Chassis with adjustable transverse wheel tread and adjustable ground clearance and adjusting method of chassis

A technology of ground clearance and chassis, applied in elastic suspension, interconnection system, suspension and other directions, can solve the problems of poor running stability of the chassis, inclination of the chassis, inability to adapt to the requirements of different ridge widths, etc. The effect of uneven ground in the field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

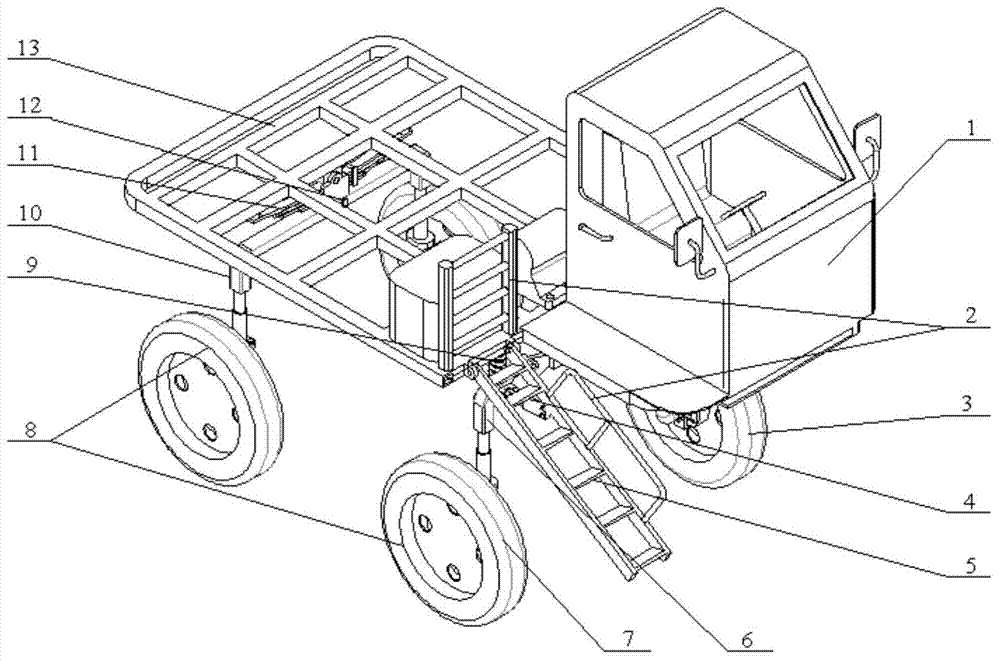

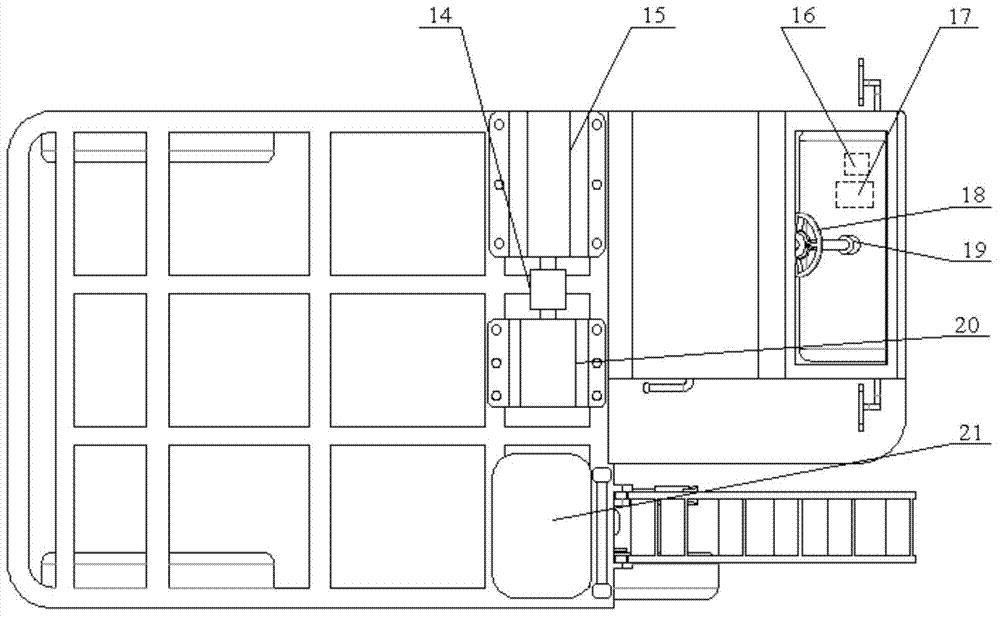

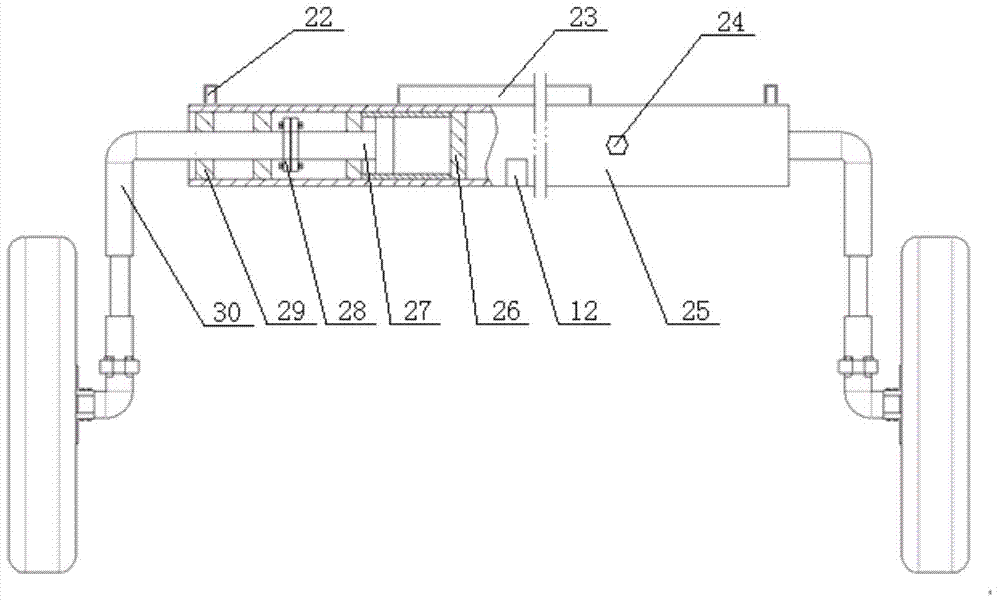

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] The cab 1 is connected to the vehicle frame 13 , the front axle 6 is hinged on the vehicle frame 13 through the front axle connecting block 23 , and the rear axle 10 is hinged on the vehicle frame 13 through the rear axle connecting block 37 . The liftable ladder 5 realizes the lifting of the ladder 5 through the movement of the lifting hydraulic cylinder 4. The liftable ladder 5 is connected to the vehicle frame 13 through a hinge, and the liftable hydraulic cylinder 4 is hinged to connect the liftable ladder 5 and the front axle 6. The handrail 2 ensures that the driver can go up and down. car safety.

[0023] In the pumping station 20 , the engine 15 is connected to the vehicle frame 13 through bolts, and the engine 15 is connected to the pumping station 20 through the clutch 14 .

[0024] The pump station 20 drives a hydraulic motor 36, and the hydraulic mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com