Reaction in-situ type concrete protective agent with self-cleaning function

An in-situ reaction and concrete technology, applied in the field of building materials, can solve problems such as unfavorable large-scale application, increased material cost and dispersion difficulty, and achieve the effect of improving the photocatalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

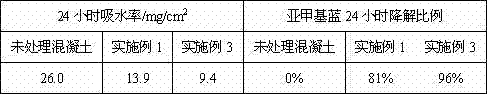

Embodiment 1

[0021] An in-situ reactive concrete protective agent with self-cleaning function, the protective material components and their mass percentages are:

[0022] Tetraethyl orthosilicate: 10%

[0023] Silane coupling agent: 0%

[0024] Nano-TiO 2 : 3%

[0025] Water: 87%

Embodiment 2

[0027] An in-situ reactive concrete protective agent with self-cleaning function, the protective material components and their mass percentages are:

[0028] Tetraethyl silicate: 50%

[0029] Silane coupling agent: 10%

[0030] Nano-TiO 2 : 15%

[0031] Water: 25%

Embodiment 3

[0033] An in-situ reactive concrete protective agent with self-cleaning function, the protective material components and their mass percentages are:

[0034] Tetraethyl silicate: 30%

[0035] Silane coupling agent: 5%

[0036] Nano-TiO 2 : 10%

[0037] Water: 55%

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com