Tinned copper strip tin layer regulating mechanism for copper strip tinning machine

A technology of tinned copper strip and adjustment mechanism, which is applied in coating, hot-dip plating process, metal material coating process, etc., can solve the problems of uneven air flow and instability, achieve small distance changes, safe and reliable use, small error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

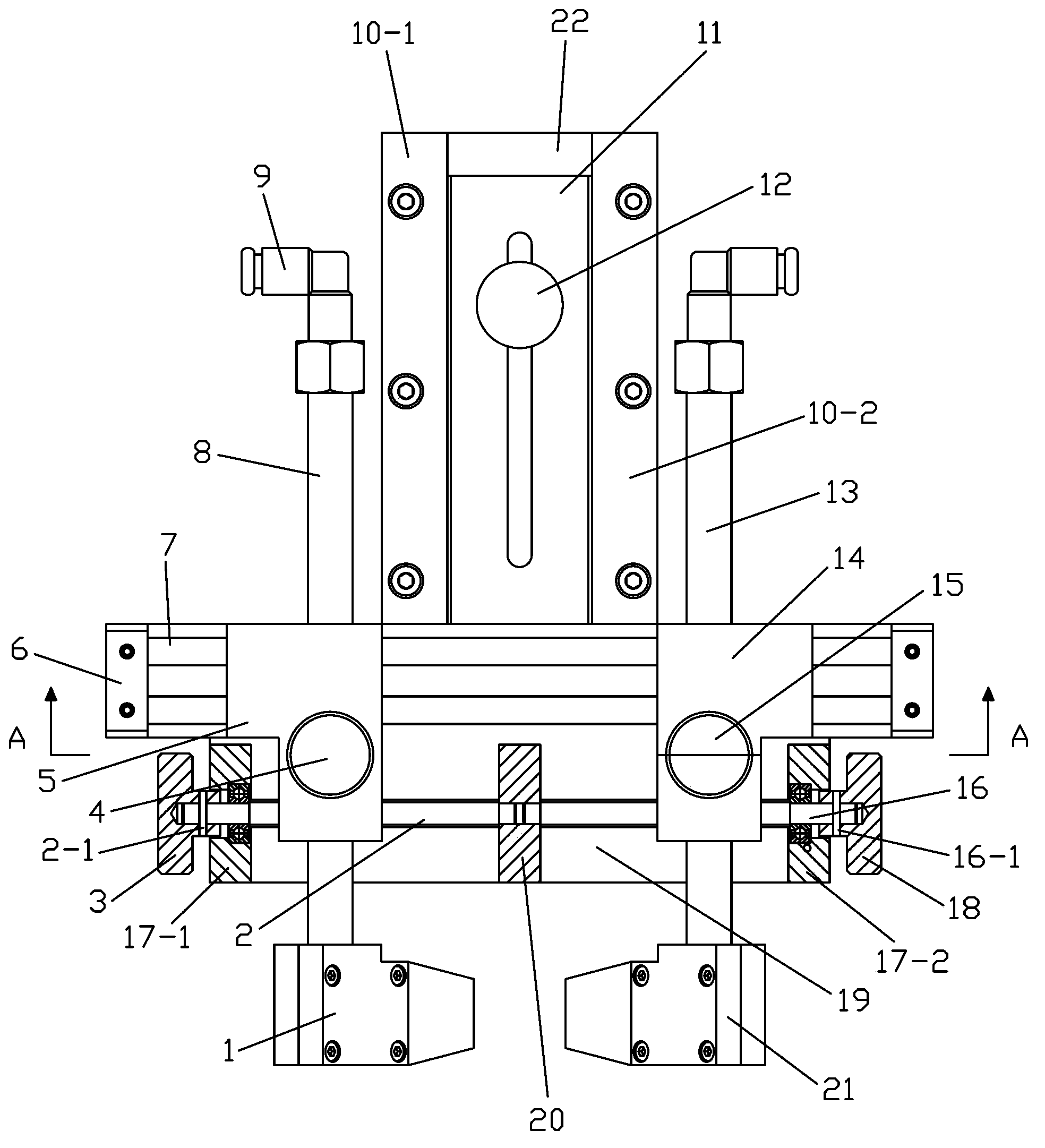

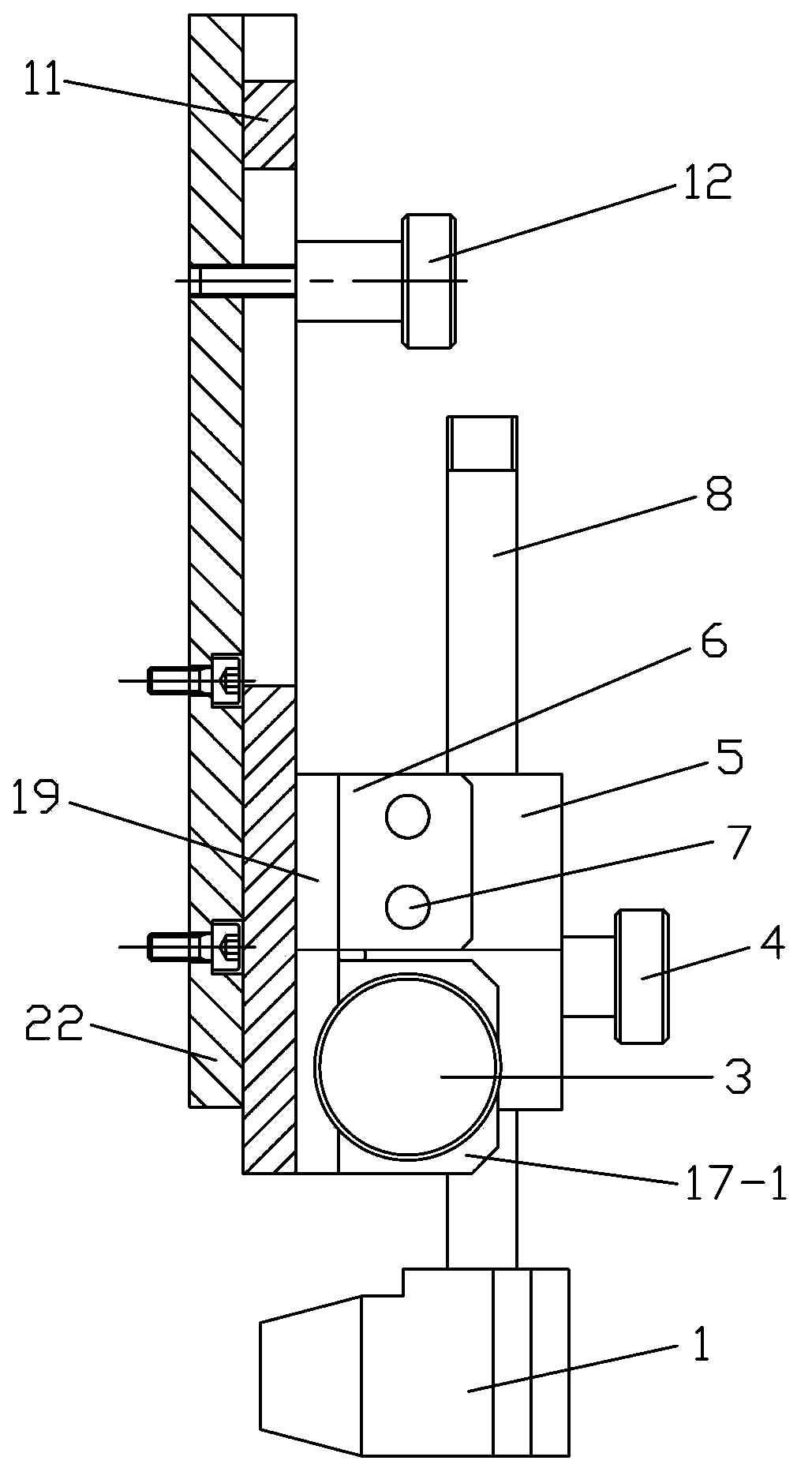

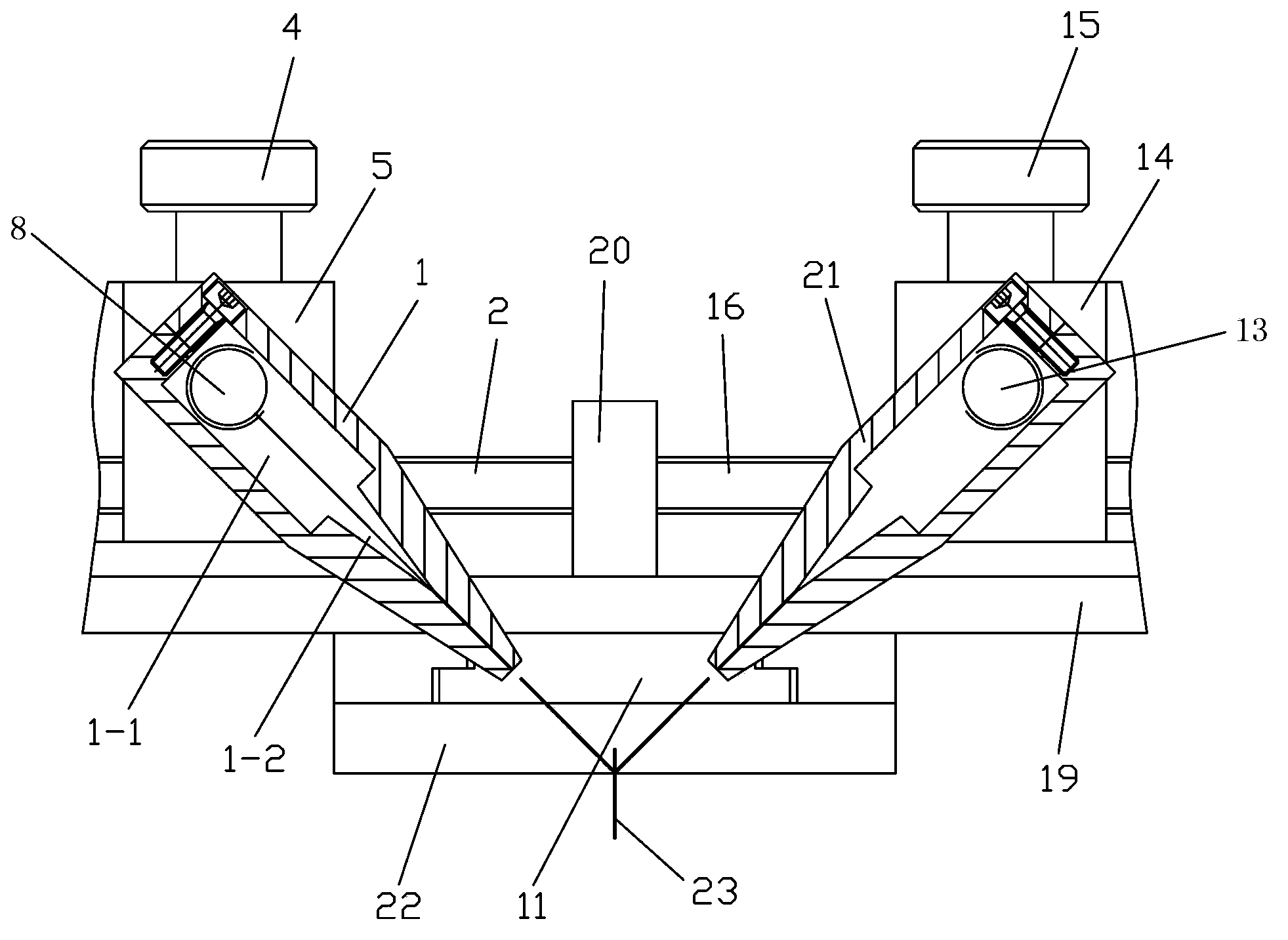

[0031] Such as Figure 1 to Figure 3 Shown, the present invention comprises base plate 22, left guide plate 10-1, right guide plate 10-2, moving plate 11, connecting plate 19, guide rod support 6, guide rod 7, left screw mandrel support 17-1, Right screw mandrel support 17-2, middle support plate 20, left screw mandrel 2, right screw mandrel 16, left slide block 5, right slide block 14, left air pipe 8 and right air pipe 13, described left guide plate 10 -1 and the right guide plate 10-2 are all fixed on the base plate 22, and the moving plate 11 is located between the left guide plate 10-1 and the right guide plate 10-2 and between the left guide plate 10-1 and the right guide plate 10 -2 moves up and down under the guiding action, the moving plate 11 is provided with a positioning screw 12 for positioning it, the connecting plate 19 is fixed on the bottom of the moving plate 11, the guide rod support 6, the left screw rod Bearing 17-1, right screw mandrel support 17-2 and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com