Developing method

A developing method and developing solution technology, applied in the processing of photosensitive materials, etc., can solve problems such as uneven development, achieve the effect of shortening coating time and improving line width uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

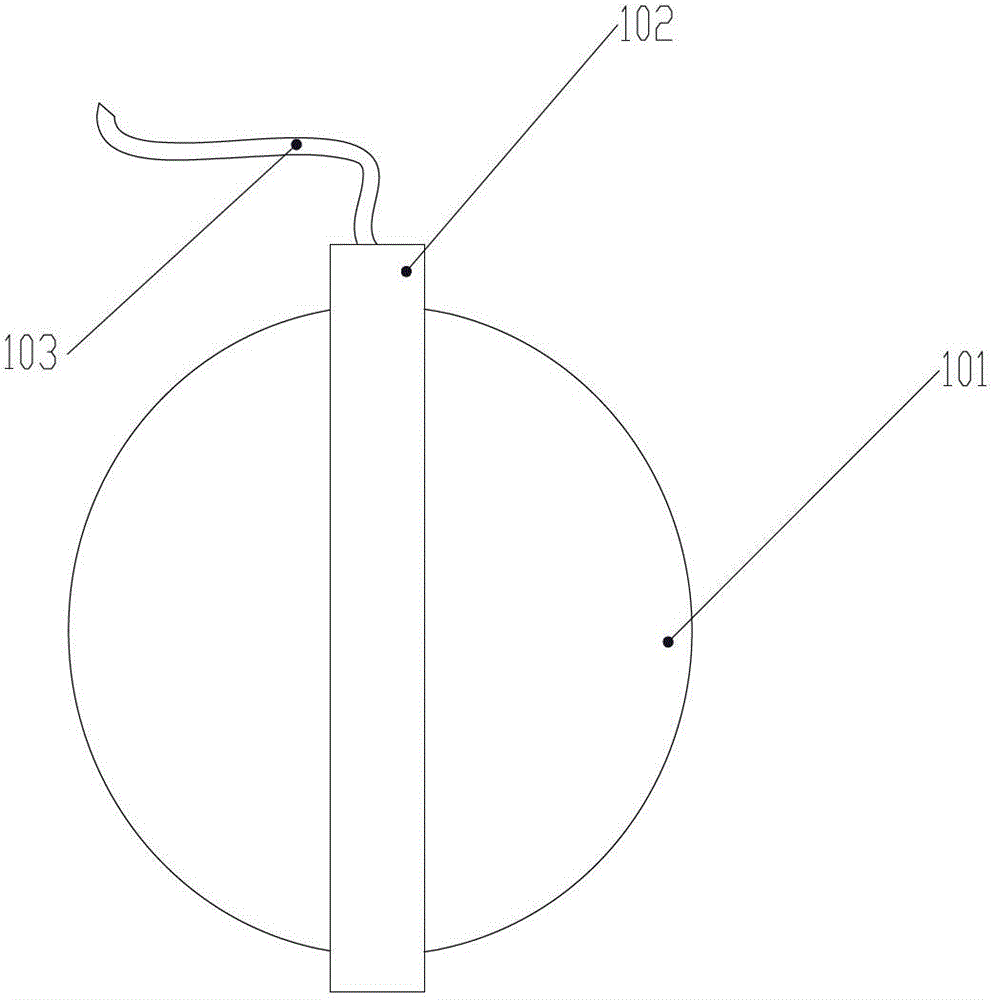

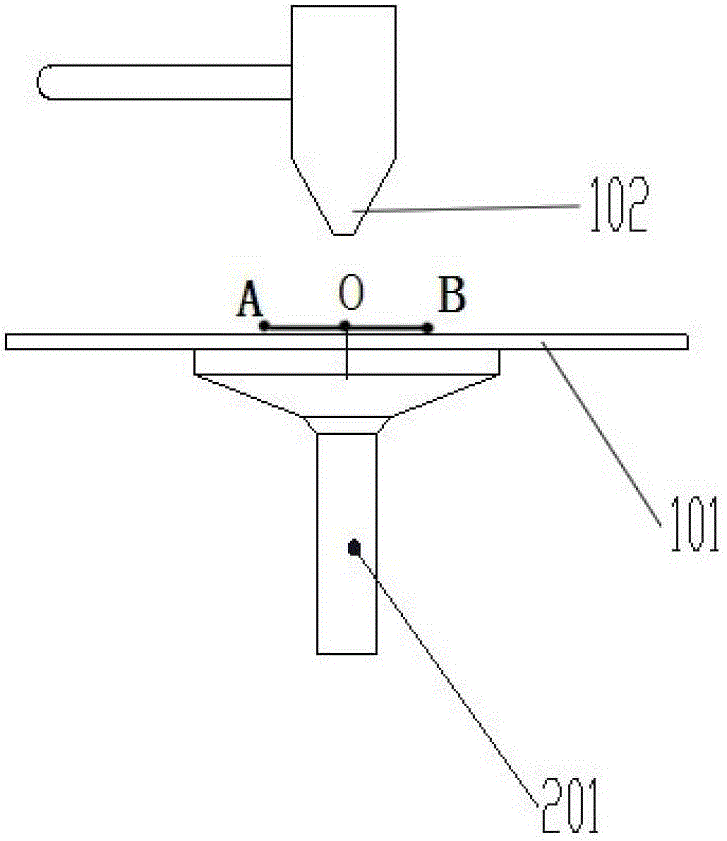

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] The schematic diagram of the developing method of the present invention is as Figure 1-2 As shown, the method includes the following steps: first, the wafer 101 whose surface is coated with photoresist and whose exposure process has been completed is fixed on the wafer stage 201 of the developing device, and the wafer 101 can rotate with the wafer stage 201, The developing nozzle 102 is connected with the nozzle pipe 103, and the developer is input into the developing nozzle 102 through the nozzle pipe 103, and then sprays wine on the surface of the wafer for development. The length of the developing nozzle 102 is greater than the diameter of the wafer 101 .

[0018] Before developing, the developing nozzle 102 is located directly above the initial position point A on the side of the center (O point) of the wafer 101, and OA=10-20cm. The rotation rate of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com