Polymer surface grafting method for carbon fiber

A surface grafting, carbon fiber technology, applied in the direction of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of solvent unfriendly monomer selection, difficult control of conditions, and high system temperature, to improve the interface bonding quality, simple operation, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

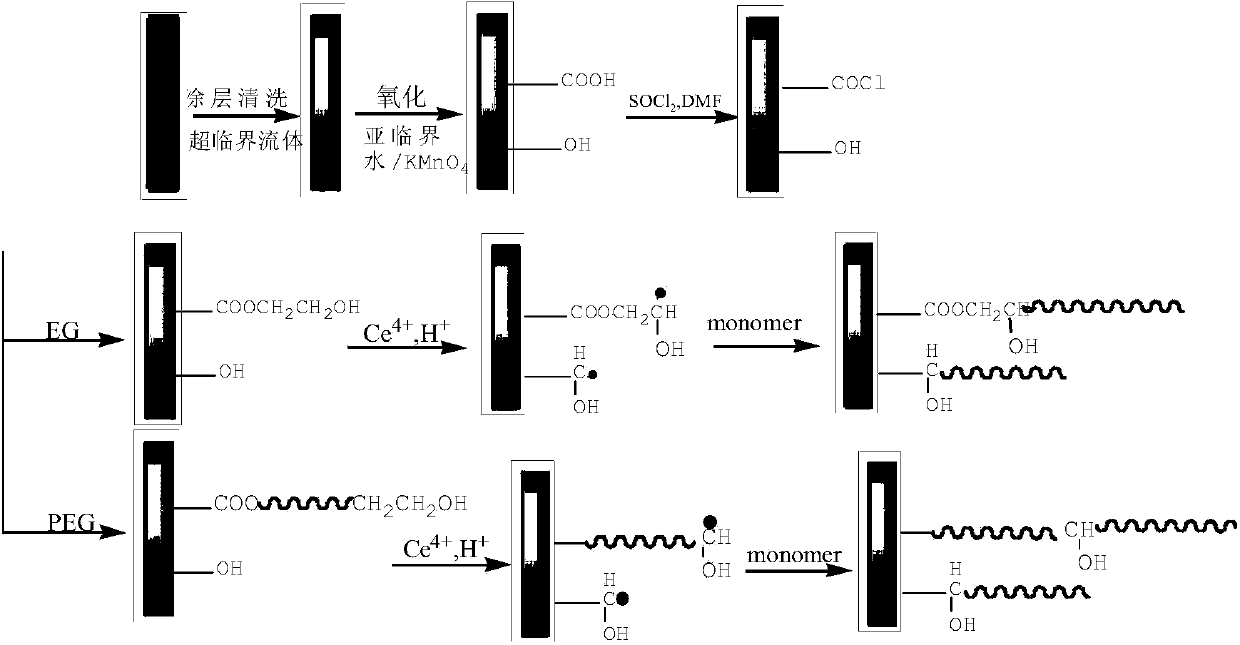

[0035] Specific embodiment one: the method for grafting polymer on the surface of a carbon fiber in this embodiment is carried out through the following steps:

[0036] 1. Remove the epoxy coating;

[0037] 2. Oxidized carbon fiber: at room temperature, prepare 35-50ml of a mixed solution of potassium permanganate and sulfuric acid, wherein the dosage of potassium permanganate is 0.35-0.60g, the concentration of sulfuric acid is 1-2mol / L, and then the mass Put 0.35~0.70g of carbon fiber into the mixed solution of potassium permanganate and sulfuric acid, pour it into a glass test tube, put it into a supercritical device, and react in a system with a temperature of 320~340°C and a pressure of 2~5MPa 15-25min, then take out the carbon fiber, put it into a beaker filled with hydrochloric acid with a mass concentration of 37.5%, seal it well, put it in a water bath at 55-65°C, soak it for 2-4h, and put it into the Soxhlet extractor again , at 80°C, wash the carbon fibers with eth...

specific Embodiment approach 2

[0047] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the method for removing the epoxy coating described in step one is: put the carbon fiber bundle in the Soxhlet extractor, heat the acetone in the Soxhlet extractor to 75-85°C, keep it for 2-8 hours, then put it into a supercritical device, soak it in a supercritical acetone-water system with a temperature of 350-370°C and a pressure of 8-14MPa for 20-30min, and then put it into the cable again. In the extractor, clean the carbon fiber in acetone at 75-85°C for 2-4 hours, then take out the carbon fiber and dry it in an oven at 70-80°C for 2-4 hours, and the process is complete. Others are the same as the first embodiment.

specific Embodiment approach 3

[0048] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the supercritical acetone-water system is composed of 25 mL of acetone and 5 mL of water. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com