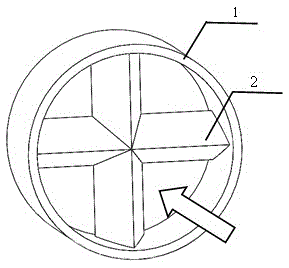

Sludge diversion device with knife

A shunting device and slicing technology, which is applied in the direction of combustion method, lighting and heating equipment, combustion type, etc., can solve the problems of quenching and quenching damage of the wind cap, and achieve the effect of reducing weight, reducing cost and increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] The device of the present invention is applied in a biochemical sludge fluidized bed incineration project of a certain pharmaceutical factory. In this project, the water content of the sludge is 70% to 80%, and the incineration capacity is 100 tons / day. Before the device of the present invention is installed, the wet sludge is directly transported to the fluidized bed through the sludge pump in the sludge bin. The boiler is incinerated, and the diameter of the sludge conveying pipe is Φ219×7. Because the large sludge directly enters the fluidized bed, and cannot be diffused out in time, the low-temperature sludge may directly contact the high-temperature air cap, resulting in frequent quenching and quenching damage to the air cap. Within half a year, multiple hoods were damaged, which resulted in 2 shutdowns for maintenance. The device is welded on the lower part of the original sludge pipeline. Before the sludge enters the boiler, the sludge is quickly divided into 4 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com