A method for composting pretreatment of food waste

A kitchen waste and pretreatment technology, which is applied in the preparation of organic fertilizers, the treatment and application of bio-organic parts, etc., can solve the problems of affecting the quality of compost, hindering ventilation, easy acidification of kitchen waste, etc., to optimize the treatment process, The effect of improving the composting effect and reducing the oil and salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

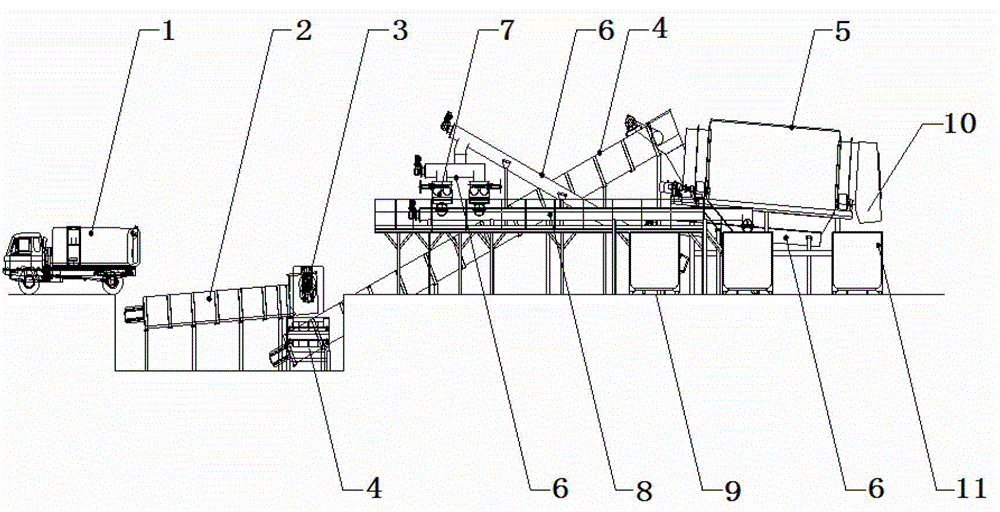

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0023] Such as figure 1 As shown, a method for composting pretreatment of food waste comprises the following steps:

[0024] 1) Feeding of food waste, the food waste is dumped by the special food waste transport vehicle 1 onto the chain plate bag breaking and conveying integrated machine 2, and the material is initially separated from solid and liquid during the chain plate conveying process;

[0025] 2) The roller bag breaking device 3 is installed at the head section of the chain plate bag breaking conveyor integrated machine 2 to cut the large bags in the material and carry out preliminary bag breaking;

[0026] 3) After the preliminary solid-liquid separation and bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com