Hydrogen peroxide extraction process

A technology of hydrogen peroxide and process, applied in the direction of peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, non-metallic elements, etc., can solve the problems of extraction tower accumulation, low perforation rate, Problems such as differences in mass transfer driving force, etc., to achieve the effect of increasing mass transfer rate, improving extraction effect, and improving tray efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

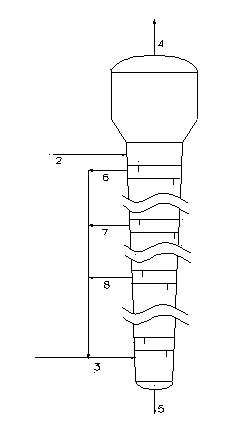

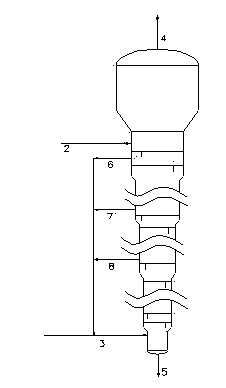

[0029] When the extraction tower is used at 100% operating load, the volume flow rate of the working fluid drawn from the production pipeline gradually increases by 4% from bottom to top, and the volume flow ratio of the total working fluid drawn out to the oxidation liquid feed is 1:80, return At the inlet of the oxidation liquid at the bottom of the extraction tower, after this process, the mass fraction of hydrogen peroxide at the bottom of the extraction tower is 29.8% to 33.5%, and the residual hydrogen peroxide content in the raffinate at the top of the extraction tower is 0.12g / L to 0.20g / L; The total amount of working fluid drawn, so that the volume flow ratio of the total working fluid drawn and the oxidized liquid feed is 1:20, and returned to the inlet of the oxidized liquid at the bottom of the extraction tower. After this process, the flow state in each layer of the extraction tower Stable, the working fluid floats evenly, the mass fraction of hydrogen peroxide at ...

Embodiment 2

[0031]When the extraction tower is used at 100% operating load, there are 4 extraction pipelines from the 25th, 30th, 35th, and 40th sieve plate positions respectively, and the volume flow rate of the working fluid drawn from the extraction pipelines gradually increases from bottom to top. Increase by 2.5%, the volume flow ratio of the total amount of working liquid drawn to the feed of the oxidizing liquid is 1:80, and return to the inlet of the oxidizing liquid at the bottom of the extraction tower. After this process, the mass fraction of hydrogen peroxide at the bottom of the extraction tower is 29.2%~ 31.5%, the residual hydrogen peroxide content in the overhead raffinate of the extraction tower is 0.12g / L~0.20g / L; change the total amount of working fluid drawn, so that the volume flow ratio of the total working fluid drawn and the oxidizing liquid feed is 1: 10. The volume flow rate of the working fluid drawn out from the extraction pipeline gradually increases by 1.0% fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com