1 used as a base of a crystal defect introducing substrate ( S110 ). figure 2 is a cross-sectional view of the silicon substrate 1 .

[0060] For the silicon substrate 1, an oxygen concentration of about 1×10 produced by the FZ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com