High-frequency transformer winding conducting wire

A high-frequency transformer and winding technology, applied in the direction of transformer/inductor coil/winding/connection, flat/ribbon cable, etc., can solve the problems of increased processing difficulty, difficult winding, uneven winding, etc., to achieve The effect of improving performance, improving winding efficiency, and reducing winding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

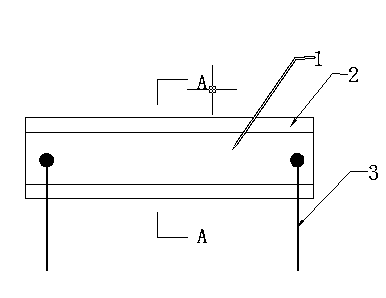

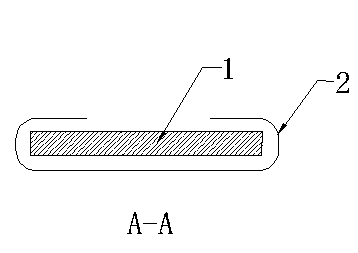

[0013] The high-frequency transformer winding wire of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] As shown in the figure, the high-frequency transformer winding wire of the present invention includes a flat copper strip body 1, that is, a copper strip with the same cross-sectional area as the multi-strand wire, (the thickness and width are determined according to the skeleton size) and processed; The periphery of the copper strip body 1 is coated with an insulating tape 2, the insulating tape 2 covers the bottom surface of the entire copper strip body 1 and the lateral sides of the insulating tape are respectively covered on the lateral sides above the copper strip body, and the upper middle part of the copper strip body 1 Bare, lead wires 3 are welded to the longitudinal two ends of the middle exposed part above the copper strip body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com