Motorcycle head cover installation structure

A technology for mounting structure and hood, which is used in bicycle accessories, transportation and packaging, weather guards, etc., can solve the problems of increased wall thickness, shrinkage of the surface of the hood, and reduction of strength, so as to reduce surface shrinkage and strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

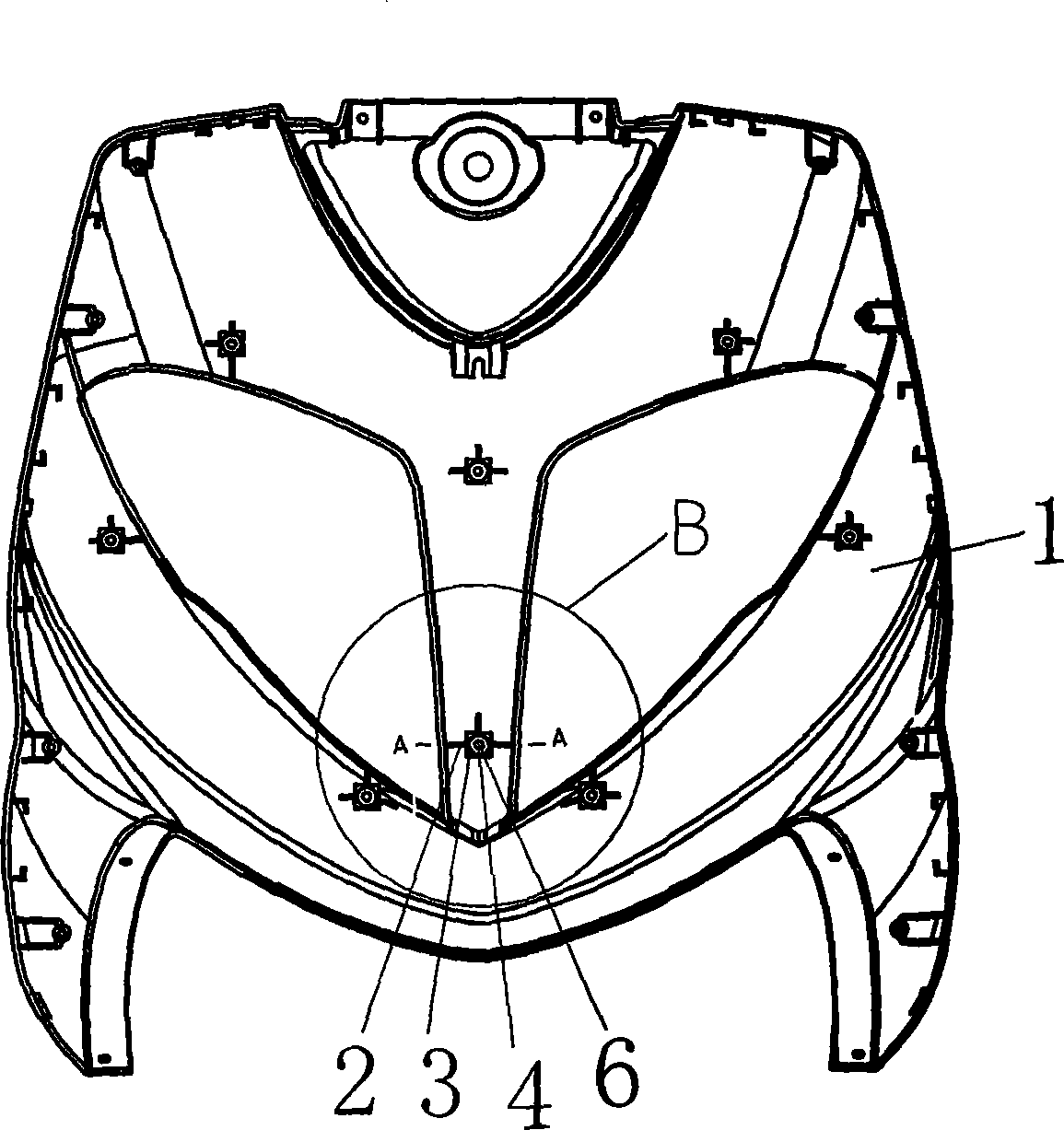

[0014] See attached Figure 1-3 , the motorcycle head cover mounting structure of the present invention comprises a head cover 1 and a mounting hole 6, the inner surface of the mounting hole 6 is provided with a mounting column 4 extending outward from the entity, and the mounting column 4 The side is provided with reinforcing ribs 2 and the roots are provided with pits 3, and the assembly column 4 is provided with an opening 5 rectangular columns near the entity of the head cover 1. The assembly column 4 is stepped, and the assembly column 4 is provided with an opening 5 close to the body of the head cover 1. The diameter of the rectangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com