Air inflation and tire repair integration machine

An all-in-one machine and tire repair technology, which is applied in vehicle maintenance, vehicle maintenance/repair, transportation and packaging, etc., can solve the problems of bulkiness and difficulty in carrying, and achieve the effects of convenient and quick operation, fast inflation time and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

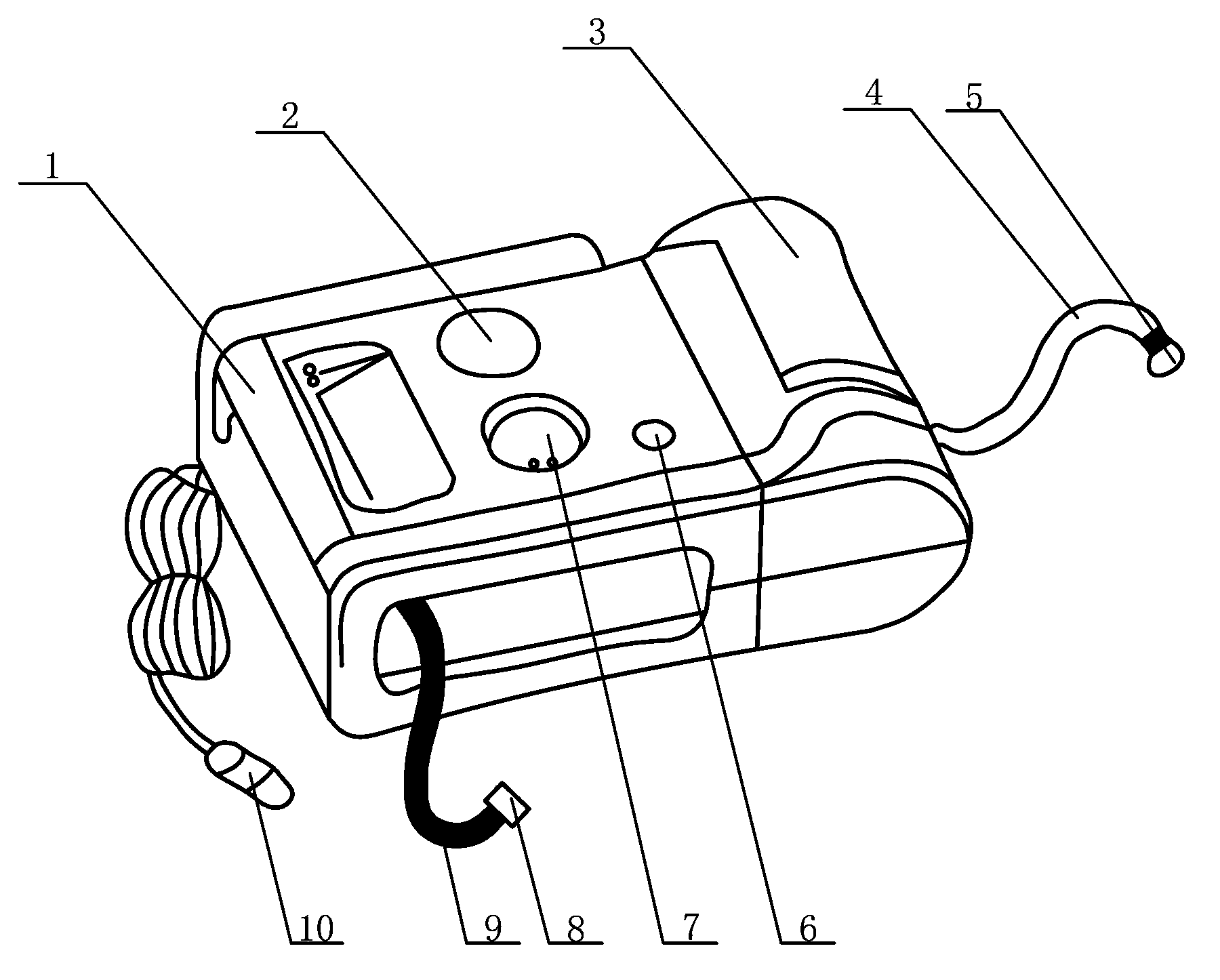

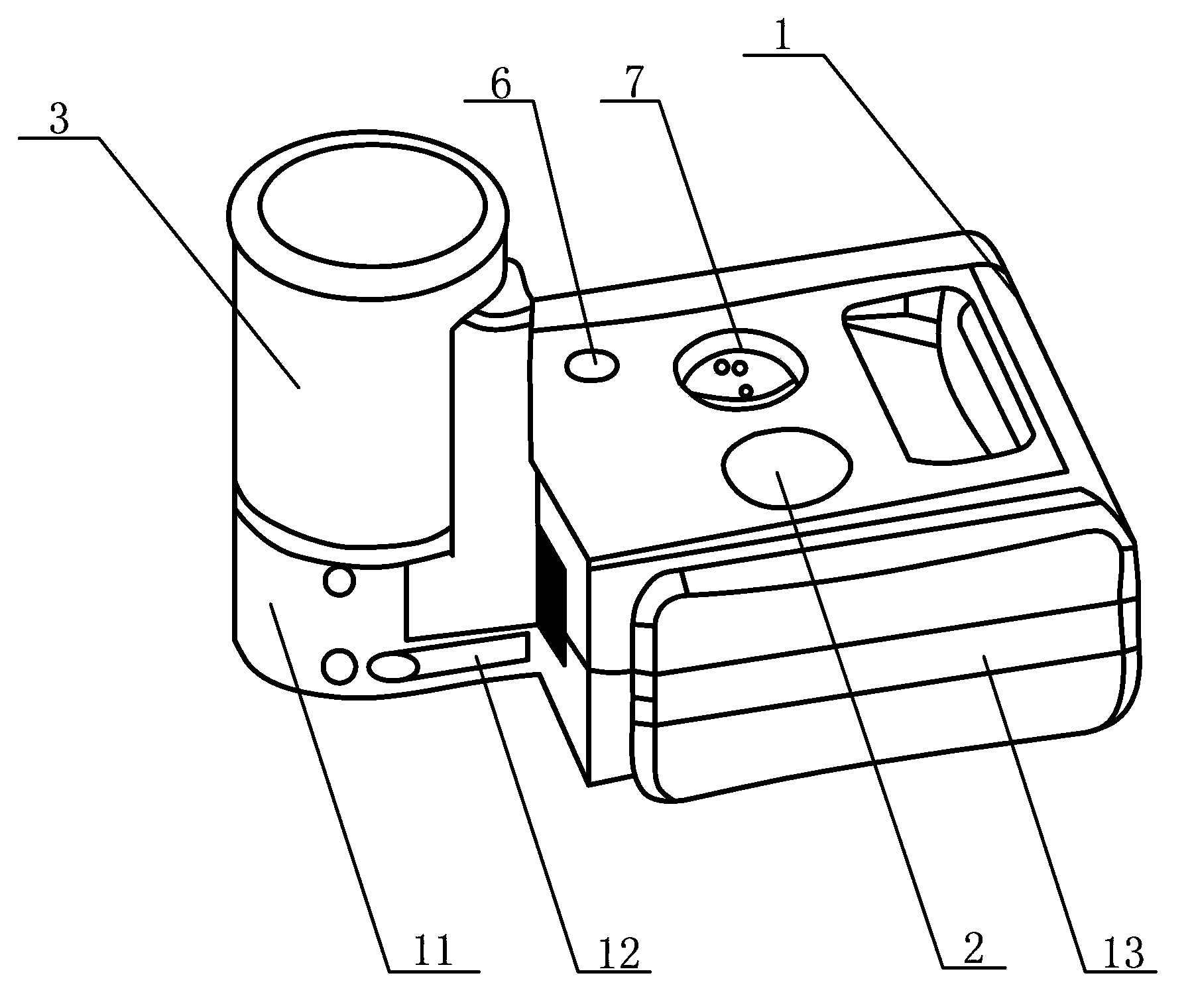

[0024] As shown in the accompanying drawings, the present invention is an all-in-one machine for tire repair, including: an air compressor 1, a pressure gauge 2, a tire repair liquid bottle 3, a tire repair liquid pipe 4, a tire repair liquid pipe joint 5, a manual air release valve 6, Switch 7, inflation pipe joint 8, inflation pipe 9, cigarette lighter joint 10, tire sealant fluid system 11, tire sealant fluid system joint 12, night light 13. The air compressor 1, the pressure gauge 2, the inflation pipe plug 8, and the inflation pipe 9 jointly form the inflation device; the tire repair liquid bottle 3 and the tire repair liquid system 11 form the tire repair device. The inflation device and the tire repairing device jointly constitute an all-in-one machine. Wherein, the tire sealing fluid system 11 is rotatably installed on the housing of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com