Method and control unit for activating actuators of a vehicle during emergency operation

一种执行器、运行中的技术,应用在执行器领域,能够解决未被提供、不经济等问题,达到避免减速效果、成本节省、结构空间节省的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

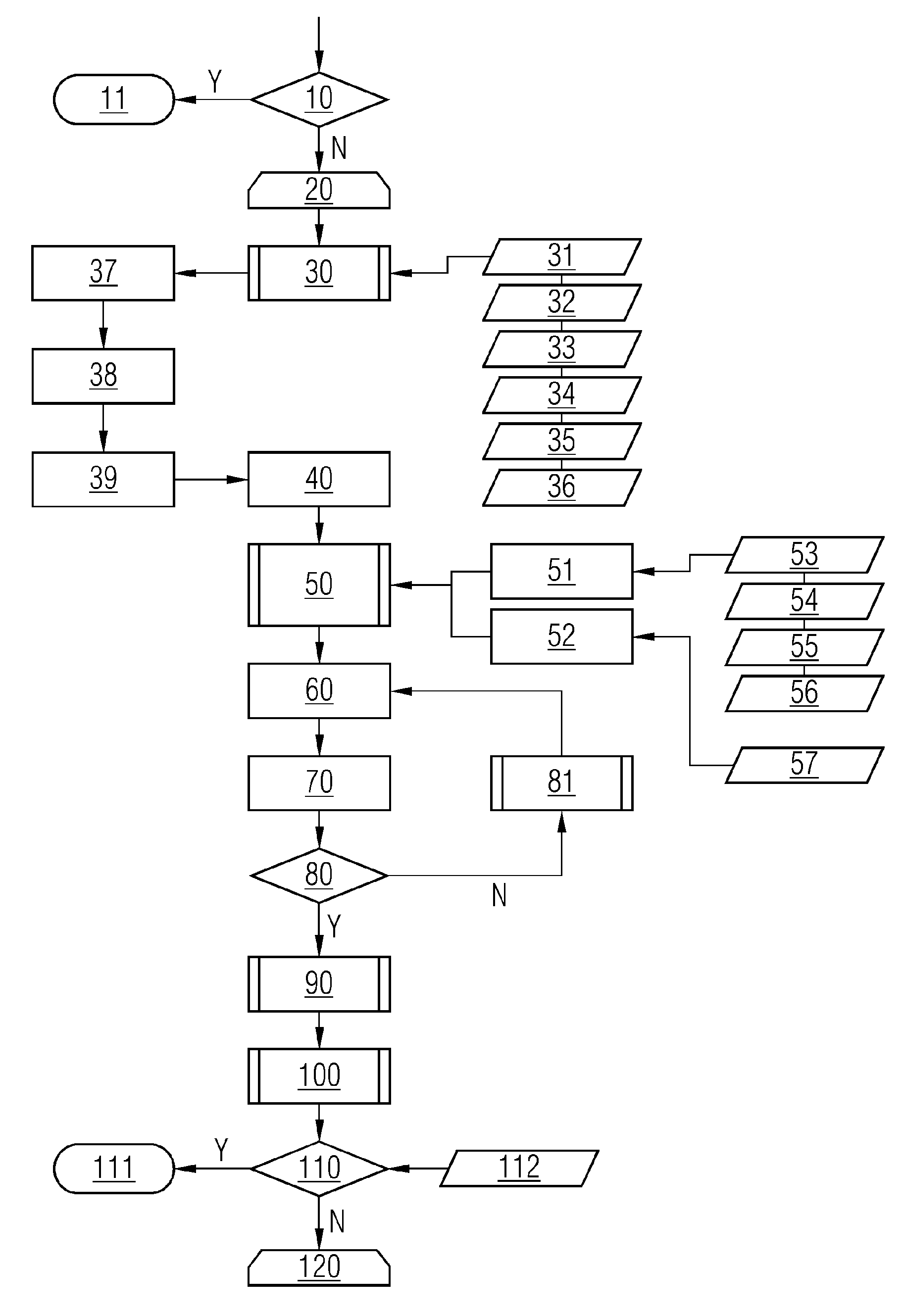

Method used

Image

Examples

Embodiment Construction

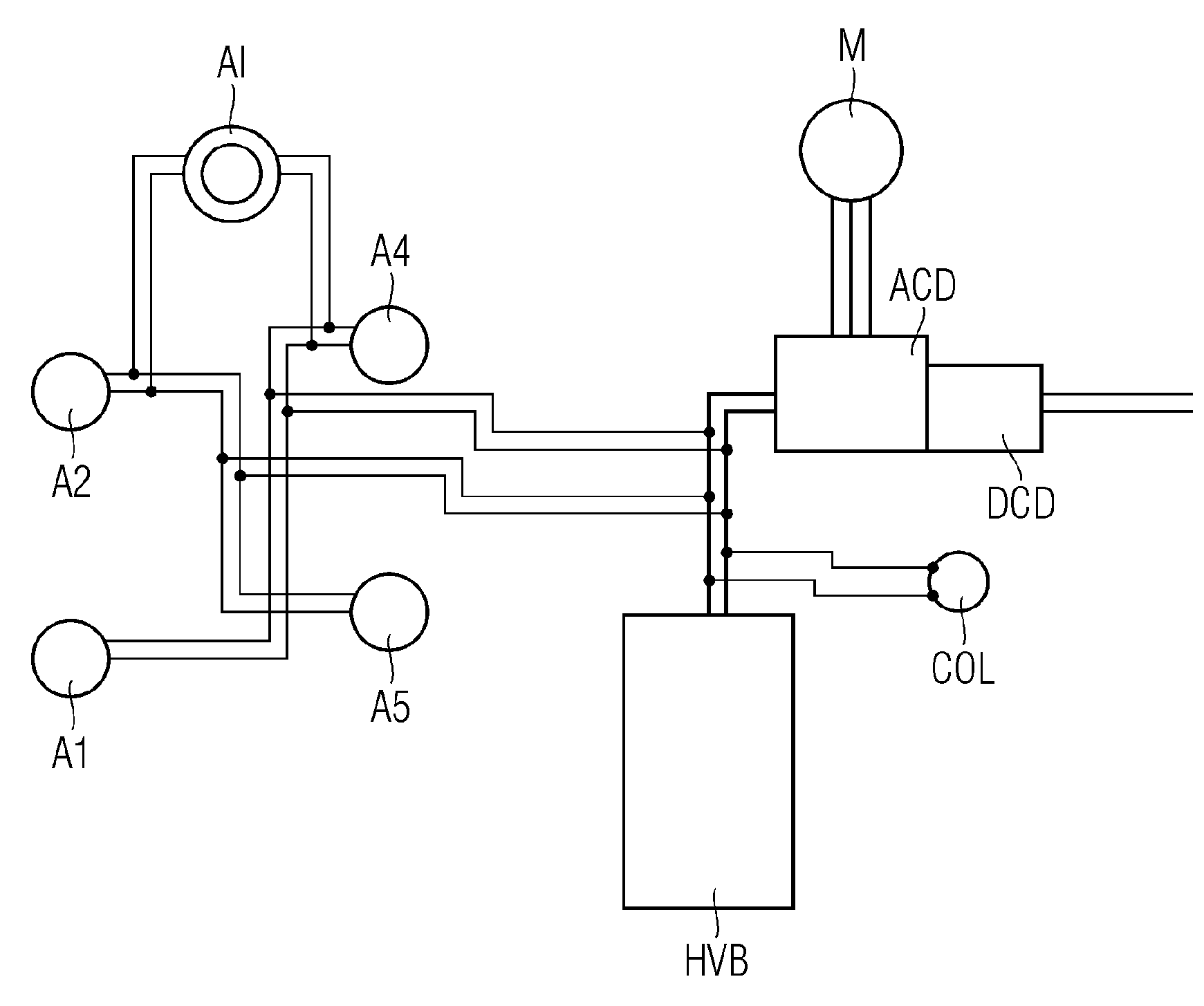

[0045] figure 1 A schematic structure of a multi-voltage vehicle power supply in a vehicle known from the prior art is shown. basically occupy figure 1 A high voltage power supply is shown in the diagram of the entire space.

[0046] A drive accumulator HVB, a plurality of actuators A1, . An electric driving machine M. A voltage conversion of the high-voltage supply voltage, for example 400 or 800 volts direct current, into a vehicle supply voltage provided for the low-voltage supply takes place via the DC transformer DCD. A DC voltage of up to 12 volts is typically provided for the low-voltage power supply. The low voltage power supply is only passed through the figure 1 Symbolically indicated by two parallel extending straight lines in the right edge of . In this professional field, the concept of secondary power supply is sometimes referred to in relation to low-voltage power supply.

[0047] An actuator in the sense of this description is to be understood as an elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com