A kind of hybrid power system and its control method

A technology of hybrid power system and engine, which is applied in the direction of control device, power device, air pressure power device, etc. It can solve the problem of difficulty in meeting the needs of normal driving of general vehicles, limited engineering application range and value, increased system size and control difficulty, etc. problems, to achieve the effect of mature and reliable production technology, avoiding frictional energy loss, and optimizing engine working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

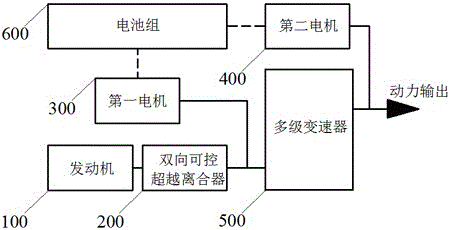

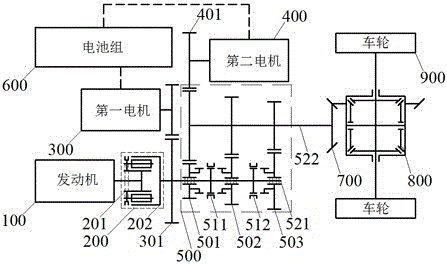

[0047] figure 1 It is an embodiment of the present invention. The following further describes the realization method of the present invention. Of course, the total number of gears of the transmission may not be limited to 3 gears.

[0048] The hybrid power system of the present invention includes an engine 100, a two-way controllable overrunning clutch 200, a first motor 300, a second motor 400, a multi-speed transmission 500, a battery pack 600, one end of the two-way controllable overrunning clutch 200 and the engine 100 The output shaft is connected, the other end of the two-way controllable overrunning clutch 200 is connected to the output shaft of the first motor 300, the active part of the multi-speed transmission 500 is connected to the two-way controllable overrunning clutch 200, and the driven part of the multi-speed transmission 500 is connected to the second The output shaft of the motor 400 is connected, and the battery pack 600 supplies power to the first motor 300 an...

Embodiment 2

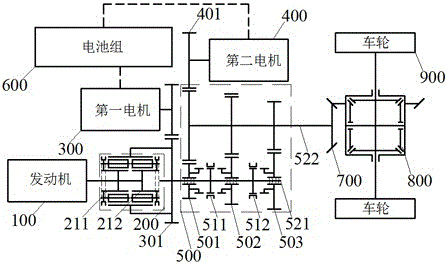

[0089] This example image 3 As shown, the two-way controllable overrunning clutch 200 in this embodiment is formed by a combination of a one-way controllable overrunning clutch (forward) 211 and a one-way controllable overrunning clutch (reverse) 212. Four types of the two-way controllable overrunning clutch 200 Table 1 shows the corresponding relationship between the working modes and the modes of the one-way controllable overrunning clutches 211 and 212. Relatively speaking, the one-way controllable overrunning clutch has simple production process, low manufacturing cost and reliable operation.

[0090] Table 1 Comparison of working modes of two-way controllable overrunning clutch and one-way controllable overrunning clutch

[0091] Two-way controllable overrunning clutch One-way controllable overrunning clutch (forward) One-way controllable overrunning clutch (reverse) Fully integrated (mode one) Enable Enable Reverse enable (mode 2) Disability Enable Complete separatio...

Embodiment 3

[0093] This example Figure 4 Shown. The ordinary one-way overrunning clutch 220 in this embodiment is equivalent to the two-way controllable overrunning clutch 200 having only a forward enable mode (mode 4). Due to the power transmission characteristics of the one-way overrunning clutch, in this embodiment, the engine 100 A starter is needed to start the engine.

[0094] From the perspective of practical engineering applications, two points need to be pointed out in particular. The first point is that when the ordinary one-way clutch 220 is in the overtaking state for a long time, the transmission parts of the ordinary one-way clutch 220 will be worn out. If the wear is severe, it will cause failure. The second point is that the output of the engine 100 has torque fluctuations, and the ordinary one-way clutch 220 that can only transmit power in one direction may cause additional vibration, thereby affecting the stability of the power output of the system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com