Method for preparing monodisperse hollow meso-porous silicon dioxide nanometer particles

A mesoporous silica and nanoparticle technology, applied in the direction of silica, silicon oxide, nanotechnology, etc., can solve the problem of uneven particle size of hollow mesoporous silica, uncontrollable cavity pore size, and limit the next application and other issues, to achieve the effect of good biocompatibility, low density and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

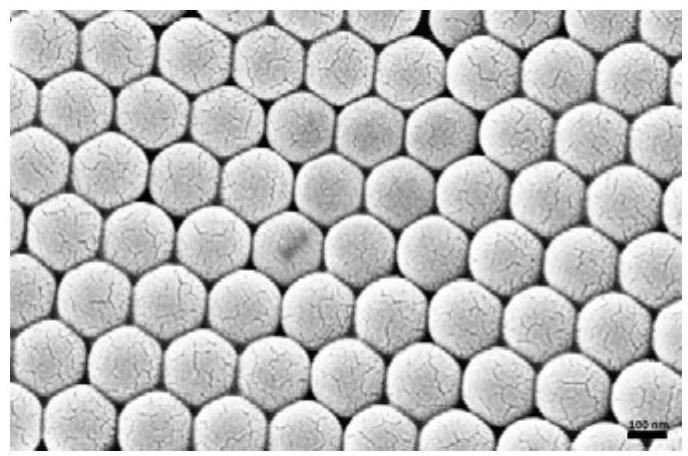

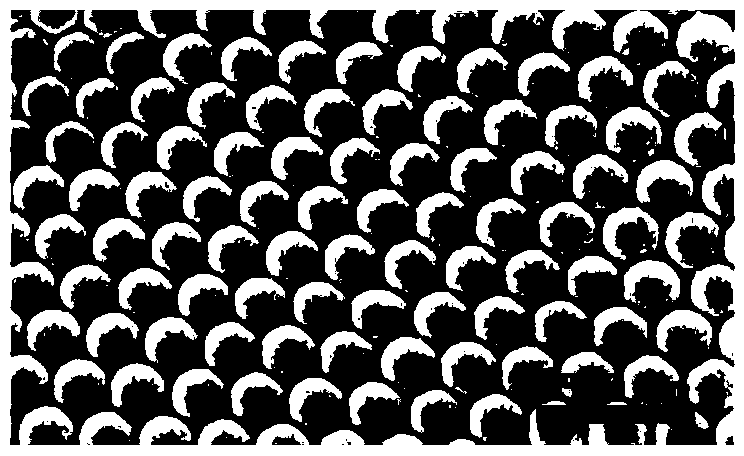

Image

Examples

Embodiment 1

[0026] The polystyrene microspheres were prepared as follows:

[0027] (1) Add 15ml styrene, 1ml acrylamide, 0.01ml G570, 500ml deionized water into the reaction vessel, stir under nitrogen protection and heat up to 70°C;

[0028] (2) After nitrogen purging for 30 min, 0.2 g of initiator was added to the reaction system, and under nitrogen protection, stirring was continued for 24 h to obtain polymer microspheres.

[0029] The preparation of hollow mesoporous silica composite microspheres is as follows:

[0030] (1) Add 1ml of polymer microsphere solution and 0.06g of cationic surfactant into 50ml of PBS buffer solution, and disperse evenly by ultrasonication for 30min;

[0031] (2) Add the mixed solution in step (1) into the reaction vessel, add 0.1ml tetraethyl orthosilicate dropwise, and stir for 5 hours at 70°C;

[0032] (3) After the reaction, centrifuge, dry the precipitate at 50°C for 1.5h, and then calcinate at 550°C for 6h to obtain hollow mesoporous silicon nanopar...

Embodiment 2

[0035] The polystyrene microspheres were prepared as follows:

[0036] (1) Add 25ml styrene, 1.5ml acrylamide, 0.015ml G570, 600ml deionized water into the reaction vessel, stir under nitrogen protection and heat up to 65°C;

[0037] (2) Add 0.5 g of initiator to the reaction system after nitrogen purging for 30 min, and continue to stir and react for 24 h under nitrogen protection to obtain polymer microspheres.

[0038] The preparation of hollow mesoporous silica composite microspheres is as follows:

[0039] (1) Add 1.5ml of polymer microsphere solution and 0.08g of cationic surfactant into 60ml of PBS buffer solution, and disperse evenly by ultrasonication for 30min;

[0040] (2) Add the mixed solution in step (1) into the reaction vessel, add 0.1ml tetraethyl orthosilicate dropwise, and stir for 5 hours at 70°C;

[0041] (3) After the reaction, centrifuge, dry the precipitate at 50°C for 1.5h, and then calcinate at 550°C for 6h to obtain hollow mesoporous silicon nanopa...

Embodiment 3

[0044] The preparation of polystyrene microspheres is with embodiment 1:

[0045] The preparation of hollow mesoporous silica composite microspheres is as follows:

[0046](1) Add 2ml of polymer microsphere solution and 0.05g of cationic surfactant into 50ml of PBS buffer solution, and disperse evenly by ultrasonication for 30min;

[0047] (2) Add the mixed solution in step (1) into the reaction vessel, add 0.2ml tetraethyl orthosilicate dropwise, and stir for 5 hours at 70°C;

[0048] (3) After the reaction, centrifuge, dry the precipitate at 50°C for 1.5h, and then calcinate at 550°C for 6h to obtain hollow mesoporous silicon nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com