A method and device for underwater laser shock strengthening of prismatic shaped holes

A laser shock strengthening and impact strengthening technology, which is applied to the strengthening of the inner wall and edge of the prismatic shaped hole, and the field of underwater laser shock strengthening of the prismatic shaped hole. It can improve the service life, reduce the number of times, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

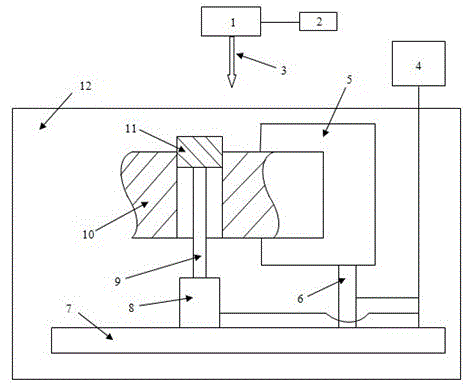

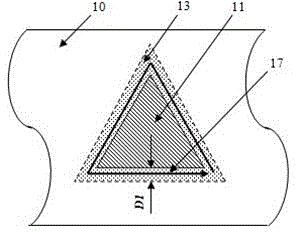

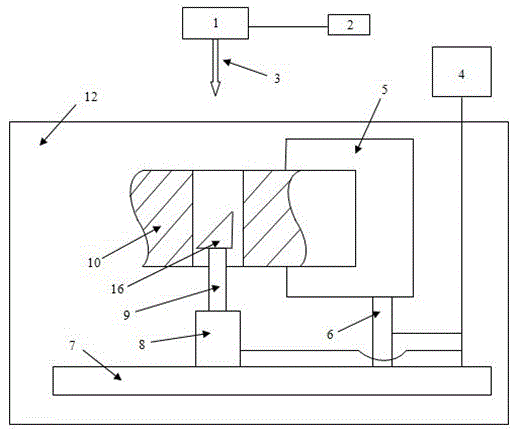

[0046] A device for laser shock strengthening of prismatic special-shaped holes, such as figure 1 with image 3 Shown are the laser shock peening of the edge area of the prism special-shaped hole and the laser shock peening of the inner wall; including: laser 1, laser control device 2, numerical control system 4, fixture Ⅰ 5, feeding device Ⅰ 6, five-axis table 7, Feeding device Ⅱ 8, fixture Ⅱ 9, cooperating pin 11, water tank 12 and total reflection mirror 16, this device can avoid hole edge to collapse and Figure 5 The "plasma shielding" effect shown.

[0047] The laser 1 is located directly above the five-axis table 7; the laser control device 2 is located on the right of the laser 1; the numerical control system 4 is located at the bottom right of the laser control device 2; the fixture I5 is connected to the five-axis table 7 through the feeding device I6; the fixture II9 It is connected to the five-axis table 7 through the feeding device II8; the matching pin 11 ...

Embodiment 2

[0050] The specific steps of laser shock strengthening in the edge area of prismatic special-shaped holes are as follows:

[0051] 1) Place the five-axis worktable 7 in the water tank 12 .

[0052] 2) Install the workpiece 2 on the fixture Ⅰ5, and paste a sticker such as Figure 7 Thicken the absorbing layer as shown, and then install the matching pin 11 on the fixture Ⅱ9, adjust the feeding device Ⅰ6 and feeding device Ⅱ8 through the numerical control system to make the matching pin 11 and the prismatic special-shaped hole precisely match, the minimum interference is 0.01mm , the maximum interference is 0.025mm, and the upper end surface of the matching pin 11 coincides with the upper end surface of the prismatic special-shaped hole.

[0053] 3) Set the side length of the square laser beam of the laser 1 to 3 mm, the pulse energy to 2 J and the pulse width to 20 ns through the laser control device 2 .

[0054] 4) Adjust the five-axis worktable 7 through the numerical cont...

Embodiment 3

[0065] Change the square spot laser beam in the angular region 14 in the second embodiment to: the side length is 0.5-3mm, the pulse energy is 1J, and the pulse width is 20ns, and other methods and steps remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com